MSc Chapter4 (Final)

advertisement

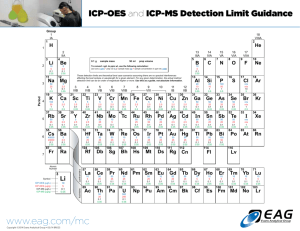

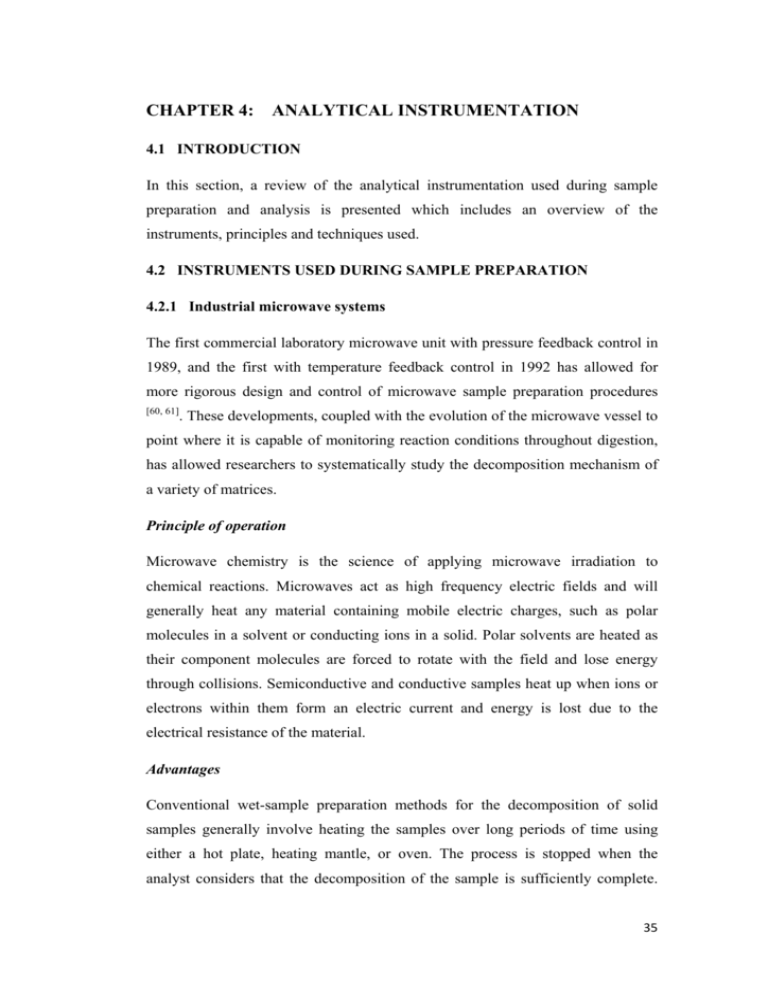

CHAPTER 4: ANALYTICAL INSTRUMENTATION 4.1 INTRODUCTION In this section, a review of the analytical instrumentation used during sample preparation and analysis is presented which includes an overview of the instruments, principles and techniques used. 4.2 INSTRUMENTS USED DURING SAMPLE PREPARATION 4.2.1 Industrial microwave systems The first commercial laboratory microwave unit with pressure feedback control in 1989, and the first with temperature feedback control in 1992 has allowed for more rigorous design and control of microwave sample preparation procedures [60, 61] . These developments, coupled with the evolution of the microwave vessel to point where it is capable of monitoring reaction conditions throughout digestion, has allowed researchers to systematically study the decomposition mechanism of a variety of matrices. Principle of operation Microwave chemistry is the science of applying microwave irradiation to chemical reactions. Microwaves act as high frequency electric fields and will generally heat any material containing mobile electric charges, such as polar molecules in a solvent or conducting ions in a solid. Polar solvents are heated as their component molecules are forced to rotate with the field and lose energy through collisions. Semiconductive and conductive samples heat up when ions or electrons within them form an electric current and energy is lost due to the electrical resistance of the material. Advantages Conventional wet-sample preparation methods for the decomposition of solid samples generally involve heating the samples over long periods of time using either a hot plate, heating mantle, or oven. The process is stopped when the analyst considers that the decomposition of the sample is sufficiently complete. 35 This type of open-vessel digestion has many limitations including the use of large volumes of reagents, a real potential for sample contamination by external materials and the laboratory environment, and the potential exposure of the analyst and the laboratory to corrosive fumes. Closed-vessel microwave decomposition uses significantly different technology to achieve sample decomposition. Decomposition of most solid samples can be achieved using only 10 mL reagent, and can be completed in a short period of time. The higher temperatures achieved in the closed system give microwave digestion a kinetic advantage over hot plate digestion, as described by the Arrhenius Equation: (d ln k)/(dT) = (Ea)/(RT2) (4.1) Integration of this equation gives: (k2/ lnk1) = (Ea)/(2.303R)[(1/T1) – (1/T2)] (4.2) In this expression k1 and k2 are rate constants for the reaction of interest at T1 and T2 respectively, Ea is the activation energy, and R is the ideal gas constant. These equations show that the reaction rate increases exponentially with increasing temperature. This translates into approximately a 100-fold decrease in the time required to carry out a digestion at 175 °C when compared to a digestion at 95 °C. In addition, because the mineral acid converts microwave energy into heat almost instantaneously, rapid heating of the sample is achieved, further decreasing the reaction time. Digestions are also more complete because many acids (e.g. nitric acid) show improved oxidation potential at elevated temperatures. A typical closed microwave system with build-in pressure and temperature control can be seen in Figure 4.1 and Figure 4.2 which also show the microwave consumables used during routine operation. 36 Figure 4.1 CEM Mars 5 microwave systems in operation, (Photographed by, Impala laboratory management, 2006) Figure 4.2 CEM Mars microwave 5 systems with high pressure and temperature consumables, (Photographed by Impala laboratory management, 2006) 37 4.3 INSTRUMENTS USED FOR SAMPLE MEASUREMENT 4.3.1 Inductively coupled plasma optical emission spectrometry (ICP-OES) ICP-OES instruments are used for a number of different applications in a variety of industries. In the mining industry, ICP-OES is used in conjunction with x-ray fluorescence spectroscopy for the analysis of major elements. Principle of operation The first investigations of alkali and alkali earth elements with the aid of a spectroscope were reported by