The effects of the composition of growth medium and fermentation

advertisement

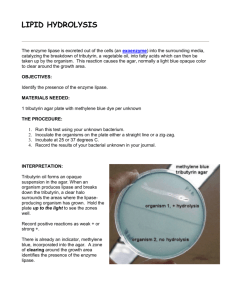

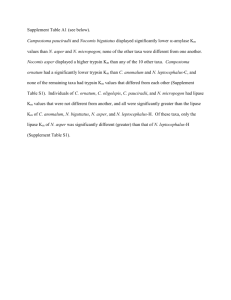

Turk J Biol 35 (2011) 35-44 © TÜBİTAK doi:10.3906/biy-0902-14 The effects of the composition of growth medium and fermentation conditions on the production of lipase by R. delemar Ünsal AÇIKEL1,*, Mehtap ERŞAN1, Yeşim SAĞ AÇIKEL2 1 Department of Chemical Engineering, Cumhuriyet University, 58140, Campus, Sivas - TURKEY 2Department of Chemical Engineering, Hacettepe University, 06800 Beytepe, Ankara - TURKEY Received: 10.02.2009 Abstract: Lipases (triacylglycerol hydrolases) are hydrolytic enzymes that can catalyze the hydrolysis of the ester bond of long-chain acylglycerols at the oil-water interface. The present study investigated the effects of inducers, surface-active materials, activators, and inhibitors in the fermentation medium on lipase activity in Rhizopus delemar. In the presence of certain commercial oils and tributyrin as an inducer, lipase activity decreased in the order of sunflower oil > soybean oil > hazelnut oil > corn oil > tributyrin > olive oil. In addition, the effects of the stirring and aeration rates on lipase activity were investigated. To investigate the effect of surface-active materials on lipase activity 2 different surface-active materials, Tween-80 and rhamnolipid (biosurfactant), were used as comparatives with tributyrin. Maximum lipase activity was observed in the fermentation medium containing Tween-80 as both an inducer and surface-active material. The combined effects of molasses and sucrose on lipase production by R. delemar were also investigated. Lipase activity in the presence of activators decreased in the order of NaCl > KCl > CaCl2 > MgCl2 > gum arabic > EDTA, and maximum lipase activity of 964.55 U/L was obtained. The presence of heavy metal ions in the fermentation media severely inhibited 2+ 2+ 2+ 2+ lipase activity. Lipase activity in the presence of heavy metal ions decreased in the order of Fe > Mn > Co > Ni . Key words: Lipase production, R. delemar, fermentation, batch stirred reactor Üreme ortamı bileşimi ve fermentasyon koşullarının R. delemar’ın lipaz üretimi üzerine etkileri Özet: Lipazlar (triaçilgliserol hidrolazlar), yağ-su arayüzeyinde, uzun zincirli açilgliserollerin, ester bağlarının hidrolizini katalizleyen hidrolitik enzimlerdir. Bu çalışmada, Rhizopus delemar’ın lipaz aktivitesi üzerine, fermentasyon ortamındaki indükleyicilerin, yüzey aktif maddelerin, aktivatörler ve inhibitörlerin etkileri araştırıldı. İndükleyici olarak, belirli ticari yağlar ve tribütirinin varlığında, elde edilen lipaz aktiviteleri, sırasıyla ayçiçeği yağı > soya yağı > fındık yağı > mısır yağı > tribütirin > zeytin yağı olarak azalmaktadır. Buna ek olarak, karıştırma hızı ve havalandırma hızının lipaz aktivitesi üzerine etkileri araştırıldı. Yüzey aktif maddelerin lipaz aktivitesine etkisinin incelenmesi için, iki farklı yüzey aktif madde, Tween-80 ve rhamnolipid (biyosurfaktan), tribütirin ile karşılaştırmalı olarak kullanılmıştır. Maksimum lipaz aktivitesi, hem bir indükleyici hem de bir yüzey aktif madde olarak Tween-80 içeren fermantasyon ortamında elde edilmiştir. R. delemar’ la lipaz üretimi üzerine, melas ve sakkarozun birleştirilmiş etkileri de araştırılmıştır. Aktivatörlerin varlığında elde edilen lipaz aktiviteleri, sırasıyla NaCl > KCl > CaCl2 > MgCl2 > arap zamkı > EDTA olarak azalmış ve maksimum lipaz aktivitesi 964,55 U/L olarak bulunmuştur. Fermantasyon ortamında bulunan ağır metal iyonları lipaz +2 +2 aktivitesini şiddetli bir şekilde düşürmüştür. Ağır metal iyonlarının varlığında lipaz aktivitesi sırasıyla Fe >Mn +2 +2 >Co >Ni olarak azalmıştır. Anahtar sözcükler: Lipaz üretimi, R. delemar, fermentasyon, kesikli karıştırmalı reaktör 35 The effects of the composition of growth medium and fermentation conditions on the production of lipase by R. delemar Introduction Lipases (triacylglycerol acyl hydrolases) are one of the most important classes of industrial enzymes. Lipases are biological catalysts that hydrolyze triglycerides to di- and monoglycerides, glycerol, and fatty acids, and under certain conditions catalyze the reverse reaction, forming glycerides from glycerol and fatty acids (1). Worldwide, there is considerable interest in the use of commercially available lipases for the hydrolysis of oils, synthesis of esters, interesterification of oils and fats, synthesis of peptides, and resolution of racemic mixtures to produce optically active compounds (2-6). This interest stems from such characteristic lipase properties as substrate specificity and stereospecificity, and their ability to catalyze heterogeneous reactions at the interface of watersoluble and water-insoluble systems (7-9). Microbial lipases have a broad spectrum of industrial application, as they are more stable and suitable for genetic manipulation than plant and animal lipases, and they can be obtained cheaply. Microbial lipases are used in the