AMCOL Predicts Equipment Failure

with Condition Monitoring Surveillance System

Dynamix™ Condition Monitoring Surveillance System from Rockwell Automation®

Saves Maintenance and Capital Cost at AMCOL Bentonite Mill

Solutions & Support

• Dynamix Condition Monitoring

Surveillance System

• Allen-Bradley® CompactLogix®

programmable automation controllers

• Allen-Bradley XM® Series

Intelligent I/O Modules

• FactoryTalk® View ME HMI station

• TechConnectsm support agreement

• Rockwell Automation Global Solutions

– Project Management

– Domain Expertise

Results

• Reduced unscheduled downtime and

maintenance costs

• Maximized machine productivity

• ICM system detected equipment

conditions that resulted in cost avoidance

between U.S. $85,000 and $114,000 in a

four-month period

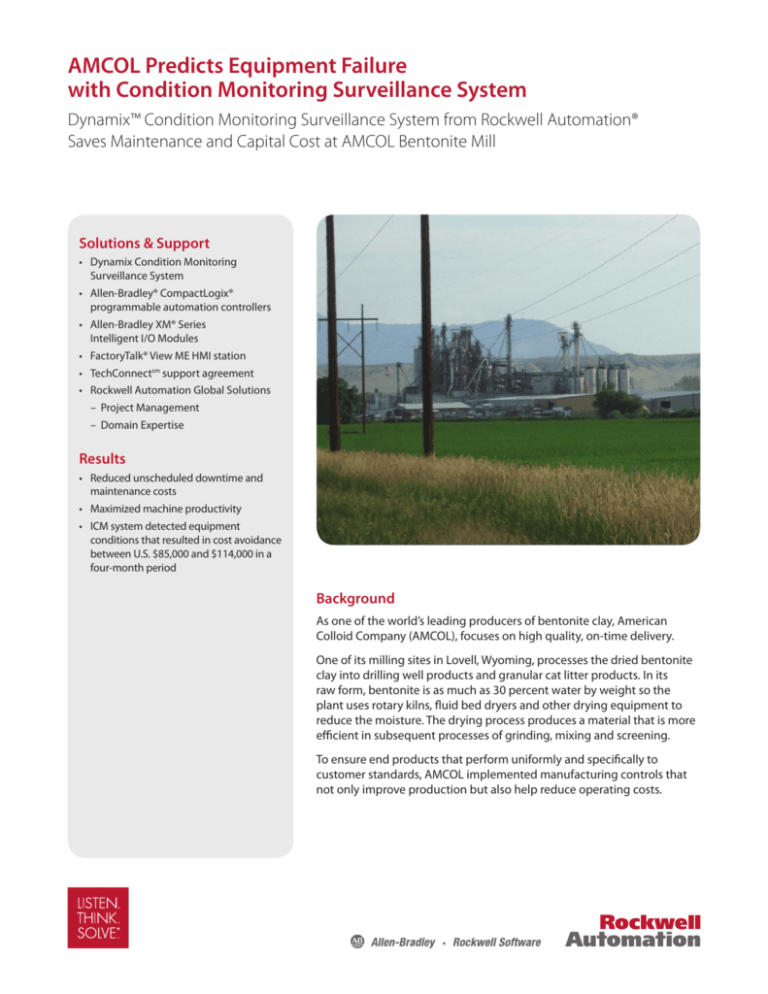

Background

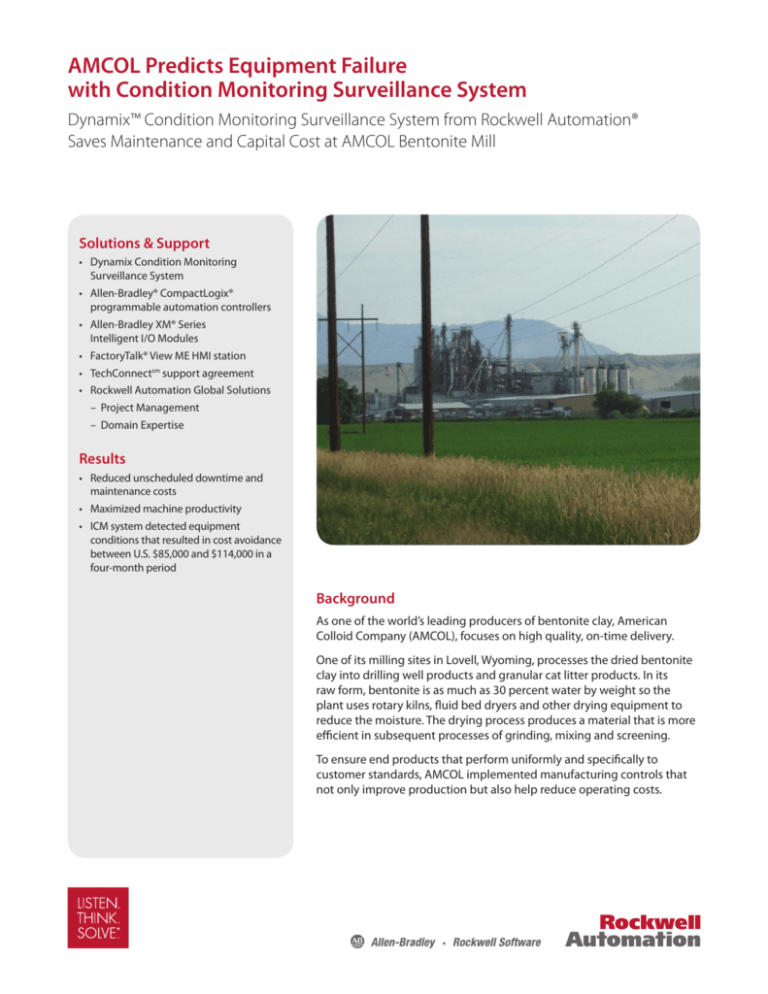

As one of the world’s leading producers of bentonite clay, American

Colloid Company (AMCOL), focuses on high quality, on-time delivery.

One of its milling sites in Lovell, Wyoming, processes the dried bentonite

clay into drilling well products and granular cat litter products. In its

raw form, bentonite is as much as 30 percent water by weight so the

plant uses rotary kilns, fluid bed dryers and other drying equipment to

reduce the moisture. The drying process produces a material that is more

efficient in subsequent processes of grinding, mixing and screening.

To ensure end products that perform uniformly and specifically to

customer standards, AMCOL implemented manufacturing controls that

not only improve production but also help reduce operating costs.

Challenge

The Raymond mills at the Lovell plant run a continuous

manufacturing operation with multiple pieces of rotating

equipment, each with the potential to break down and

halt production. If drying and milling stop so do

customer shipments.

“The plant was losing a lot of motors in the milling

process,” says David Wilkerson, Electrical and

Instrumentation Supervisor at the AMCOL Lovell plant,