Bunsen and Kirchhoff in 1860. Spectrochemical analysis was further developed in the 20th century when flame, arc and spark technology were introduced [66]. An illustration of an ICP-OES as it appears today is shown in Figure 4.3. Figure 4.3 An illustration of a SPECTRO GENESIS ICP-OES as provided by SPECTRO, S.A. The principle of operation involves a sample introduction system which supplies sample at a constant rate to the ICP emission source (plasma), where desolvation, atomization, excitation and light emission occur. During the excitation process, molecular, atomic and ionic species in various energy stages are produced. Energy is released in the form of electromagnetic radiation 38 and, as a result, a wavelength is formed, which is characteristic of the emitting specie. An expression for the absolute intensity (Iqp) of a spontaneous emission line arriving from an electronic transition from a higher state q to lower state p can be shown to be: [64,65] Iqp = d/4π Aqp hvqp Nq (4.3) Where d is the depth of source, vqp is the transition frequency, Aqp is the line transition probability, h is Planck’s constant and Nq is the number of excited level species. The intensity of an elemental atomic and ion line is used as the analytical signal in quantitative atomic emission spectroscopy. Components of the ICP-OES instrument include the peristaltic pump, the nebuliser, the spray chamber, the rf generator, the torch, the optical systems, the detectors and the data processing system. The ICP-OES components are displayed in figure 4.4 and are discussed briefly thereafter. Figure 4.4 The SPECTRO CIROS ICP-OES schematic diagram as provided by SPECTRO, S.A. 39 Nebulizer and spray chamber The nebulizer works in conjunction with the spray chamber. The major function of the spray chamber is to act as a droplet size discriminator, passing only droplets below a certain size. The size of droplets passed by the spray chamber will largely depend upon the geometry of the spray chamber, but to a lesser extent will depend upon the gas flow rate. A further function of the spray chamber is to dampen pulses originating from the peristaltic pump. Torch, rf generator and coil Plasma RF power primarily affects the plasma temperature i.e. the greater the power intake, the higher the plasma temperature. The net effect of power on analyte sensitivity depends on the ratio of analyte signal to background noise. Most plasmas are operated between 0.8 – 1.1 KW, with the exact power chosen in accordance with the most crucial elements to be evaluated. The plasma is sustained by energy from the RF Generator and coil. The ICP – OES torch is centered within the induction coil, and the center tube is 1-2 mm below the bottom of the induction coil. The three concentric quartz tubes of the torch serve to define three separate gas flow paths i.e. the coolant, auxiliary and carrier gas paths. Plasma discharge Radio frequency energy from the induction coil causes charged particles to accelerate in a circular pathway in the same plane as the coil windings. These charged particles collide with Argon gas atoms, causing ionization and thereby forming a plasma. High in the plasma is the radiation zone, where excitation, ionization, and emission take place. This region (approximately 6000 to 7000 oK) is normally utilised for analytical measurement. Optics The spectrometer isolates analytical wavelengths from the emitted light plasma. The majority of wavelengths lie within the region 160 to 860 nm . Separation of light into its component wavelengths is normally achieved 40 using a diffraction grating. There are three types of diffraction grating: ruled, holographic and echelle grating. Many spectrometers are either flushed with nitrogen or argon or are maintained under vacuum to remove any oxygen. Detectors New generation detectors have recently been introduced. These are solid-state detectors, but are also referred to as charged - transfer devices. There are two sub-classifications: charge – coupled devices (CCDs) and charge-injection devices (CIDs). A CID consists of a two dimensional array of detector elements which, when coupled to an Echelle spectrometer, is capable of simultaneous line analysis over the range 170 -800 nm. Readout devices and data processing The detector produces an electrical signal which is