Foundry Consultation - Experts

advertisement

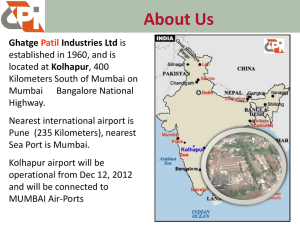

Foundry Consultation - Experts - With Success Solutions Who we are ? We are a group of foundry-men who have worked in Foundries with a wide experience of over 40 years in the field. We are providing services in India for International foundries ◦ Teksid France,Brazil,Poland,Italy ◦ Mazzuconni Italy ◦ Hua Dong Teksid Automotive Foundry Company Ltd ◦ Hongteo accurate Technology Co. Ltd Who we are ? The team is headed by Mr. Bhasin with Mr. Sherkar and Mr. Sohoni as team members. The team is supported by Mr.Parvinder singh & Mr.V.M.Rao Expertise : Mr.S.S.Bhasin • He has done his Engineering from Bits Pilani. • He has a wide experience of over 40 yrs in the Total Foundry management, Maintenance systems, Project Management & Product development. • He has worked as Foundry in-charge of all the foundries of Tata motors. • He was CEO – Foundry of Kores India Ltd. • He has also worked in the organizations like RICO – Gurgaon, SEACO – Pune. • He has also undertaken assignments of the groups like Bharat Forge – Pune, Simplex Castings –Raipur. • He has also dealt with overseas tie up for TATA Motors. • He has extensively travelled abroad and visited various foundries. Expertise : Mr.Sherkar He has Extensive experience in Tata Motors for reconstruction of Tata Maval Foundry. He was key player for complete erection and development of the Tata Maval Foundry. He has also worked in the organizations like M&M – Swaraj Foundry – Mohali, Kores Ind Ltd, SEACO. He has worked on projects in gulf countries. He has over 30 years experience in foundry projects. Expertise : Mr.Kiran Sohoni He has done metallurgy engineering from College of Engineering Pune . He is having wide experience in the field of Foundry processes like sand casting, No Bake, Hand Molding etc. He has worked as general manager in the organizations like Hero Group, Kores Ind Ltd and Jindal group and also worked in the organizations like Tata Motors, Force Motors, Jayahind Industries. He has over 20 years experience in product development, process control & foundry management. Expertise : Mr.Parvinder Singh • He has done engineering from College of Engineering Pune . • He has over 35 years experience in various forming industries including foundry. • He has expertise in machining providing solutions & dealing with overseas foundries. • He has coordinated Italian equipment suppliers for highly automated aluminium foundries for cylinder heads at TATA Motors Pune. Verticals Exposure We as a group have extensive experience in grey iron, nodular iron, aluminium foundries covering project planning, project execution, product development, efficiency improvement, cost control, process management etc. We have experience of dealing with auto commercial vehicles passenger car, tractor, twowheeler, electrical, windmill, engineering, sugar, heavy castings etc. Processes Exposure Green Sand process - hand molding and machine molding, no bake Process, full mold process, shell molding. Die Casting process– gravity, high pressure & low pressure Molding process: Horizontal and Vertical flask-less molding machines like KOYO, DISA; Jolt Squeeze molding machines, Continuous mixers for No Bake process; Sand plant: All types of mixers, coolers like Kunkel-Wagner, Erich, conventional; other allied equipments. Melting process: Coreless induction furnaces – medium and mains frequency; Cupola; Holding furnaces; Press Pours; Auto pours; all types of linings. Processes exposure Core making process: Vertical and Horizontal shell core making; Vertical and Horizontal cold box core making; Hot box core making; No bake core making; Co2 core making. Pattern shop: Wooden patterns, Metallic patterns, Epoxy patterns, Permanent dies; Core setting fixtures; Match plates; Milling machines ( manual and cnc base ). Finishing operations: Continuous and hanger type shot blasting machines; Special purpose trimming machines; Gate cutting machines. Peripheral equipments: Compressors; Generator sets; Dust extraction units; Pump house; Gas plant. Alloys handled: Cast iron ( all grades ); S.G.Iron ( all grades ); Alluminium Services offered Preparing Project Report comprising of: 1) Selection of technology, product, equipment, process etc, 2) Layout, building, and other utilities like air, water, power, gas etc 3) PROJECT cost details. 4) Time line of project activities. 5) Tooling requirement/budgetary cost/timeline. 6) Manpower requirement/organization structure. 7) Raw materials requirement/budgetary cost per unit. 8) Statutory clearances required. Consultation for the following • Improvement in Production. • Breakdown reduction. • Rejection Control. • Maintenance Planning and execution. • Defining the Process Layout and raw material selection. • Defining Product and process specification. • Cost control,Value Engineering, Yield Improvement, 5S implementation, POKAYOKE, TPM etc • Preparing documentation and implementing Quality systems like ISO9000, TS16949, SPC • Conducting internal Audits Quality, Production, Maintenance systems and subsequent suggestions for improvement. • Development of new components along with APQP and PPAP documents. • Guidance for following safety practices in Plant and preparing safety SOP. Further services Implementation from green field to production. • This will involve regular interaction with architect/building contractor/equipment suppliers/erectors/project team. • We can also provide services for manpower selection/training/safety to your hr team. • We can also provide help in your customer approvals. Contact Us Mr.S.S.Bhasin ◦ Ph no : +91 98220 28716 ◦ Email id : satinder.bhasin@rediffmail.com Mr.Parvinder singh ◦ Ph no : +91 98500 09155 ◦ Email id : pftwopftwo@gmail.com Mr.Sherkar ◦ Ph no : +91 91580 07876 ◦ Email id : drsherkar@gmail.com Mr.Kiran Sohoni ◦ Ph no : +91 99224 29689 ◦ Email id : knsohoni@yahoo.co.in ◦ Visit Us on : www.ezar.in