Part 2

advertisement

Batteries: Producing Electricity via Chemical Reactions

• A battery is a cell or series of cells that generate an electrical

current.

The Leclanché (Dry) Cell

– Batteries are the means by which we harness the electrical work of a

galvanic cell and use it productively.

• Primary Cells.

– Single-use batteries that cannot be recharged

– Cell reaction is not reversible.

– The most prevalent type is the alkaline battery.

• Secondary Cells.

– Cell reaction can be reversed by passing electricity through the cell

(charging).

– Nickel-cadmium or “ni-cad” batteries are an example

• Flow Batteries and Fuel Cells.

– Materials pass through the battery which converts chemical energy to

electric energy.

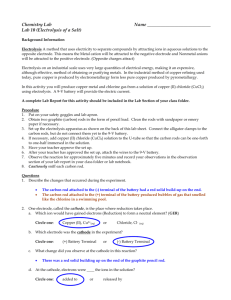

Dry Cell

Alkaline Dry Cell

2MnO2(s) + Zn(s) Mn2O3(s) + ZnO(s)

Zn(s) → Zn2+(aq) + 2 e-

Oxidation:

Reduction:

2 MnO2(s) + H2O(l) + 2 e- → Mn2O3(s) + 2 OH-

Acid-base reaction:

NH4+ + OH- → NH3(g) + H2O(l)

Precipitation reaction: NH3 + Zn2+(aq) + Cl- → [Zn(NH3)2]Cl2(s)

Alkaline Dry Cell

Reduction:

• The chemistry of

an alkaline dry

cell battery. The

net reaction is

shown above.

– The alkaline

battery is termed

a dry cell because

the KOH

electrolyte is in

the form of a

paste or gel.

The Silver-Zinc Cell: A Button Battery

2 MnO2(s) + H2O(l) + 2 e- → Mn2O3(s) + 2 OH-

Oxidation reaction can be thought of in two steps:

Zn(s) → Zn2+(aq) + 2 eZn2+(aq) + 2 OH- → ZnO + H2O

Zn (s) + 2 OH- → ZnO + H2O + 2 e-

Zn(s),ZnO(s)|KOH(sat’d)|Ag2O(s),Ag(s)

Zn(s) + Ag2O(s) → ZnO(s) + 2 Ag(s)

Ecell = 1.8 V

1

Zinc-Mercury Battery

• Mercury batteries are another type of primary cell and are

quite small. They are used for medical devices like

pacemakers.

– Zinc is the anode.

Zn(s) + 2OH-(aq) Zn(OH)2(s) + 2e– Mercury(II) oxide is the cathode

cathode.

HgO(s) + H2O(l) + 2e- Hg(l) +2OH-(aq)

• The mercury battery (also

called a zinc-mercuric

oxide cell) has a voltage

output that is extremely

stable over long times.

Zinc-Air Battery

• Zinc-air batteries are also primary cells.

– Zinc is the anode.

Zn(s) + 2OH-(aq) Zn(OH)2(s) + 2e– Oxygen reacts at the cathode.

½ O2(g) + H2O(l) + 2e- 2OH-(aq)

• In a zinc-air battery,

one of the reactants is

oxygen from the

surrounding air. As a

result, these batteries

can offer a very

attractive energy

density.

Ni-Cd Battery

Ni-Cd Battery

• The anode for a ni-cad battery is cadmium.

Cd(s) + 2OH-(aq) Cd(OH)2(s) + 2e-

• The complex cathode reaction can be represented

as

NiO(OH)(s) + H2O(l) + e- Ni(OH)2(s) + OH-(aq)

• Important design features of a nickel-cadmium battery are shown

to the left.

Metal Hydride Battery

Nickel-MetalyHydride Battery

• Nickel-metal-hydride batteries are secondary

cells.

– The anode for a nickel-metal-hydride battery is M,

some metal or metal alloy.

MH(s) + OH-(aq) M(s) + H2O(l) + e– The complex cathode reaction can be represented as

NiO(OH)(s) + H2O(l) + e- Ni(OH)2(s) + OH-(aq)

• Nickel-metal-hydride batteries have become popular as rechargeable

cells. The design is quite similar to the Ni-Cd cell, but nickel-metalhydride cells are less prone to memory effects.

2

Lead Acid Battery

Lead-Acid Battery

• The lead-acid storage battery found in cars is a secondary

cell.

Pb(s) + HSO4

-(aq)

PbSO4(s) +

H+(aq)

Reduction:

PbO2(s) + 3 H+(aq) + HSO4-(aq) + 2 e- → PbSO4(s) + 2 H2O(l)

– The anode for a lead-acid battery is lead metal.

+2

e-

– The cathode for a lead-acid battery is lead oxide.

Oxidation:

Pb (s) + HSO4-(aq) → PbSO4(s) + H+(aq) + 2 e-

PbO2(s) + 3H+(aq) + HSO4-(aq) + 2e- PbSO4(s) + 2 H2O(l)

• The lead-acid storage

battery consists of Pb

anodes alternating

with PbO2 cathodes,

all immersed in

sulfuric acid.