processed by an electronic circuit before being measured by a read-out device. In modern spectrometers the computer controls the operating parameters of the plasma as well as performing the task of sample logging, operation of the auto-samplers, construction of calibration curves and facilitates the rapid and efficient handling of data. 4.3.2 Inductively coupled plasma mass spectroscopy (ICP-MS) Since the commercialization of ICP-MS in 1983 [64] , it has undoubtedly been the fastest growing trace element technique for a series of applications. The platinum industry however, only truly started employing this technique for the analysis of exploration samples, Final Tailings streams and Mill Circuit Product streams for trace levels of precious metals about six years ago. And as yet ICP-MS is still not perceived as an instrument for routine evaluation analysis unlike FAAS and ICPOES. Principle of operation The principle of operation for ICP-MS is similar to that of ICP-OES and includes a sample introduction system which supplies sample at a constant 41 rate to the ICP emission source (plasma). It is important to differentiate the function of the plasma in ICP-MS compared to that in an ICP-OES. In ICP-OES the plasma is used to generate photons of light, by the excitation of electrons of a ground-state atom to higher energy level. Wavelength specific photons are emitted, which are characteristic of the element of interest. A schematic setup of an ICP-MS is shown in Figure 4.5. Figure 4.5 A Schematic setup of the SPECTRO MASS 2000 ICP-MS provided by SPECTRO, S.A In ICP-MS the plasma is used to generate positively charged ions and not photons. Once the ions are present in the plasma, they are projected via a low vacuum interface into the mass spectrometer chamber and focused via an ion lens system onto a quadrupole mass filter, Figure 4.5. The interface region consists of two metallic cones (usually nickel), called the sampler and skimmer cones which allow the ions to pass through to the ion optics, Figure 4.6. The ions which reach the quadropole are separated based on their mass- to- charge ratio prior to the detector and to filter out all the nonanalyte, interfering and matrix ions. The final step is to convert the ions into an electrical signal with a dynode detector. 42 Figure 4.6 The interface region and ion optics of an ICP-MS system as provided by SPECTRO, S.A 4.3.3 Graphite atomic absorption spectroscopy (GFAAS) The use of furnaces as atomizers for atomic absorption spectroscopy was a major breakthrough as it allowed the measurement of very low concentrations when compared to that achievable by flame atomic absorption spectroscopy. Principle of operation There are many different high temperature furnace designs. The objective of GFAAS is to generate free atoms such that atomic absorption can be measured. The principle of operation involves three stages: [67,69] • A drying stage during which, the solvent is removed and dried to a salt deposit. • An ashing stage which removes organic or inorganic material. • An atomization stage in which free atoms are formed within a small zone. The absorption signal produced in the atomization stage is a sharp peak, the height of which can be related to the amount of analyte element present. The GFAAS 43 can achieve low limits of detection as the sample is completely atomized and vaporized and the atoms are kept in the atomic reservoir for an extensive period. 4.4 COMPARING GFAAS, ICP-OES and ICP-MS TECHNIQUES Atomic spectroscopic methods have many advantages which include: linear dynamic ranges, low detection limits, easy and rapid qualitative analysis, simultaneous multi-element analysis, good precision and high sensitivity. Specific criteria are used to choose appropriate atomic spectroscopic methods for different applications. A series of criteria shall be utilised to highlight the respective advantages of the GFAAS, ICP-OES and ICP-MS techniques. Detection limits Typical detection limit ranges for major atomic spectroscopy techniques are shown in Table 4.1. Table 4.1 Detection limit ranges [70-72] Atomic spectroscopy techniques Detection limit range (μg/L) FAAS 1 – 1000 ICP-OES – Radial view 1 – 100 ICP-OES – Axial view 0.1 – 10 Hydride generation FAAS 0.01 – 1 GFAAS 0.01 – 0.1 ICP-MS 0.001 – 0.01 It is clear from the data