Solutions in Action

Trepko Group

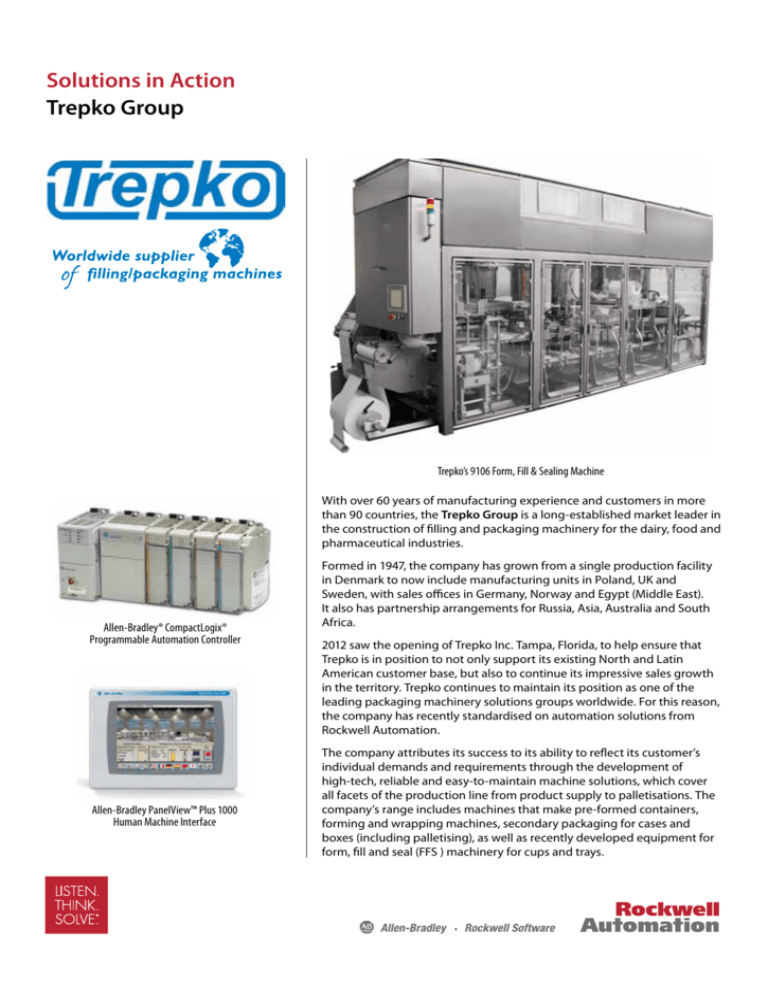

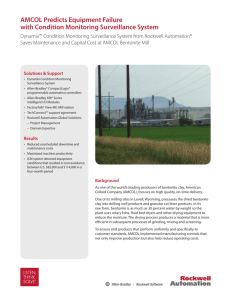

Trepko’s 9106 Form, Fill & Sealing Machine

With over 60 years of manufacturing experience and customers in more

than 90 countries, the Trepko Group is a long-established market leader in

the construction of filling and packaging machinery for the dairy, food and

pharmaceutical industries.

Allen-Bradley® CompactLogix®

Programmable Automation Controller

Allen-Bradley PanelView™ Plus 1000

Human Machine Interface

Formed in 1947, the company has grown from a single production facility

in Denmark to now include manufacturing units in Poland, UK and

Sweden, with sales offices in Germany, Norway and Egypt (Middle East).

It also has partnership arrangements for Russia, Asia, Australia and South

Africa.

2012 saw the opening of Trepko Inc. Tampa, Florida, to help ensure that

Trepko is in position to not only support its existing North and Latin

American customer base, but also to continue its impressive sales growth

in the territory. Trepko continues to maintain its position as one of the

leading packaging machinery solutions groups worldwide. For this reason,

the company has recently standardised on automation solutions from

Rockwell Automation.

The company attributes its success to its ability to reflect its customer’s

individual demands and requirements through the development of

high-tech, reliable and easy-to-maintain machine solutions, which cover

all facets of the production line from product supply to palletisations. The

company’s range includes machines that make pre-formed containers,

forming and wrapping machines, secondary packaging for cases and

boxes (including palletising), as well as recently developed equipment for

form, fill and seal (FFS ) machinery for cups and trays.

“Rockwell Automation worked hard to secure the Trepko

account. We understand the importance of working with a

component supplier that is well recognised in the market

place,” said Hansen.

“It is also important on a global stage that the component

suppliers included within the Trepko equipment solutions

have adequate support structures in place and that this

service is available for end users – clearly this is a criteria that

Rockwell Automation more than meets,” said Hansen.

The latest 822 brick wrapping machine from Trepko will produce up to 250 bricks

per minute

Examples include the 9106 Form, Fill & Seal Machine, which

is capable of forming and filling 9,000 cups per hour. The

9106 features a compact design, which utilises the very latest

forming and cutting technology. Together with a unique

hygienic frame design, this machine is the perfect solution

for any producer, large or small.

Trepko also continue to push the development boundaries

with its brick forming range of equipment, the 800 series.

The latest 822 machine can produce up to 250 bricks per

minute and is designed with the most stringent hygienic

requirements in mind, which makes it one of the cleanest

machines in the market place.

All of the equipment has one thing in common, AllenBradley® programmable automation controllers (PACs),

Allen-Bradley PanelView™ HMIs and Allen-Bradley Kinetix®

servo drives and motors.

According to Jesper Bjorn Hansen, Trepko Group CEO:

“We listen to our customer’s demands, that is why we

have heavily invested in development, both in terms of

progressing our mechanical design to improve our machines

capabilities, efficiency performance and hygienic standards,

and also working with an automation partner that can

support us through this process.

For more information, contact:

Trepko Denmark, Group Head Office

Phone: +45 43 99 22 44

E-mail: info@trepko.com

www.trepko.com

Listen. Think. Solve., Allen-Bradley, ControlLogix, CompactLogix, Kinetix and PanelView are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Publication OEM-AP304A-EN-P – April 2014

Copyright © 2014 Rockwell Automation, Inc. All Rights Reserved. Printed in the EU.