food industry (10), detergents (11), pharmaceuticals (12), cosmetics (13), leather processing (6), the paper industry (5), biosensors (14), biodegradation of polymers (15), biodiesel-fuel production (16), the manufacturing of fine chemicals (in particular, pesticides) (17), and waste management (18,19). The lipase from Rhizopus delemar is currently the subject of intensive research and industrial interest because it produces at least 3 extracellular lipases, each of which exhibits a strong preference for the hydrolysis of ester bonds at the sn-1 and sn-3 positions of triacylglycerol. Partially purified mixtures of these enzymes are used in a variety of reactions, including ester and glyceride synthesis, glyceride restructuring, and the exchange of the acyl groups of phospholipids (20-22). Regulation of the synthesis of R. delemar lipase is complex, and the effects of fermentation conditions, such as pH, temperature, inoculum level, carbon and nitrogen sources, inducers, and activators, can be major (23). Data on the fermentation process are critical to the search for optimal operation conditions for enzyme production (24). present study examined this process in relation to the composition of the growth medium, including selection of the optimum inducer or surfactant, and fermentation conditions, such as the optimum quantity of inducer and surfactants, and the stirring and aeration rates. Materials and methods Microorganism and growth medium R. delemar was obtained from the US Department of Agriculture Culture Collection (NRRL 2872). R. delemar was grown in an agitated liquid-basal medium that contained the following ingredients (g L-1): molasses sucrose: 1; K2HPO4: 0.5; KH2PO4: 0.5; MgSO4.7H2O: 0.2; yeast extract: 2. For the experiments performed with molasses sucrose the growth medium included molasses diluted to the desired sucrose concentration as the main carbon source. Molasses was obtained from Ankara Sugar Factory (Turkey). Molasses is a co-product of sugar production from sugar beet, and is defined as the runoff syrup from the final stage of crystallization. Sugar beet molasses is a solution of sugar, and organic and inorganic matter in water, with a solid substance of 84% (w/w). Total sugars (mainly sucrose) constitute approximately 50% (w/w) of molasses, ash 11% (w/w), and total nitrogen-containing compounds (mainly betaine) 7%-8% (w/w) (Table). Molasses also contains biotin, and to a lesser extent invert sugar and raffinose, trace elements such as K+, Na+, Ca2+, Mg2+, Fe2+, Al+, Cl-, SO4-, PO4-, and NO3-, metal oxides, and acid anhydrates. Table. Organic sugar and N2 content of molasses obtained from Ankara Sugar Factory. Sa Pb Qc Invert sugar Betain Total N2 Raffinose Density a The optimum conditions for lipase production by R. delemar have yet to be described in full detail. The 36 % 83.92 % 50.03 % 59.62 % 0.406-0.500 % 5.0 -6.0 % 2.0 % 0.8 – 1.0 1.3 Amount of solid substance Polarization c P/S b Ü. AÇIKEL, M. ERŞAN, Y. SAĞ AÇIKEL Analytical procedure Dry weight of the biomass was determined by filtering the sample medium over filter paper. The filters were dried at 60 °C until constant weight was achieved. For lipase activity measurement the spectrophotometric method of p-nitro-phenylpalmitate (pNPP) was used as follows: solution A contained pNPP dissolved in propan-2-ol; solution B contained gum arabic and Triton X-100 dissolved in distilled water, and the pH of the solution was adjusted to 8.0. The substrate solution was prepared by adding solution A to solution B dropwise under intensive stirring. The pH of the substrate solution was adjusted to 8.5 using Tris buffer. For lipase activity measurement an enzyme sample was added to the substrate solution. The reaction mixture was incubated at 37 °C for 30 min in a rotary shaker operating at 150 rpm. The rate of p-nitrophenol liberation was measured at 410 nm using a spectrophotometer. One enzyme unit (U) of lipase activity was defined as the amount of enzyme needed to liberate 1 μmol of pNP per minute at the conditions described for each assay system (25). production, and facilitate its purification and utilization. The production of microbial lipases is generally induced by fat-related carbon sources. The effect on the lipase enzyme activity of R. delemar of certain commercial oils and tributyrin as inducers was investigated in fermentation media containing molasses sucrose as the main carbon source. The oils investigated included sunflower oil, soybean oil, hazelnut oil, olive oil, and corn oil. Inducers were added at 0.5% (v/v) to the fermentation media. Maximum enzyme activity was observed in the fermentation medium containing sunflower oil (Figure 1). The inclusion of sunflower oil in the fermentation medium resulted in a significant increase in lipase production. In the presence of sunflower oil maximum lipase activity was 93.07 U/L, which was approximately 19.7-fold greater than that in the absence of an inducer. The production of extracellular lipase increased steadily with cultivation time. Maximal enzyme activity was reached after 5 days of culturing. Most of the lipase was produced by R. delemar during the late exponential phase of growth. When other commercial oils were used together with molasses, a significant increase in lipase activity was also observed. Lipase activity decreased in the order of sunflower oil > soybean oil > hazelnut oil > corn oil > tributyrin > olive oil. R. delemar lipase exhibits a strong preference for the hydrolysis of ester bonds at the sn-1 and sn-3 positions of triacylglycerol. 