in Table 4.1. , that ICP-MS offers the lowest detection limit followed by GFAAS and axial ICP-OES. Radial ICP-OES and FAAS show similar detection limits, but ICP-OES can atomize refractory and rare earth elements more effectively due to the higher temperature that can be achieved by a plasma as when compared to a flame. Hydride generation FAAS offers exceptional detection limits for mercury (Hg), arsenic (As), bismuth (Bi), antimony (Sb), selenium (Se) and tellurium (Te). ICP-MS in conjunction with 44 collision / reaction cells or magnetic sector technology can achieve detection limits as low as parts-per-quadrillion (ppq) for many elements [63] . It is important to emphasize that these detection limits are only achievable in simple matrixes. Linear dynamic range (LDR) ICP-MS is considered to be an ultra-trace element technique which has an LDR in excess of 105. GFAAS has a limited LDR of 102 – 103, but can be used for higher concentrations when a less sensitive analytical line is used. ICP-OES is used for trace and major element analysis with a LDR of 105. Precision Short and long term precision are a good indication of how stable an instrument is. Precision is usually expressed in percent relative standard deviation (%RSD). The short term precision for ICP-MS is between 1 to 3 %RSD and the long term precision is less than 5 %RSD. The short term precision for ICP-OES is between 0.3 – 2 %RSD and the long term precision depending on the nebulizer should be not more than 3 %RSD. Precision for both ICP-OES and ICP-MS may be improved by using internal standardisation. GFAAS has a short term precision of between 0.5 – 5 % RSD, but long term precision is more a function of the number of graphite tube firings than time [63]. Interferences Although appropriate techniques are chosen for each application by experienced staff, interferences still need to be addressed during method development. Specific interference common to various techniques are shown in Table 4.2. 45 Table 4.2 Summary of instrumental interferences [73,74] Technique Type of interference Method of compensation FAAS Ionisation Chemical Ionisation buffers Release agents or nitrous oxide-acetylene flame Dilution, matrix matching or standard addition Physical GFAAS Chemical, physical Standard temperature platform furnace conditions, matrix modifiers, standard addition Molecular absorption Zeeman or continuum source background correction Spectral ICP-OES ICP-MS Zeeman background correction Spectral Background correction Inter elemental corrections Alternate analytical line Matrix effects Internal standardization Ionization Spectral Ionization buffers Background correction Inter elemental correction Alternate analytical lines Matrix acids Doubly charged ions Matrix effects Ionization Higher resolution systems to resolve masses less than 1 amu apart Internal standard Matrix matching, sample dilutions, standard addition, isotope dilutions Matrix matching, internal standard Space charged effects Isobaric effects Analysis time and sample throughput Analysis time and sample throughput rates are influenced by the accuracy and precision required plus the type of instrument employed. FAAS is a simple and fast technique with a measurement time of less than 30 s per replicate of 3 integrations. ICP-OES and ICP-MS have measurements times of about 3 min per 46 replicate of 3 integrations, while GFAAS is a very tedious technique with a measurement time of up to 5 min per replicate of 3 integrations. General The most commonly employed instrumental techniques in the platinum industry are that of FAAS, GFAAS, X-ray fluorescence spectroscopy, ICP-OES and their capabilities and analytical limitations are well known. ICP-OES would appear to have become the most popular routine technique for inorganic multi-elemental analysis of dissolved samples, despite requiring significant capital investment and having running expenses which are much higher than those for FAAS. 4.5 INSTRUMENTATION FOR THE IDENTIFICATION OF MINERALS. 