“about two critical motors a year.”

The electrical and mechanical departments struggled to

identify root causes of the issue. Worn bearings and belts

went undetected, resulting in damage to motor bearings

and windings.

As part of AMCOL’s reliability initiative, the plant

contracted a third-party service provider on a monthly

basis to measure and analyze the vibration levels to

help diagnose equipment issues. However, this method

did not generate timely data, missed critical faults

between monthly intervals and did not collect data on

equipment that was not running; all of which are critical

for scheduling planned maintenance work. In the AMCOL

environment, equipment degradation can occur suddenly

and quickly ramp up to a catastrophic failure.

Solution

In the AMCOL environment, equipment

degradation can occur suddenly and

quickly ramp up to a catastrophic failure.

AMCOL’s goal was to prevent motor damage before it

happened and to reduce unplanned downtime from

equipment failures by obtaining timely and actionable

information on the equipment condition. The plant

wanted a cost-effective solution that would integrate

with their existing system architecture and have a quick

payback period.

AMCOL turned to its long-time Allen-Bradley authorized

distributor, Border States Electric, in Billings, Mont., to

help find a viable solution. Border States recommended a

cost-effective, timely and actionable Dynamix Condition

Monitoring Surveillance System with project delivery from

Rockwell Automation.

Condition monitoring is an effective method for

improving Overall Equipment Effectiveness (OEE). The

Dynamix Condition Monitoring Surveillance system helps

to protect critical assets, eliminate collateral damage and

reduce maintenance, repair, and operating (MRO) costs

through the automatic measurement and diagnosis of

machinery health and performance conditions.

The Dynamix Condition Monitoring Surveillance

System is a service and solutions offering from

Rockwell Automation’s Global Solutions team.