100 60 40 20 0 Results and discussion The effect on lipase activity of certain commercial oils and tributyrin as inducers The addition of lipase inducers to the culture medium of microorganisms can enhance lipase Sunflower oil Soybean oil Hazelnut oil Olive oil Corn oil Tween- 80 Rhamnolipid Tributyrin 80 Activity (U/L) Inducers or surfactants were added to the culture broth in concentrations of 0.5%-4% (v/v). Inoculation was carried out aseptically with the cells at the end of the lag phase. The optimum inoculum ratio (volume of inoculum/production volume of the bioreactor) was determined to be 5/1000, and all inoculum was added to the fermentation media at this ratio. Flasks (250 mL) containing 100 mL of the growth liquid medium were incubated on a rotary shaker at 100 rpm at 30 °C. The pH of the medium was initially adjusted to 8.0, determined as optimum for lipase production in our previous studies, and allowed to follow its natural course. In order to investigate the effect of the stirring and aeration rates, lipase fermentation was performed in a batch-baffled and magnetically stirred reactor. The working volume of the reactor was 100 mL. 0 2 4 6 8 Time (Day) 10 12 Figure 1. Time course of lipase activity in fermentation media containing various oils, surfactants, and tributyrin as inducer (pH = 8.0; temperature = 30 °C; concentration of molasses sucrose = 1 g/L, concentration of inducer = 0.5% (v/v)). 37 With this marked positional selectivity, R. delemar lipase exhibits little selectivity for hydrolysis of substrates with different fatty acid moieties. Studies on triglyceride mixtures show that tributyrin is the least preferred substrate (22). Li et al. reported that oleic acid was the best inducer for enhancing the production of Rhizopus arrhizus lipase, and the highest lipase activity obtained was 3.62-fold greater than that before oleic acid feeding (26). Elibol and Özer reported that in the presence of corn oil lipase activity of immobilized R. arrhizus was approximately 2.5-fold greater than that in the absence of an inducer (27). Rodriguez et al. used different triglycerides (olive, sunflower, corn, peanut, walnut, and grape seed oils) for Rhizopus homothallicus lipase production and interestingly observed that this fungal strain was able to produce similarly high lipase activity with each oil (28). As can be seen, reported results concerning the best inducer for the production enhancement of Rhizopus sp. lipase vary. The results obtained in the present study are in agreement with those for R. delemar lipase production reported by Espinosa et al. (29). Different oils were tested as the sole carbon source. Sunflower oil yielded the highest enzyme production, and tributyrin and olive oil yields did not significantly differ, and were generally low. The effect of the sunflower oil concentration on maximum lipase activity was also investigated at 4 different concentrations, varying from 0.5%-4% (v/v). Lipase activity decreased as the sunflower oil concentration increased; the 0.5% (v/v) sunflower oil concentration was the optimum inducer concentration. Unlike lipase activity, the biomass concentration increased as the sunflower oil concentration increased up to 1% (v/v), and then the maximum biomass concentration remained an approximately constant 5.73 g dry weight/L (D.W.) (Figure 2). In the course of lipase synthesis R. delemar uses molasses sucrose as both a carbon and energy source. Molasses sucrose may be consumed to assimilate into biomass, assimilate into an extracellular product, and as energy for growth and maintenance, whereas sunflower oil is used as an inducer and/or carbon source. 38 Biomass Concentration (g D. W./L) The effects of the composition of growth medium and fermentation conditions on the production of lipase by R. delemar 8 0,5% (v/v) 1% (v/v) 2% (v/v) 4% (v/v) 6 4 2 0 0 2 4 6 Time (Day) 8 10 Figure 2. Time course of biomass concentration in fermentation media containing various concentrations of sunflower oil (pH = 8.0; temperature = 30 °C; concentration of molasses sucrose = 1 g/L). The effect of surface-active materials on lipase activity Surface-active materials either affect the permeability of the cell, increasing the secretion of lipase, or have a surfactant effect on cell-bound lipase. To investigate the effect of surface-active materials on lipase activity 2 different surface-active materials, Tween-80 and rhamnolipid (biosurfactant), were