Fuel Cells

• A fuel cell is a voltaic cell in which the reactants

can be supplied continuously and the products of

the cell reaction are continuously removed.

• Most common type is based on the reaction of

hydrogen and oxygen to produce water.

2H2 + O2 2H2O

– Oxygen is reduced at the cathode.

O2 + 4H+ + 4e- 2H2O

– Hydrogen is oxidized at the anode.

H2 2H+ + 2e-

PbO2(s) + Pb(s) + 2 H+(aq) + 2HSO4-(aq) → 2 PbSO4(s) + 2 H2O(l)

E°cell = E°PbO2/PbSO4 - E°PbSO4/Pb = 1.74 V – (-0.28 V) = 2.02 V

Fuel Cells

O2(g) + 2 H2O(l) + 4 e- → 4 OH-(aq)

2{H2(g) + 2 OH-(aq) → 2 H2O(l) + 2 e-}

2H2(g) + O2(g) → 2 H2O(l)

E°cell = E°O2/OH- - E°H2O/H2

= 0.401 V – (-0.828 V) = 1.229 V

Efficiency value

= ΔG°/ ΔH° = 0.83

Electrolysis

Limitations of Batteries

• Corrosion is a major cause for the loss of

performance in batteries.

– Protective plating of materials used in batteries is an

attempt to limit the performance-diminishing effects of

corrosion on batteries.

• Electrolysis is the process of passing an electric

current through an ionic solution or molten salt to

produce a chemical reaction.

ect o yt c cells

ce s are

a e divided

d v ded into

to two categories

catego es

• Electrolytic

based on the nature of the electrodes used.

– Passive electrolysis: the electrodes are chemically inert

materials that simply provide a path for electrons.

– Active electrolysis: the electrodes are part of the

electrolytic reaction.

3

Electrolysis:

Causing Non-spontaneous Reactions to Occur

Galvanic and Electrolytic Cells

Galvanic Cell:

Zn(s) + Cu2+(aq) → Zn2+(aq) + Cu(s)

E°cell = 1.10 V

El

Electolytic

l

Cell:

C ll

Zn2+(aq) + Cu(s) → Zn(s) + Cu2+(aq)

E°cell = -1.10 V

Electrolysis is forcing a current through a cell to produce a

chemical change for which the cell potential is negative.

a) A standard galvanic cell based on the spontaneous reaction

Zn(s) + Cu2+(aq) Zn2+(aq) + Cu(s)

b) A standard electrolytic cell. A power source forces the

opposite reaction: Zn2+(aq) + Cu(s) Zn(s) + Cu2+(aq)

Passive Electrolysis in Refining Aluminum

• Electrolysis provides the means to overcome the

nonspontaneous reaction to separate aluminum

from its oxide.

– The Hall-Heroult refining process uses carbon

electrodes as inert sites for passive electrolysis.

– The Hall-Heroult process

involves the

electrolytic refining of

aluminum from Al2O3 to

produce aluminum metal

and oxygen gas.

Active Electrolysis and Electroplating

• The process of depositing a thin coat of metal on another

metal by using electrolysis is electroplating.

– In some cases, the thin coating is cosmetic, or to provide some vital

functionality for the coated piece, such as corrosion resistance or

desirable conductive properties.

• Silver is plated onto electrical devices because silver is a

good conductor and resistant to corrosion.

– The solution from which silver is plated contains CN–(aq) ions,

which form a complex with Ag+. The need for uniform coatings

makes this an important step.

Active Electrolysis and Electroplating

• The object being electroplated is the cathode.

Active Electrolysis and Electroplating

– Anode

Ag(s) + 2CN-(aq) Ag(CN)2-(aq) + e– Cathode

A (CN)2-(aq)

Ag(CN)

( ) + e- Ag(s)

A ( ) + 2CN-(aq)

( )

• Opposite reactions at the anode and cathode are

common for electroplating operations.

– Silver is transferred from the anode to the cathode,

coating the cathode in a thin layer of silver.

– The zero cell potential is not critical since an external

current drives electrolysis.

• Barrel plating is often used to apply coatings to small parts.

4

Electroplating

Electrolysis and Stoichiometry

• For electroplating, it can be vitally important to

use carefully controlled amounts of materials.

– C

Controlling

t lli the

th flow

fl off electrons

l t

(current)

(

t) in

i an

electroplating operation provides a method to

accurately limit the amount of material deposited.

(a) A silver-plated teapot.

Net Equation: Ag(s)anode Ag(s)cathode

(b) Schematic of the

electroplating of a spoon

– Electroplating is often used to prevent galvanic

corrosion in an electrical apparatus in places where

different metals come into contact with one another.

