HP_HAVACHROME_-_NFS

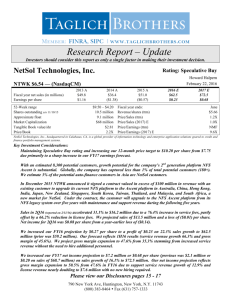

advertisement

HP HAVACHROME – NFS Non-Fluoride Chrome Catalyst Process HP HAVACHROME – NFS is a combined additive for high-speed / high currentefficiency, functional Chromium electroplating process that is totally free of fluorides. HP HAVACHROME – NFS has the capability of processing at much higher current densities as compared to conventional systems, which do not use secondary catalysts. HP HAVACHROME – NFS unlike the conventional mixed fluoride catalyst systems, does not cause cathodic low current density etching. HP HAVACHROME – NFS exhibits very shiny, bright and smooth surfaces. The microhardness of the deposit shows values in the 1,000 KHN100 range, with a micro-cracked count greater than 1,000 cracks per linear inch providing superior corrosion and wear resistance. HP HAVACHROME – NFS is maintained by additions of the NFS product (or can be used as a separate liquid NFS-C catalyst in combination with Chromic / Sulfuric Acid) and be regulated with standard pretreatment cycles, anodes and equipment etc. BASIC OPERATING PARAMETERS: Chromic Acid Sulfate radical Ratio Temperature Cathode Current Density Range Anode Current Density Plating Rates (approximate) 32.0 oz/gal (240 g/l) 0.36oz/gal (2.70 g/l) 75 – 120 : 1 130oF – 140oF (55oC – 60oC) 2 – 10 ASI (30 – 154 ASD) 1 – 5 ASI (15 – 77 ASD) 2 ASI 60oC 1.3 mil/hr 4 ASI 60oC 2.8 mil/hr 6 ASI 60oC 4.5 mil/hr BATH CONVERSION / NEW MAKE-UP: Existing Chromium Solution Conversion Most chromium plating solution can be converted to the HP HAVACHROME – NFS. An analysis of the impurities must be done to determine the level of metallic contamination prior to conversion. Fluoride type of systems may not readily be converted to the HP HAVACHROME – NFS system. New Plating Solution Make-up Add DI water to ½ the working volume and for each 100 gallons (380 liters) of plating solution add 3 gallons HP HAVACHROME – NFL-C. Haviland Products Co. Page 1 of 3 Revised March 16, 2006 Approved: Graham M. Torr, CEF3 Technical Service Mgr. 421 Ann St. N.W. Grand Rapids, MI 49504-2075 (616) 361-6691 Fax (616) 361-9772 HP HAVACHROME - NFS Page 2 of 3 BATH CONVERSION / NEW MAKE-UP (Cont.): Add D.I. water to desired operating level and heat the solution to 140 oF (60oC). At this time analyze the plating solution for Sulfate. Add Sulphuric Acid to bring the Sulfate content to 0.33oz/USG (2.5 g/l). Electrolyze the plating solution for 5 hours to form an equilibrium with all of the components. SOLUTION MAINTENANCE HP HAVACHROME - NFS should be added based on Chromium content analysis, with additions of Sulfuric Acid made based on Sulfate analysis. HP HAVACHROME – NFS-C maintenance should be based on additions of the product at approx. 180 grams per 100lbs Chromic Acid. (Adjustments should be made based on recommendations from your Haviland Products Company representative, based on HPC lab analysis.) CONTAMINATION: Impurities that affect all hard chromium plating solutions will affect the performance of the HP HAVACHROME - NFS process. An excess of metallic contamination and trivalent chromium within solution act to reduce conductivity and wherever thick deposits are required, may contribute to roughness and pitting. Metallic concentration beginning in excess of 7500 ppm and Trivalent Chromium in excess of 3.0% are normally detrimental to process integrity. Trivalent Chromium may be re-oxidized by high current density dummy plate (see your Haviland Products Company representative for details). POWER SUPPLY: Low ripple power supplies are extremely important to assure overall performance and quality. Less than 5% ripple is recommended. Outputs of 9-15 volts D.C. corresponding to the appropriate amperage should be used. ANODES: Typical 7.0% Tin : 93.0% Lead (or Antimony : Lead) anodes may be used. Auxiliary or conforming anodes should also be made of tin or antimony-lead alloys. SOLUTION ANALYSIS: Analysis of the operating solution should be done on a routine bases. The chromic acid content of the solution can be checked via Baume’ method or wet analytical chemical methods. A standard chromic acid Baume’ scale may be used. (Keep in mind the temperature, Sulfuric Acid content and metallic contamination is important when reading the scale.) HP HAVACHROME – NFS Catalyst content within solution may be analyzed by sample submission to Haviland Products Company. HP HAVACHROME - NFS Page 3 of 3 SAFETY AND HANDLING: HP HAVACHROME – NFS compounds and the actual plating bath contain Chromic Acid that can cause severe burns. Avoid contact with eyes, skin, and clothing. Do not inhale or swallow. Eye contact can cause severe burns or loss of sight. Use with adequate ventilation and proper protective equipment. Rubber gloves and chemical safety glasses are recommended safety equipment including NIOSH/MSHA approved respirators should be used, as necessary. Do not eat or drink while handling this product, and wash thoroughly after handling these materials. Consult the individual Material Safety Data Sheets (MSDS) of the HP HAVACHROME – NFS system for complete information. NON-WARRANTY: The data contained in this bulletin is believed by HAVILAND PRODUCTS COMPANY to be accurate, true and complete. Since however, final methods of use of these products are in the hands of the customer and beyond our control, we cannot guarantee that the customer will obtain the results described in this bulletin. Nor can we assume any responsibility for the use of this product by the customer in any process which may infringe the patents of third parties.