used as comparatives with tributyrin. Surface-active materials were added to the fermentation media at 0.5% (v/v). As can be seen in Figure 1, higher enzyme activity was observed in the fermentation medium containing Tween-80, as compared to media containing rhamnolipid or tributyrin. In the presence of Tween-80 maximum lipase activity was 63.68 U/L, which was approximately 13.5-fold greater than that in the absence of the surface-active material. Tween-80 seems to have a double effect on lipase activity. Tween-80 can act as an inducer and is also a surfactant. The presence of Tween-80 stimulates the release of the enzyme, increasing lipase activity recovered in the growth medium. Tween-80 can also be used as a sole carbon source in the culture medium, as it is miscible with water and does not inhibit fungal growth. Lipase synthesis was reported to be inhibited by high concentrations of oleic acid, and thus by high concentrations of olive oil (30). In the present study the lowest lipase activity (52.27 U/L) was obtained when olive oil was added to the Ü. AÇIKEL, M. ERŞAN, Y. SAĞ AÇIKEL fermentation medium. Tween-80 provides oleic acid, the intrinsic carbon source for cell growth and lipase production via a mode of controlled release; therefore, it decreases the repression of lipase synthesis. R. delemar lipase activity in the presence of surfaceactive materials decreased in the order of Tween-80 > tributyrin > rhamnolipid. The other biological surface-active material used in the present study was rhamnolipid (from the glycolipids group) produced by Pseudomonas aeruginosa. The effect of the commercial biosurfactant rhamnolipid (supplied from Jeneil Co.) as an inducer was not previously investigated. The inclusion of rhamnolipid in the fermentation medium resulted in lipase production 4.5-fold greater than that observed in the control (no surfactant added). Variation in the concentration of Tween-80 also enhanced lipase production. Maximum lipase activity (91.73 U/L) was observed when 1% (v/v) Tween-80 was added to the substrate as an additional carbon source and inducer; however, lipase activity decreased at higher Tween-80 concentrations. It was accepted that the increase in fatty acid accumulation via hydrolysis of the substrate suppressed lipase synthesis. The inclusion of 0.5% and 1% (v/v) Tween-80 in the fermentation medium resulted in an increase in biomass production (2.96 and 3.93 g dry weight/L, respectively), as compared to the control (0.55 g dry weight/L) (no surfactant added). Increasing the concentration of Tween-80 to 2% and 4 % (v/v) decreased the biomass concentration to 2.18 and 2.13 g dry weight/L, respectively. In order to overcome mass transfer limitations it is very important to study the optimum stirring rate. When stirring rates were increased from 50 to 250 rpm, lipase activity (103.12 U/L) increased as the stirring rate increased from 50-200 rpm, and then decreased as the rate increased to 250 rpm (Figure 3). Enzymes are very sensitive to mechanical force. Shear stress at higher stirring rates might disturb the intricate shape of a complex molecule to such a degree that enzyme denaturation occurs. The decrease in enzyme activity observed at the highest stirring rate tested in the present study may have been due to perturbation of the protein structure during the synthesis of lipase. The presence of air is essential for lipase production. The effect of oxygen limitation on lipase production by pellet and filamentous cultures can be significant. Oxygen can even be the limiting substrate in shake flask cultures with pellet growth. Maximum lipase activity (102.83 U/L) was obtained with a 2vvm aeration rate on the fourth day of fermentation. At the 4-vvm aeration rate high lipase activity (97.4768.80 U/L) was maintained for a longer period of time (between the 4th and 6th days of fermentation) in the culture broth. The presence of aeration increased lipase activity. A reduction in the fermentation time due to an increase in the aeration rate was noted. Moreover, enzyme activity occurred earlier and lasted longer. The effect of the stirring and aeration rates on lipase activity 50 rpm 100 rpm 150 rpm 200 rpm 250 rpm 100 Activity (U/L) Filamentous microorganisms such as molds often form microbial pellets at high biomass concentrations and in the absence of stirring the suspension culture. Moreover, the morphology of R. delemar is normally a pellet-like cake. Alternatively, filamentous cells can grow on the surface of a moist solid or fermentation liquid in the presence of insufficient stirring. The transport of both substrate and inducer to the cells inside pellets, and the release of enzyme produced inside pellets to the growth medium may be subject to diffusion limitations. This problem is the same that occurs with bacteria or yeasts entrapped/immobilized in spherical gel particles. 120 80 60 40 20 0 0 2 4 6 Time (Day) 8 10 12 Figure 3. Effect of stirring rate on lipase activity (pH = 8.0; temperature = 30 °C; concentration of molasses sucrose = 1 g/L; concentration of sunflower oil = 0.5% (v/v)). 