020815000252AbstractForSuschem

advertisement

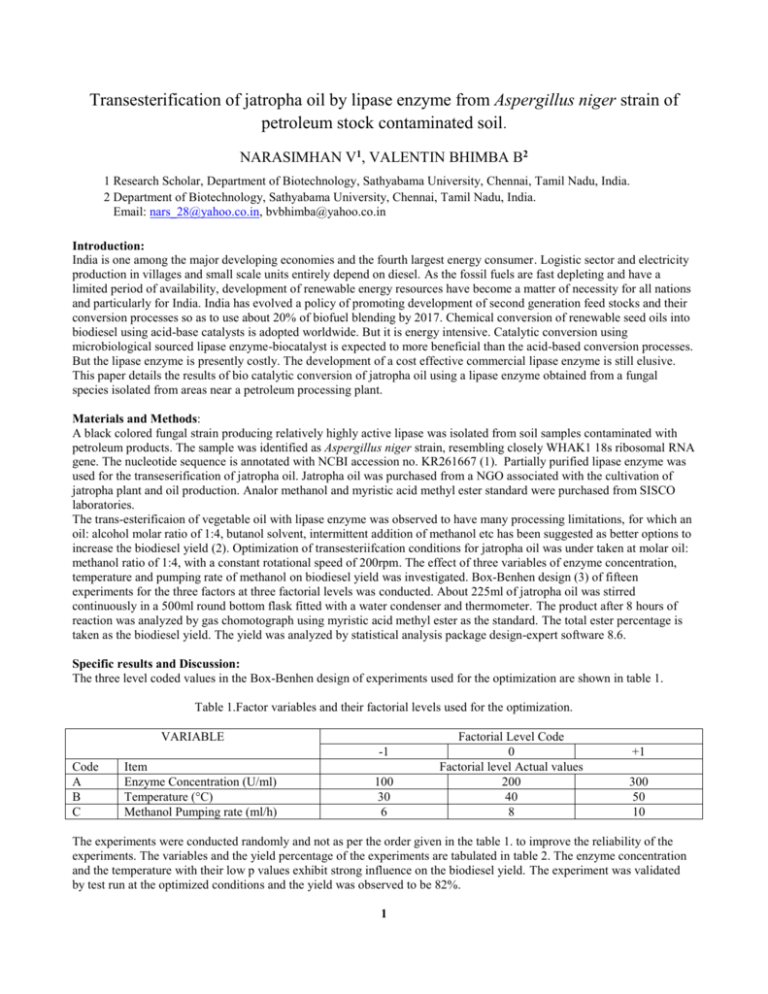

Transesterification of jatropha oil by lipase enzyme from Aspergillus niger strain of petroleum stock contaminated soil. NARASIMHAN V1, VALENTIN BHIMBA B2 1 Research Scholar, Department of Biotechnology, Sathyabama University, Chennai, Tamil Nadu, India. 2 Department of Biotechnology, Sathyabama University, Chennai, Tamil Nadu, India. Email: nars_28@yahoo.co.in, bvbhimba@yahoo.co.in Introduction: India is one among the major developing economies and the fourth largest energy consumer. Logistic sector and electricity production in villages and small scale units entirely depend on diesel. As the fossil fuels are fast depleting and have a limited period of availability, development of renewable energy resources have become a matter of necessity for all nations and particularly for India. India has evolved a policy of promoting development of second generation feed stocks and their conversion processes so as to use about 20% of biofuel blending by 2017. Chemical conversion of renewable seed oils into biodiesel using acid-base catalysts is adopted worldwide. But it is energy intensive. Catalytic conversion using microbiological sourced lipase enzyme-biocatalyst is expected to more beneficial than the acid-based conversion processes. But the lipase enzyme is presently costly. The development of a cost effective commercial lipase enzyme is still elusive. This paper details the results of bio catalytic conversion of jatropha oil using a lipase enzyme obtained from a fungal species isolated from areas near a petroleum processing plant. Materials and Methods: A black colored fungal strain producing relatively highly active lipase was isolated from soil samples contaminated with petroleum products. The sample was identified as Aspergillus niger strain, resembling closely WHAK1 18s ribosomal RNA gene. The nucleotide sequence is annotated with NCBI accession no. KR261667 (1). Partially purified lipase enzyme was used for the transeserification of jatropha oil. Jatropha oil was purchased from a NGO associated with the cultivation of jatropha plant and oil production. Analor methanol and myristic acid methyl ester standard were purchased from SISCO laboratories. The trans-esterificaion of vegetable oil with lipase enzyme was observed to have many processing limitations, for which an oil: alcohol molar ratio of 1:4, butanol solvent, intermittent addition of methanol etc has been suggested as better options to increase the biodiesel yield (2). Optimization of transesteriifcation conditions for jatropha oil was under taken at molar oil: methanol ratio of 1:4, with a constant rotational speed of 200rpm. The effect of three variables of enzyme concentration, temperature and pumping rate of methanol on biodiesel yield was investigated. Box-Benhen design (3) of fifteen experiments for the three factors at three factorial levels was conducted. About 225ml of jatropha oil was stirred continuously in a 500ml round bottom flask fitted with a water condenser and thermometer. The product after 8 hours of reaction was analyzed by gas chomotograph using myristic acid methyl ester as the standard. The total ester percentage is taken as the biodiesel yield. The yield was analyzed by statistical analysis package design-expert software 8.6. Specific results and Discussion: The three level coded values in the Box-Benhen design of experiments used for the optimization are shown in table 1. Table 1.Factor variables and their factorial levels used for the optimization. VARIABLE -1 Code A B C Item Enzyme Concentration (U/ml) Temperature (°C) Methanol Pumping rate (ml/h) 100 30 6 Factorial Level Code 0 Factorial level Actual values 200 40 8 +1 300 50 10 The experiments were conducted randomly and not as per the order given in the table 1. to improve the reliability of the experiments. The variables and the yield percentage of the experiments are tabulated in table 2. The enzyme concentration and the temperature with their low p values exhibit strong influence on the biodiesel yield. The experiment was validated by test run at the optimized conditions and the yield was observed to be 82%. 1 Table 2. Experimental design and their yield Experiment No 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 Variable code A B C +1 +1 0 +1 -1 0 -1 +1 0 -1 -1 0 +1 0 +1 +1 0 -1 -1 0 +1 -1 0 -1 0 +1 +1 0 +1 -1 0 -1 +1 0 -1 -1 0 0 0 0 0 0 0 0 0 Biodiesel % Yield 40 79 20 40 54 56 40 40 25 35 60 63 54 54 56 Conclusion: Jatropha oil was transesterified with lipase obtained from an Aspergillus niger strain isolated from petroleum stock contaminated soil. A yield of 82.5% was obtained for 225g oil with 40ml methanol pumped at the rate of 8ml/h at a 30°C in a continuously stirred round bottom flask at 200rpm. Reference: 1. V.Narasimhan and B.Valentin bhimba, Int j pharm bio sci 6(3): (b), 2015 july; 637 – 644 2. D. Meher, Vidya Sagar, S.N. Naik Renewable and Sustainable EnergyRreviews xx (xxxx) 1-21 3. Douglas C.Montgomery, Design and Analysis of experiments, Fifth Edition, John Wiley & Sons, Inc. 2