The system integrates appropriate Allen-Bradley XM Series

measurement modules, Logix controllers and FactoryTalk

visualization products. The solution also includes all of

the necessary controller logic and display development,

tailored to the customer’s specific needs, along with

complete system configuration and installation services

and support. While customized for each application the

solution leverages proven add-on instructions

and templates built on industry standard logic and

alarm methods. The solution designed for AMCOL was

a multiplexed system using an Allen-Bradley XM122

module, ideal for detecting rolling element bearing faults,

linked to an Allen-Bradley CompactLogix L35E controller

and a FactoryTalk View ME HMI station.

The Dynamix solution provides early warning of

impending failures and continually assesses the condition

of the plant’s equipment to help prevent problems

before they occur. XM modules provide the core vibration

analysis by converting raw time waveforms into a

frequency spectrum. Up to four different frequency bands

can be programmed for each input to give early warning

notification of specific machinery issues.

Utilizing the surveillance and alarming add-on option to

AMCOL’s TechConnectsm support agreement, Wilkerson

monitors plant asset data on a daily basis and schedules

maintenance work orders accordingly.

“The new system gives us two to three

months warning of impending failures

which allows us time to schedule

maintenance,” says Wilkerson.

“The new system gives us two to three months warning

of impending failures which allows us time to schedule

maintenance,” says Wilkerson. “Having the system issue

advisories in plain English was perfect since we don’t have

vibration specialists on staff.”

The third party provider continues to measure

vibration data via scheduled walk-arounds but is now

also hired to diagnose suspected problems reported

by the Dynamix system.

The Rockwell Automation Global Solutions team delivered

a complete solution by providing the domain expertise

to recommend the appropriate condition monitoring

solution, effective project planning, engineering,

installation, system configuration and validation. Using

a collaborative approach, the Global Solutions team

configured the system to capture data from the critical

areas of the equipment and the third-party provider

monitors the system-generated reports to identify

root causes.

Results

Following implementation of the condition monitoring

system in November 2009, AMCOL was able to identify a

variety of potential equipment failures.

As of April 2011, Wilkerson said, “We have not had an

unexpected motor failure since we’ve deployed the

Dynamix Condition Monitoring Surveillance system.”

From specific savings, such as not needing to rewind

or replace motors, to general savings such as reducing

unscheduled downtime and maintenance costs,

integrated condition monitoring helps AMCOL maximize

machine productivity by integrating systems and

processes, and using multiple technologies to monitor

machine performance.

“The beauty of this program is that it warns you if

something is unbalanced, loose, or if spike energy is

high which usually points to a lubrication problem,” says

Wilkerson. “The system helps us identify the root cause

of each issue quickly.” Together, the system hardware and

software enables capturing this type of data.

“The online monitoring system has also been a key tool

for detecting loose belts or a soft foot on our Raymond

mill fans and drives,” says Wilkerson. “We have had three

separate loose belt situations in the months of January

and February. This can lead to damage to sheaves, belts,

and even excessive damage to bearings.”

The average cost of replacement is $900 for fan bearings,

$1,600 for motor bearings, $1,650 to replace sheaves and

$960 to replace a belt. AMCOL was able to tighten the

belts on three of the motor mill fans at no cost.

The purchase and installation of the Dynamix Condition

Monitoring Surveillance System has been a key asset to

avoiding expensive failures. Over a three month period,

the system detected six key equipment conditions that

have resulted in a cost avoidance of between $85,000

and $114,000.

AMCOL realized a payback on the ICM system in less than

4 months.

In one example, the vibration monitoring system indicated

an increasing trend of high vibration on the #4 mill. Upon

further inspection, AMCOL discovered a large crack in the

spider – the mill component that suspends mill journals

and mill rolls. Had the crack evolved into a break, it would

have resulted in a catastrophic failure of the mill, and a

$90,000 mill re-build. Instead, AMCOL replaced the spider

for $14,000, for potential savings of $76,000.

“We’ve proven the concept and our central maintenance

group for western mining is considering deploying the

solution at other sites,” says Wilkerson.

The results mentioned above are specific to AMCOL’s use of

Rockwell Automation products in conjunction with other products.

Specific results may vary for other customers.

Advanced detection and notification of several motors

using continuous motor trending meant AMCOL was able

to replace motor bearings at a cost of $1,700, rather than

motor replacement at approximately $13,000 or motor

re-build at $5,000.

Allen-Bradley, CompactLogix, Dynamix, FactoryTalk, Rockwell Automation, TechConnect and XM are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Publication MFGVP-AP007A-EN-P – July 2011

Copyright © 2011 Rockwell Automation, Inc. All Rights Reserved. Printed in USA.