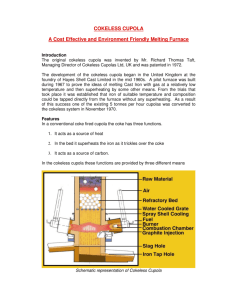

Energy efficient and environmentally friendly cupola furnace

advertisement

Energy efficient and environmentally friendly cupola furnace Prosanto Pal and Abhishek Nath TERI, Habitat Place, Lodhi Road, New Delhi 110003. Tel: 011-4682100 or 4682111, Fax. 011-468 2144 or 468 2145 Email: mailbox@teri.res.in Background There are over 6000 small-scale foundries in India. Most of these foundries are concentrated in geographical cluster. The foundry industry is characterized by its high energy consumption and particulate emissions. Melting is the most energy intensive process in foundries and also results in release of major air contaminants. Cupola furnaces, is by far, the most common type of melting furnace in Indian foundries. Majority of the cupolas in operation today are based on conventional energy inefficient designs. Rising cost of energy inputs, increasing competition and environmental pressures are serious threats to the survival of foundry units today. In order to popularize an energy efficient and environmentally friendly cupola among Indian foundries, Tata Energy Research Institute (TERI) has set-up a demonstration cupola melting plant at a foundry unit, nominated by Indian Foundry Association (IFA) in Howrah. After setting-up of the model unit, TERI has been trying to disseminate the demonstrated technology to other foundries in India. The paper outlines the improvement in energy and environmental performance possible through adoption of a properly designed divided blast cupola (DBC) and pollution control device. Initial diagnosis Energy audits of a range of cupolas were conducted by TERI in Howrah and Agra foundry clusters. The charge coke percentage, which is a measure of energy efficiency of a cupola, was found to vary over a wide range. The most energy efficient cupola was found to be using 13.6 percentage charge coke (coke:metal :: 1:7.5) and the least energy efficient cupola was operating at a charge coke percentage of 26.5 (coke:metal :: 1:4). Some of the factors that contributed to the poor energy performance of operating cupolas were found to be the following: § Incorrect blast rate § Lower blast air pressure § Incorrect distribution of air between the top and lower tuyeres § Turbulent (non-uniform) entry of air into the cupola § Incorrect sizing of cupola parameters such as tuyere area, well depth, and stack height among others § Poor operating and maintenance practices § Poor control of feed materials (shape, size, weight, sequence) Advantages of DBC Divided blast cupola (DBC) is a well-proven technology for improving the energy performance at a modest investment. As si evident from its name, a DBC supplies blast air to the cupola furnace at two levels through a double row of tuyeres. The blast air is almost equally divided between the top and bottom row of tuyeres, and the spacing between the tuyeres is about one metre apart, irrespective of the diameter of the cupola. Some comparative advantages of a DBC, as found in studies conducted by BCIRA, are given below: § a higher metal tapping temperature (approximately 45-50oC more) and higher carbon pick-up (approximately 0.06%) are obtained for a given charge-coke consumption § charge-coke consumption is reduced by 20-32% and the melting rate is increased by 11-23%, while maintaining the same metal tapping temperature. However, in the initial survey conducted at Agra and Howrah foundry clusters, it was found that conventional cupolas are commonly used by Indian foundry units and DBCs, where ever adopted, are of sub-optimal designs. Hence the intervention aims to demonstrate and disseminate the benefits of a well designed DBC among Indian foundries. TERI's DBC design TERI's DBC design incorporates the specific melting requirements of the individual foundry unit. Salient features of the cupola design include: § Optimum selection of blower specifications (quantity and pressure) § § § § § § § § Optimum ratio of the air delivered to the top and bottom tuyers Minimum pressure drop and turbulence of the combustion air Separate wind-belts for top and bottom tuyeres Correct tuyere area, tuyere number and distance between the two rows of tuyeres Optimum well capacity Higher stack height Mechanical charging system Stringent material specifications Energy savings and other benefits A demonstration plant was installed at Bharat Engineering Works, Howrah, a unit nominated by the Indian Foundry Association (IFA). The foundry, manufacturing ingot moulds, had a charge coke percentage of 13.6 percent (coke:metal :: 1:7.5) which was brought down to 8 percent (coke:metal :: 1:12.5). Hence, the energy saving achieved in the new plant was about forty percent co mpared to their