39 The effects of the composition of growth medium and fermentation conditions on the production of lipase by R. delemar The combined effect on enzyme activity of molasses sucrose and sucrose as the carbon source Although R. delemar utilizes a variety of carbon and nitrogen sources for lipase production, molasses was chosen in the present study due to its high sucrose and other nutrient content, low cost, ready availability, and ease of storage for industrial production. As molasses is readily available as a waste material of the sugar industry, enzyme production costs can be reduced considerably when it is added to fermentation media as a source of carbon, nitrogen, and some other useful trace elements. To increase the effect of the carbon source on enzyme activity, both sucrose and molasses were added to fermentation media. To prevent the inhibition effect of the components of molasses other than sugar, such as some undesired trace elements and metal oxides, the molasses sucrose concentration should be kept at the optimum value of 1.0 g/L. The sucrose concentration was increased to 1-10 g/L in the fermentation media containing 1.0 g/L of molasses sucrose. Maximum lipase activity (92.27 U/L) was obtained in the fermentation medium containing 5 g/L of sucrose on the fourth day of fermentation (Figure 4). The inclusion of 5 g/L of sucrose in the fermentation medium resulted in lipase production that was 36.5fold greater than that obtained with the control (only sucrose at the same concentration was added) and lipase production 19.5-fold greater than that with the fermentation medium to which 1.0 g/L of molasses sucrose alone was added. The maximum biomass concentration (7.95 g dry weight/L) was obtained in the fermentation medium that contained 5.0 g/L of sucrose (Figure 4). Sucrose concentrations higher than 5.0 g/L inhibited both the enzyme activity and biomass concentration. The combined effect on enzyme activity of molasses sucrose and sucrose as carbon sources, sunflower oil as an inducer, and Tween-80 as a surface-active material Firstly, to observe the effect of sunflower oil alone sunflower oil as an inducer was added to the fermentation medium containing both molasses and sucrose. Although maximum lipase activity was observed on the 4th day of fermentation, relatively high, stable, and long-term enzyme activity was also observed between the 4th and 7th days of fermentation. In the presence of 0.5% (v/v) sunflower oil maximum lipolytic activity was 219.71 U/L, which was approximately 86.8-fold greater than that in the absence of molasses and sunflower oil, 46.4-fold greater than that in the absence of sucrose and sunflower oil, 2.36-fold greater than that in the absence of sucrose, and 2.38-fold greater than that in the absence of sunflower oil (Figure 5). The maximum 600 500 Activity (U/L) 80 7 6 60 5 1 g/L Activity 2 g/L Activity 5 g/L Activity 10 g/L Activity 1 g/L Biomass Conc. 2 g/L Biomass Conc. 5 g/L Biomass Conc. 10 g/L Biomass Conc. 40 20 0 2 4 6 Time (Day) 8 10 4 3 2 1 0 Figure 4. Effect of sucrose concentration on lipase activity and biomass concentration in fermentation media containing molasses sucrose and sucrose as main carbon sources (pH = 8.0; temperature = 30 °C; concentration of molasses sucrose = 1 g/L). 40 Activity (U/L) 8 0 Sunflower oil Tween - 80+Sunflower oil 9 Biomass Concentration (g/L) 100 400 300 200 100 0 0 2 4 6 8 Time (Day) 10 12 Figure 5. Effects of sunflower oil and combined effects of sunflower oil and Tween-80 on lipase activity in fermentation media containing molasses sucrose, and sucrose as main carbon sources (pH = 8.0; temperature = 30 °C; concentration of molasses sucrose = 1 g/L; concentration of sucrose = 5.0 g/L; concentration of sunflower oil = 0.5% (v/v), concentration of Tween-80 = 1% (v/v)). Ü. AÇIKEL, M. ERŞAN, Y. SAĞ AÇIKEL biomass concentration was 7.74 g dry weight/L at the end of the ninth day of fermentation, which was very similar to the biomass concentration obtained in the fermentation medium that contained both molasses and sucrose (Figure 6). Secondly, to stimulate the release of the enzyme, Tween-80 was also added to the fermentation medium containing molasses sucrose and sucrose as carbon sources, and sunflower oil as an inducer. The results show that lipase production was 2.30-fold greater and lipase activity was 505.42 U/L when 1% (v/v) Tween-80 was added to the medium (Figure 5); however, mycelial growth decreased 1.48-fold (5.24 g dry weight/L), as compared with the 7.74 g dry weight/L in its absence (Figure 6). The effect of activators on lipase activity A range of different activators (NaCl, KCl, CaCl2, MgCl2, gum arabic, and EDTA) was tested for their ability to support growth and enzyme production by R. delemar. For the purpose of observing the effect of the activators on lipase activity, 0.5 g/L of activator was added to the fermentation medium. Lipase activity