4.5.1 Scanning electron microscope (SEM) SEM uses a focused beam of high-energy electrons that generate signals which reveal information about the sample such as external morphology, chemical composition, crystalline structure and the orientation of the sample composition. Principle of operation Accelerating electrons in a SEM carrying significant kinetic energy generate radiation signals when the electrons are decelerated in a solid sample as a result of electron interactions. These signals include secondary electrons (which produce SEM images), backscattered electrons (BSE), diffracted backscattered electrons (EBSD) (which are used to determine crystal structures and the orientation of minerals), photons (characteristic X-rays that are used for elemental analysis and continuum X-rays), visible light and heat [76]. Many SEM installations have an energy dispersive X-ray detector system (EDS), which allows for spectral analysis of X-rays generated from the sample directly under the electron beam. X-ray generation is produced by inelastic collisions of incident electrons with electrons in discrete atomic orbitals. As the excited electrons return to lower energy states, they yield X-rays of a fixed wavelength. 47 Characteristic X-rays are produced for each element in a mineral which is "excited" by the electron beam. Advantages and disadvantages Some advantages of this technique include are as follows: • Excellent characterization of solid samples. • The electron beam can be scanned over a very small area of the sample. • SEM in conjunction with an EDS detector allows morpholograpic, topographic, crystallographic and compositional information to be obtained rapidly and simultaneously from the same area. • SEM analysis is considered to be "non-destructive", meaning there is no volume loss of the sample, and as such it is possible to analyze the same materials repeatedly. Unfortunately, SEM cannot detect very light elements (H, He and Li) or elements with an atomic number less than 11. Although SEM with an EDS detector is fast and easy to use, it suffers from poor energy resolution and poor sensitivity towards elements present in low abundance compared to wavelength dispersive X-ray detectors (WDS) or electron probe micro analyzers (EPMA). 4.5.2 Electron probe micro-analyzer (EPMA) The EPMA is a micro-beam instrument used for the in situ non-destructive chemical analysis of minute solid inclusions [75]. Principle of operation An electron microprobe operates under the principle that if a solid material is bombarded by an accelerated and focused electron beam, the incident electron beam has sufficient energy to dislodge inner-shell electrons of the constituent atoms in the sample to be analyzed. Outer-shell electrons fill these inner-shell vacancies, losing energy by the emission of characteristic X-rays as in X-ray 48 fluorescence. These electrons can be focused to a very fine beam through a set of electromagnetic lenses between the electron source and the sample to be analyzed. The X-rays generated are analysed by a crystal spectrometer with wavelength dispersive X-ray detector. Of most common interest in the analysis of geological materials are secondary and back-scattered electrons, which are useful for surface imaging or obtaining an average composition of the material. The electron optical path and X-ray spectrometer of an electron microprobe are illustrated in Figure 4.7. Figure 4.7 microprobe The electron optical path and x-ray spectrometer of an electron [68] . Advantages and disadvantages Some advantages of this technique are as follows: • Although similar to SEM it is equipped with a range of crystal spectrometers which enable quantitative chemical analysis at high sensitivity. 49 • The EPMA is capable of analysing sample areas as small as 1-2 micron diameter and even minute single phases in a material. • Chemical analyses can be obtained in situ, which allows the detection of small compositional variations within chemically zoned material. • It is considered to be a “non-destructive” technique. EPMA is also unable to detect the very light elements (H, He and Li) and as a result cannot detect “water” in hydrous minerals. It is also known that some elements generate x-rays with overlapping peak positions which need to be separated. The absolute detection limit for most elements is not as good as that achievable by x-ray fluorescence because of the presence of a continuum spectrum. Nevertheless, the ability of an EPMA to obtain quantitative chemical analysis on a minute volume of sample or mineral grain ensures its continued popularity in the study of minerals. 50