earlier cupola. On an average monthly melting of 430 tons, the yearly saving in coke is 270 tons which is equivalent to Rs. 8 lakh. Additionally there was an increase in metal tapping temperature and reduction in silicon and manganese losses. Energy saving of about 40 percent was achieved in a replication unit set-up at a foundry unit in Nagpur which make thin walled sanitary castings. The charge coke consumption reduced from 22 percent (coke:metal :: 1:4.5) earlier to about 13 percent (coke:metal :: 1: 7.7) . This translates to a coke saving of 280 tpa worth about Rs. 11 lakh on a melting of 300 tons per month in the foundry. The total capital investment of the cupola, inclusive of civil work, platforms, bucket charging system etc.) was about Rs. 12 lakh. Thus the payback on the investment is one year considering saving in coke only. Additional benefits of the DBC were better analytical and temperature control of molten metal leading to substantial reduction in rejection of finished castings. The payback is more attractive if the decrease in rejection rate of finished casting on account of better analytical and temperature control is considered. 70 65 Energy saving (%) 60 50 40 30 20 35 40 25 10 0 Cupola at Howrah Cupola at Nagpur Range of saving expected in other cupolas Comparison of energy performance Pollution control device Environmental measurements were carried out by TERI at different locations to assess the emission level of untreated cupola stack gases. The suspended particulate matter (SPM) emissions without any gas cleaning device was found to vary in the range of 1300 mg/Nm3 to 3900 mg/Nm3 . The measu rements show that the emissions from cupola are much higher than the statutory limits and hence a pollution control device needs to be installed along with the cupola to comply with environmental regulations. TERI's venturi scrubber system The venturi scrubber is a highly efficient device for removing particulate matter and sulphur dioxide from stack gases. Since cupola stack gases contain a significant percentage of fine particulates, it was found that a venturi scrubber is the most effective device to bring down the emissions below the more stringent particulate emission limit of 150 mg/Nm³. Some of the salient features of the venturi scrubber design are: § Variable venturi throat to clean the gas by binding the particles to water droplets § Optimum gas velocity at the throat, liquid/gas ratio and throat geometry for maximum efficiency § Dewatering cyclone after venturi to retain water droplets in the gas stream § Induced draft fan to ensure sufficient pressure drop § § § § Stainless steel construction to prevent corrosion Closed circuit recirculation to minimize water requirement Lime dosing to maintain the pH of the recirculating water Explosion doors and gas tight construction to prevent explosion SPM and sulphur dioxide of the outlet gas from the pollution control device installed at a foundry in Howrah was measured. The SPM was found to be about 50 mg/Nm3 and sulphur -dioxide was measured to be about 40 mg/Nm3 . The results have been validated by the monitoring done by the pollution control authorities independently. Bharat Enginerring Works, Howrah, the foundry unit where the pollution control device is installed, has recently won the prestigious Environmental Excellence Award 2000-2001 given by West Bengal Cleaner Production Centre, set up jointly by the Indian Chamber of Commerce and the West Bengal Pollution Control Board. Comparison of suspended particulate matter (SPM) emissions Conclusion The results of the demonstration project show that there is a huge potential for energy saving and pollution reduction among foundries in India. Technical assistance for the design and implementation of energy efficient cupola melting furnace is available at subsidized cost to foundry units desirous of upgrading their melting units. The following services are provided to t he foundry units by TERI: • Energy and environment audit of their existing cupola • Design of DBC and pollution control device • Advisory support during vendor selection, fabrication and installation • Assistance during test firing and fine-tuning of the plant • Training of operators on best operating practices • Post implementation energy and environment audit to quantify energy savings and environmental performance. Services of the best available international foundry technology expertise can be availed by the Indian small scale foundry units at subsidized cost, since the intervention is supported by the Swiss Agency for Development and Cooperation (SDC). It is hoped that the Indian foundry industry would avail of the services being offered to modernize their melting operations.