observed in the presence of activators decreased in the order of NaCl > KCl > CaCl2 > MgCl2 > gum arabic > EDTA, and maximum lipase activity (964.55 U/L) was obtained in the presence of NaCl. R. The maximum biomass concentration (4.44 g dry weight/L) was obtained in the presence of CaCl2 in the fermentation medium. The biomass concentrations obtained in the presence of activators decreased in the order of CaCl2 > KCl > NaCl > gum arabic > MgCl2 > EDTA. The effect of heavy metal ions on lipase activity To observe the effect of heavy metal ions on lipase activity 0.1 g/L of metal ions were added to + + 2+ 2+ fermentation media. Na , K , Ca , and Mg ions enhanced R. delemar lipase activity, whereas Fe2+, Mn2+, Co2+, and Ni2+ inhibited it. Lipase activity in the presence of heavy metal ions decreased in the order of Fe > Mn > Co > Ni (Figure 8). Salts of Co2+ and Ni2+ strongly inhibited lipase activity, suggesting that they were able to alter enzyme conformation. Enzyme activity in the media containing Fe2+ (85.23 U/L) and 8 1200 KCl NaCl CaCl2 MgCl2 Gum Arabic EDTA 1000 6 Activity (U/L) Biomass Concentration (g D. W./L) 10 delemar lipase activity increased 1.91-, 1.85-, 1.83-, + + 2+ 2+ 1.76-fold, respectively, when Na , K , Ca , and Mg ions were added to the production medium (Figure 7). The enzyme required Na+, K+, Ca2+, and Mg2+ ions as cofactors for catalytic activity. Lipase activity was not affected by the metal chelator EDTA. As crude enzyme samples taken from the fermentation medium were used for the assay, EDTA might have formed complexes with other compounds present in the supernatant liquid phase, rather than with ions in the lipase. 4 Sunflower oil Tween-80+Sunflower oil 2 0 0 2 4 6 Time (Day) 8 10 Figure 6. Effects of sunflower oil and combined effects of sunflower oil and Tween-80 on biomass concentration in fermentation media containing molasses sucrose and sucrose as main carbon sources (pH = 8.0; temperature = 30 °C; concentration of molasses sucrose = 1 g/L; concentration of sucrose = 5.0 g/L; concentration of sunflower oil = 0.5% (v/v); concentration of Tween-80 = 1% (v/v)). 800 600 400 200 0 0 1 2 3 4 5 Time (Day) 6 7 8 Figure 7. Effects of activators on lipase activity (pH = 8.0; temperature = 30 °C; concentration of molasses sucrose = 1 g/L; concentration of sucrose = 5.0 g/L; concentration of sunflower oil = 0.5% (v/v); concentration of Tween-80 = 1% (v/v); concentration of activator = 0.5 g/L). 41 The effects of the composition of growth medium and fermentation conditions on the production of lipase by R. delemar 100 Mn Co Fe Ni Activity (U/L) 80 60 40 20 0 0 2 4 Time (Day) 6 8 Figure 8. Effects of inhibitors on lipase activity (pH = 8.0; temperature = 30 °C; concentration of molasses sucrose = 1 g/L; concentration of sucrose = 5.0 g/L; concentration of sunflower oil = 0.5% (v/v); concentration of Tween-80 = 1% (v/v); concentration of inhibitor = 0.1 g/L). Mn2+ (71.25 U/L) was approximately equal to the enzyme activity observed in the media containing molasses as the sole carbon source, and sunflower oil as the sole inducer or Tween-80 as the sole inducer. Depending on the concentration of heavy metal ions, enzyme activity, of course, increased or decreased. Biomass concentrations in the presence of heavy metal ions also decreased in the same order of Fe > Mn > Co > Ni. The maximum biomass concentration (5.51 g dry weight/L) occurred in the presence of Fe ions; Ni ions strongly inhibited microorganism growth and the biomass concentration decreased to 2.78 g dry weight/L. Very little information is available on lipase enzyme activity in the presence of heavy metals. Reported results concerning the effect of heavy metals on lipase activity are inconsistent. The following metal ions are known inhibitors of lipase: Ag+, Al3+, Mn2+, Sn2+, and Zn2+. Strong inhibitors are Hg2+ and Fe2+. Ca2+ is commonly known as a lipase activator. Mg2+ is also a known lipase activator, but Fe3+ and Cu2+ are commonly known as inhibitors. All these metal ions, as well as Ca2+, were reported to have an inhibitory effect on the lipase activity of Flavobacterium odoratum (31). Interestingly, it was also reported that 3 of these traditional inhibitory metal ions, Fe2+, Fe3+, and Cu2+, as well as Mg2+ enhanced F. odoratum lipase activity. The effects of metal salts on a thermostable 42 lipase from Pseudomonas sp. (KWI-56) were studied (32). The enzyme was reported to be inhibited by Cu2+, Hg2+, Sn2+, and Zn2+, but was not affected by Ca2+. Lipase from Pseudomonas aeruginosa LP602 was reported to be insensitive to many ions tested (i.e. Cd2+and Co2+, the remaining activity of the enzyme was higher than 80%), except Zn2+, which inhibited activity by 48% (18). This lipase was assumed to be stable against ions reported to inhibit other lipases (i.e. Fe3+, Fe2+, and Hg2+). While the enzyme treated with Ca2+ exhibited a slight increase in activity, the enzyme remained insensitive to Na+, Ag+, and Ni2+ ions. The enzyme also remained stable when