novacast - Stanford University

advertisement

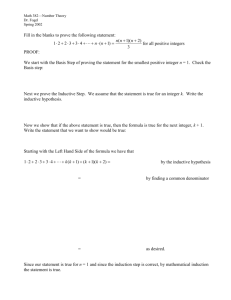

■f NOVACAST Specialists in Foundry Technology Industrial Computer Software Expert Systems Prof. Edward Feigeinbaum Ronneby 870728 Dep. Computer Science Stanford University CA 94305 Dear Prof. Feigenbaum, !_ pleasure to meet ou in London together with It the n? "Inductive interest group" meeting. W D.Michie at I promised to send you some information about successful expert systems that we or our clients have developed here in My company NOVACAST is a consultant company, established 1979 Our speciality is metallurgy and foundry technology. Our first "expert system" was a program called "Novacast Foundry Technology" that we started to market 1980. That program was written in basic and contained knowledge about the foundry process to be used by methods engineers when selecting casting processes. At that time we were not aware of the "expert system" concept the program was thus designed from zero and contained our knowledge represented as a mixture of normal calculations and then rules. The program was the first of its kind and was well recieved. Since then the program have been improved and extended several times and is nowadays mainly delivered for the IBM PCrs and is in use at more than 200 foundries worldwide. The foundry process in very complex with more than 2000 variables affecting the end result. A lot of the knowledge is still scientifically unknown and normally a lot of trial and error is used. In the knowledge acquisition phase we have been able to reveal interactions and to make practical knowledge explicit by using inductive methods. Thus in our own systems we have mainly used the inductive "example learning method" as a problem solver and hypotesis tester. We have made several other system for foundries such as: - SANDMASTER plants in - an expert foundries. system for process control of green sand - NOVASHOT an expert system for gating design in high pressure diecasting of aluminum and sink alloys. Recently we have launched a system for analysis of casting defect. The system is build with SuperExpert Professional which is a new ITL product where we have been involved in the development. The Casting Defect Analyser finds the primary cause for the defect and suggests a remedy. In 1986 I had the opportunuty to present a paper about our expert systems for foundries at the annual conference of American Foundrymen Association 1986 in Milwauki. We feel that our industrial experience and general knowledge problem solving" have been very about valuable when developing expert systems. Thus we have in the last two years expanded our activities to also include consultancy for building expert systems for clients in other sectors. NOVACAST AB FRIDHEMSVAGENB " SOFT CENTER S-372 00 RONNEBY ■ SWEDEN TEL: 0457-718 00 BG: 544-9855 ■ TLX: 43583 Novacast Page 2 toother system that is in use is our advice or, how to send letters and packages "MAILWHIZ" which gives by uses all the possibilities and "crepholes" mail. The system in the Swedish Ma__ Regulations in order to find the cheapest way depend," ?h_ and alS Sh WS *at We at miLmzz is ca P^le of reducing our m__._A.ats LT% "f It TL o! docLentHre needed ° ° alternatives if _ F COTSiStentl * *-«-. was orginally made in Expert-Ease but 0^ system smart way "smart wav The al_ is now upgraded to SuperExpert and is beeing marketed. mSL^'V^?^"" * " methods -i-rinductSn. _nnL_tive P t we have been able to reveleal rules that where not known th haVe 3 V6ry hi Predict!" STOCKMASTER has been in daily use since January 1987 Traversum albSenS bSen b Ught by two Swedishtonks. at TraVerSUm 6 lnCreased from 60 to around 90 % for one of the STO^TThasl^ /\ Tt _tft" T ° users! ° Enclosed please find a paper about documentation about our products. are We __c«_^ * STOCKMASTER and some other otner you probably know, the representative for ITL in We have been using the ITL inductive tools for our own needs since 1984. During that time we have the opportunity to tackle a variety of problems, which has given in our . Our customers represent a wide variety of as Scandinavia and Switzerland. "stomerr"^ hid *"* supporting' "* "* branches U B_nk manufacturing _ha_ma_r aCar' m Stef ""V*"*"**. Urln9 MrCraft«*^" act-ing. SstitutrshlpySdsHtc " ' Our Credit experience is that inductive shells like Exnert- *■»__ SuperExpert and Extran can be regarded not only rf l >^l-olvers" P ncra rs for or knowledge acquisition. Inductive shells are 8 t0 kn WledgS 1 tradition.! "r.lHenStols" t£i_ *° f "r.le blsed^ystet ? T «_Srt 31. „" °" ° " -» " "* Several companies are using the induction mechanism in solvi" complex problems where traditional mathematical or methods have failed. A typical case is when a lot of test data is available, some of it as logical attributes and where the of relations vary within the problem which might also be statistical compoled " _ Z_ ?°?J?" 6XP6rt add his knowledge interactively hUS flnd the mles The V inductive shell will in that case act as an "intelligence amplifier" Jn?w finding and proving hypotheses. - ° Ca and assist assist in in Novacast Page 3 Here are some examples: 1. A manufacturer of high alloyed steel tubes had a problem with an application where a customer experienced problems when welding tubes for heat exchangers. The problem was that gas blows and cracks sometimes occured in the welds. A lot of test data was available and about 10 factors were considered as being of interest. Among these were Voltage, Amps, Type of electrode Welding speed. By entering examples using class values OK, blow and crack in Expert-Ease the conditions for defect-free welds was revealed by analysing the induced rule. It was found that only 3 factors had to be kept within certain limits in order to obtain good welds. 