Durachrome™ Hard Chromium Plating

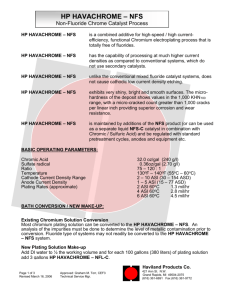

advertisement