treated with EDTA. In contrast to our results, Pseudomonas aeruginosa KKA-5 lipase activity was reported to decrease by about 20%-30% in the presence of Na+ + and K (group IA), whereas among the group IIA ions (the alkaline-earth metals) Mg2+ and Ca2+ enhanced it (33), providing results consistent with those obtained in the present study. Incubation of crude P. aeruginosa KKA-5 lipase in metals like Mn2+ from group VIIB, and Fe2+, Ni2+, and Co2+ from group VIIIB inhibited activity by 5%-15%, similarly as in the present study. Fe2+, Fe3+, Hg2+, and Cu2+ ions were reported to decrease Rhizopus oryzae lipase activity (34). The presence of –SH groups in the lipase molecule gives the enzyme intrinsic instability and causes inactivation of the enzyme via oxidation or interaction with certain heavy metal ions (35). Heavy metal ions react with –SH groups in the side groups of cysteine residues in the protein chain (36). If cysteine residue is somewhere on the protein chain, which affects the way it folds into its tertiary structure, altering this group, it could change the shape of the active site and the enzyme becomes deactivated. Conclusion The effects of different commercial oils and tributyrin were observed on the production of R. delemar lipase. In the presence of 0.5% (v/v) sunflower oil maximum lipase activity was 93.07 U/L, which was approximately 19.7-fold greater than that observed in the basal medium. Amongst the various surface-active agents tested in lipase production, Tween-80 (1% (v/v)) was the best; an approximately 19.4-fold increase in lipase production was observed, as compared to the basal medium. Ü. AÇIKEL, M. ERŞAN, Y. SAĞ AÇIKEL When the stirring rate was increased from 50 to 250 rpm lipase activity (103.12 U/L) increased up to 200 rpm, and then decreased. The effect of the aeration rate was the same order of magnitude as that of the stirring rate. Maximum lipase activity (102.83 U/L) occurred at the 2-vvm aeration rate. To increase the effect of the carbon source on enzyme activity the combined effect of molasses sucrose and sucrose was investigated. Maximum lipase activity of 92.27 U/L was observed at the 5-g/L of sucrose concentration, which was approximately 36.5-fold greater than that observed in the absence of molasses, and 19.5-fold greater than that observed in the fermentation medium that did not contain sucrose. Then sunflower oil (0.5% v/v) as an inducer was added to the fermentation medium containing both molasses and sucrose, and lipolytic activity increased to 219.71 U/L. The presence of Tween-80 in the fermentation medium containing molasses sucrose, sucrose, and sunflower oil stimulated the release of the enzyme, increasing lipolytic activity (505.42 U/L) in the culture medium 2.30-fold. was observed in response to Ca2+ and Mg2+, whereas 2+ 2+ Fe and Mn decreased enzyme activity. In the presence of Fe ions lipase activity was reduced by 83% (85.23 U/L). The most negative effect was noted in the presence of Co2+ and Ni2+ salts. The enzyme appeared to be insensitive to EDTA, whereas a 1.25-fold increase in lipase activity occurred in the presence of gum arabic. As a result, controlling the culturing conditions and modifying the composition of the medium dramatically improved the production of R. delemar lipase. Acknowledgements The authors wish to thank TÜBİTAK (the Scientific and Technological Research Council of Turkey) for partial financial support of this study (project no: MİSAG-282). We also wish to thank Jeneil Biosurfactant Co. (Saukville, WI, USA) for supplying the rhamnolipid biosurfactant. Corresponding author: The salts of Na+ and K+ had the most positive effects on enzyme activity. In the presence of Na+ and K+ lipase activity reached 964.55 and 934.41 U/L, which was approximately 204-fold and 197-fold greater, respectively, than that observed in the basal medium that contained molasses sucrose only. Testing bivalent cations showed that the greatest stimulation Ünsal AÇIKEL Department of Chemical Engineering, Cumhuriyet University, 58140 Campus, Sivas - TURKEY E-mail: uacikel@cumhuriyet.edu.tr References 1. 2. 3. Ellaiah P, Prabhakar T, Ramakrishna B et al. Production of lipase by immobilized cells of Aspergillus niger. Process Biochem 39: 525-528, 2004. Wisdom RA, Dunnill P, Lilly MD. Enzymic interesterification of fats: laboratory and pilot-scale studies with immobilized lipase from Rhizopus arrhizus. Biotechnol Bioeng 29: 1081-1085, 1987. Tweddell RJ, Kermasha S, Combes D et al. Esterification and interesterification activities of lipases from Rhizopus niveus and Mucor miehei in three different types of organic media: a comparative study. Enzyme Microb Tech 22: 439-445, 1998. 4. Chowdary GV, Ramesh MN, Prapulla SG. Enzymic synthesis of isoamyl isovalerate using immobilized lipase from Rhizomucor miehei: a multivariate analysis. Process Biochem 36: 331-339, 2000. 5. Sharma R, Chisti Y, Banerjee UC. Production, purification, characterization, and applications of lipases. Biotechnol Adv 19: 627-662, 2001. 