2. A research institute has made a system using Expert-Ease that can predict the liquidus and solidus temperatures for steel alloys The system is used when trying to develop new alloys and allows engineers the to simulate the effect of various compositions. It replaces to a large extent test melts and thermal analysis. The system was developed by entering values for alloys with known compositions and their resulting liquidus and solidus . temperatures 3. A . system institute to tool steels. has also been developed by the same research optimize chemical analysis and heat treatment for 4. Optimal parameters for laser hardening of tool steels have been identified by using Expert-Ease. A system has been developed where the settings for the laser are advized depending on type of alloy, hardening depth ,etc. The engineers who developed the system had started using traditional methods but without success. The final solution revealed by Expert-Ease was astonishingly simple and to the engineers an "aha! "-event. The rule was converted to a "laser hardening diagram" and is now used daily. 5. An advisory system has been built by a tool steel manufacturer to select the optimal type of tool steel in each particular case. The expert system asks the user questions such as "Maximum operating temperature?", "Number of cycles per hour?", "Type of plastic to be injected?" etc. and can select from among the 15 different alloys. 6. A margarine manufacturer has made a system that predicts the percentage of solids in margarine mixtures at 4 different temperatures. The system considers the effect of 15 components. This is a very complex problem as all the components are soluble in each other and as the resulting solid phase is not possible to predict using normal math methods. (An analogy in metallurgy would be to construct a phase diagram with 15 components ! ) By being able to predict the resulting solid phase it is now possible to in advance add "modifiers" and mixing . thus save time Novacast Page 4 7. A manufacturer of organic lubricant oils has used Expert-Ease is a complex task where no successful methods have been published. In this case a useful approach has been developed by using Expert-Ease and analysing the induced rules. Three different systems have been developed, namely: as a research tool in formulating emulsions. This a. Investigation of the influence of 7 important variables on the stability of emulsions. b. Identifying optimal circumstances and selecting emulgators. From viewing the rule it has been possible to draw "maps" showing stable areas for the emulsions. c. A system has been developed where the performance of various emulgators can be studied. This company has also used Expert-Ease in order to extract knowledge from published articles. It has for instance been possible to extract "hidden" knowledge from experimental tests published in the traditional "row and column" format and to make it easily understandable. 8. A cancer researcher has used Expert-Ease in order to evaluate the prognostic value of various tests. Using a complete set of data from 75 patients it was revealed that the same prognostic results as with the traditional expensive tests could be achieved by checking easily observed factors such as type of tumor, size and location. A system has also been developed to find the optimal of chemo therapy and radiation treatment. combination 9. A company that manufactures ventilation and filter equipment has built a system that acts as a "risk analyser" for new projects. Ther object is to trace "problems" before even quoting a new project which often runs about 10 to 30 million Pounds so that correct allowance in both time and money can be made from the start to avoid economical losses and unfulfilled time plans etc. 10. A Swedish bank has made an investment advisory system and a system for credit application and policy. They are also working on a "legal advisor". - 11. Our representative in Finland - Wasamation AB have been using Extran and in cooperation with doctors at ABO university been able to find combinations of symptoms that have a very high prognostic value for so called "sudden death of newly born babies". The results are soon to be published in a scientific paper. This we believe is a good example as statistical methods did not reveal any significant correlation but the induction did. We have found this to be true in many cases where several descrete function are overlapping in a problem and where the limits are unknown. Thus induction can be used as a "hypotesis finder". Once the rules and the limits are known traditional methods can be used for further refinement. (■ Novacast Page 5 r Several other systems are in use in Scandinavia. We estimate that around 50 systems of practical value have been developed on this market. We have just recently started an application club and we hope to be able to catalogue the various applications in more detail . Please let me know if you need any further information. Sincerely. Rudolf Val. Sillen President Novacast AB cc: Prof. Donald Michie - ITL Encl. Various papers : Stockmaster, Building PC-housted systems, Novacast broschure, Print Screens from Casting expert Defect.