Transfer of material from the anode to the cathode

Quantitative Aspects of Electrolysis

How much chemical change occurs with the flow of a given

current for a specified time?

current and time quantity of charge

Charge (C) = current (C/s) x time (s)

quantity of charge moles of electrons

1 mol e- = 96485 C

ne- = I x t

F

moles of electrons moles of analyte grams of analyte

Electrolysis Examples

1. A solution containing Cu2+(aq) is electrolyzed. The

cathode reduction half reaction is

Cu2+(aq) + 2e- Cu(s).

What mass of copper will be deposited in 1.00hr by a

current of 1.5A?

2. A current of 25.5 A is used in the synthesis of MnO2(s) by

Mn2+(aq) + 2H2O MnO2(s) +2H+(aq) + H2(g)

If the electrolysis is 85% efficient, how long would it take

to produce 1.000 kg MnO2(s)

Calculations in Electrolysis

• A knowledge of current, how long the current

flows, stoichiometry, and the number of electrons

required to reduce a metal cation are used to

answer the following questions.

questions

– How much material is plated given a specific current

for an allotted time or electrical energy expenditure?

– How long must a given current to pass through the cell

to yield a desired mass of plated material?

Corrosion

• Oxidation of metals

– Metals tend to be easily oxidized

– most metals have standard reduction potentials that are

less than oxygen

• 00.40

40 V in basic solutions

• 1.23 V in acidic solutions

– The oxidation of most metal by O2 will have a positive

Ecell, so they will spontaneously occur

– Some metals, such as copper, gold, silver and platinum,

are relatively difficult to oxidize. These are often called

noble metals.

5

Corrosion: Unwanted Galvanic Cells

The Electrochemical Corrosion of Iron.

In neutral solution:

O2(g) + 2 H2O(l) + 4 e- → 4 OH-(aq)

2 Fe(s) → 2 Fe2+(aq) + 4 e-

EO2/OH- = 0.40 V

EFe/Fe2+ = 0.44 V

2 Fe(s) + O2(g) + 2 H2O(l) → 2 Fe2+(aq) + 4 OH-(aq)

Ecell = 0.84 V

In acidic solution:

O2(g) + 4 H+(aq) + 4 e- → 4 H2O (aq) EO2/OH- = 1.23 V

Corrosion Prevention

• The following observations can be used to reduce

corrosion in a number of ways.

Coatings

• Applying a protective coating to a material is the most

common way of protecting against corrosion.

– A coating can be applied with electroplating or painting.

– The coating protects the underlying material from exposure to water

and oxygen.

– Corrosion is a pervasive reaction, with a large, negative

free energy change.

– It is possible to predict what materials will corrode and

use this information to protect a material such as iron.

• Rust inhibitors can be added to paint to further inhibit

corrosion.

– Many of the common inhibitors contain the following ions:

phosphate, borosilicate, chromate, or phosphosilicate.

– All of these ions, as part of a paint coating, form compounds with

oxidized iron that inhibit further rust formation.

– This process is called passivation.

– Some materials, like aluminum, corrode readily, but the

product, in this case Al2O3, forms a protective layer that

eliminates further corrosion.

Cathodic Protection

Cathodic Protection

• Some materials are more easily oxidized than iron,

which provides a way to construct galvanic

corrosion conditions intended to protect the iron.

– Mg has a reduction potential more negative than Fe.

– When combined, Mg will oxidize and Fe will be

reduced.

• Magnesium can be used to prevent iron corrosion.

– The piece of magnesium is called a sacrificial anode.

– Connecting magnesium to iron forces iron to be the

cathode, preventing iron from oxidizing.

– This process is called cathodic protection.

– The sacrificial anode must be replaced periodically to

be effective.

•

Sacrificial anodes are one effective method of corrosion prevention.

The anode is preferentially oxidized relative to the protected metal.

6

Corrosion Protection

Summary Examples

1.

Consider an aluminum-air battery

a) The Al3+ produced at the anode is obtained as the

complex ion [Al(OH)4]-. Write equations for the

oxidation and reduction half-reactions and the net

reaction that occur in the battery.

b) The E

E°cell of the aluminum-air

aluminum air cell is +2.73

+2 73 V.

V What

is the value of the standard reduction potential of the

reaction: [Al(OH)4] + 3e Al(s) + 4OH

c) Given that G°f[OH-]= -157kJ/mol and

G°f[H2O(l)]= -237.2 kJ/mol,

What is G°f [Al(OH)4]-?

d) What mass of Al is consumed if 10.0A of electric

current is drawn from the battery for 4.00 hr.

Al-Air Batteries

Summary Examples

2. Two electrochemical cells at 25°C are connected

as shown

Cell A

┌─Zn(s)|Zn2+(0.85 M)║Cu2+(1.10 M)|Cu(s) ┐

│

│

2 (1.05 M)║Cu

2+

2 (0.75 M)|Cu(s) ┘

└

└─Zn(s)|Zn

║ 2+

Cell B

4 Al(s) + 3 O2(g) + 6 H2O(l) + 4 OH- → 4 [Al(OH)4]-(aq)

a) Do the electrons flow in the clockwise or counter

clockwise direction?

b) What are the ion concentrations in the half-cells at the

point at which the current stops flowing.

7