6. Hasan F, Shah AA, Hameed A. Industrial applications of microbial lipases. Enzyme Microb Tech 39: 235-251, 2006. 7. Stransky K, Zarevucka M, Kejik Z et al. Substrate specificity, regioselectivity and hydrolytic activity of lipases activated from Geotrichum sp. Biochem Eng J 34: 209-216, 2007. 8. Joseph B, Ramteke PW, Thomas G. Cold active microbial lipases: Some hot issues and recent developments. Biotechnol Adv 26: 457-470, 2008. 9. Li N, Zeng QM, Zong MH. Substrate specificity of lipase from Burkholderia cepacia in the synthesis of 3’-arylaliphatic acid esters of floxuridine. J Biotechnol 142: 267-270, 2009. 10. Couto SR, Sanroman MA. Application of solid-state fermentation to food industry - A review. J Food Eng 76: 291302, 2006. 11. Liu R, Jiang X, Mou H et al. A novel low-temperature resistant alkaline lipase from a soda lake fungus strain Fusarium solani N4-2 for detergent formulation. Biochem Eng J 46: 265-270, 2009. 43 The effects of the composition of growth medium and fermentation conditions on the production of lipase by R. delemar 12. Gotor-Fernandez V, Brieva R, Gotor V. Lipases: Useful biocatalysts for the preparation of pharmaceuticals. J Mol Catal B-Enzym 40: 111-120, 2006. 25. Wonderwülbecke T, Kieslich K, Erdman H. Comparison of lipases by different assays. Enzyme Microb Tech 14: 631-639, 1992. 13. Jaeger KE, Reetz TM. Microbial lipases from versatile tools for biotechnology. Trends Biotechnol 16: 396-403, 1998. 26. 14. Perez JPH, Lopez-Cabarcos E, Lopez-Ruiz B. The application of methacrylate-based polymers to enzyme biosensors. Biomol Eng 23: 233-245, 2006. Li D, Wang B, Tan T. Production enhancement of Rhizopus arrhizus lipase by feeding oleic acid. J Mol Catal B-Enzym 43: 40-43, 2006. 27. Elibol M, Özer D. Lipase production by immobilised Rhizopus arrhizus. Process Biochem 36: 219-223, 2000. 28. Rodriguez JA, Mateos JC, Nungaray J et al. Improving lipase production by nutrient source modification using Rhizopus homothallicus cultured in solid state fermentation. Process Biochem 41: 2264-2269, 2006. 29. Espinosa E, Sanchez S, Farres A. Nutritional factors affecting lipase production by Rhizopus delemar CDBB H313. Biotechnol Lett 12: 209-214, 1990. 30. Li CY, Cheng CY, Chen TL. Fed-batch production of lipase by Acinetobacter radioresistens using Tween-80 as the carbon source. Biochem Eng J 19: 25-31, 2004. 15. Umare SS, Chandure AS. Synthesis, characterization and biodegradation studies of poly(ester urethane)s. Chem Eng J 142: 65-77, 2008. 16. Dizge N, Aydiner C, Imer DY et al. Biodiesel production from sunflower, soybean, and waste cooking oils by transesterification using lipase immobilized onto a novel microporous polymer. Bioresource Technol 100: 1983-1991. 17. Salameh M, Wiegel J. Lipases from extremophiles and potential for industrial applications. Adv Appl Microbiol 61: 253-283. 18. Dharmsthiti S, Kuhasuntisuk B. Lipase from Pseudomonas aeruginosa LP602: biochemical properties and application for wastewater treatment. J Ind Microbiol Biot 21: 75-80, 1998. 31. Asses N, Ayed L, Bouallagui H et al. Use of Geotrichum candidum for olive mill wastewater treatment in submerged and static culture. Bioresource Technol 100: 2182-2188, 2009. Labuschagne RB, Tonder AV, Litthauer D. Flavobacterium odoratum lipase: Isolation and characterization. Enzyme Microb Tech 21: 52-58, 1997. 32. Iızumı T, Nakamura K, Fukase T. Purification and characterization of a thermostable lipase from newly isolated Pseudomonas sp. KWI-56. Agric Biol Chem 54: 1253-1258, 1990. 33. Sharon C, Nakazato M, Ogawa HI et al. Lipase-induced hydrolysis of castor oil: effect of various metals. J Ind Microbiol Biotechnol 21: 292-295, 1998. 34. Hiol A, Jonzo MD, Rugani N et al. Purification and characterization of an extracellular lipase from a thermophilic Rhizopus oryzae strain isolated from palm fruit. Enzyme Microb Tech 26: 421-430, 2000. 35. Chandan RC, Shahani KM. Role of sulfhydryl groups in the activity of milk lipase. J Dairy Sci 48: 1413-1418, 1965. 36. Liebeton K, Zacharias A, Jaeger KE. Disulfide bond in Pseudomonas aeruginosa lipase stabilizes the structure but is not required for interaction with its foldase. J Bacteriol 183: 597603, 2001. 19. 20. Haas MJ, Cichowicz DJ, Bailey DG. Purification and characterization of an extracellular lipase from the fungus Rhizopus delemar. Lipids 27: 571-576, 1992. 21. Joerger RD, Haas MJ. Overexpression of a Rhizopus delemar lipase gene in Escherichia coli. Lipids 28: 81-88, 1993. 22. Joerger RD, Haas MJ. Alteration of chain length selectivity of a Rhizopus delemar lipase through site-directed mutagenesis. Lipids 29: 377-384, 1994. 23. Giuseppin MLF. Effects of dissolved oxygen concentration on lipase production by Rhizopus delemar. Appl Microbiol Biot 20: 161-165, 1984. 24. Nadeem M, Qazi JI, Syed Q et al. Optimization of Process Parameters for Alkaline Protease Production by Bacillus licheniformis N-2 and Kinetics Studies in Batch Fermentation. Turk J Biol 32: 243-251, 2008. 44