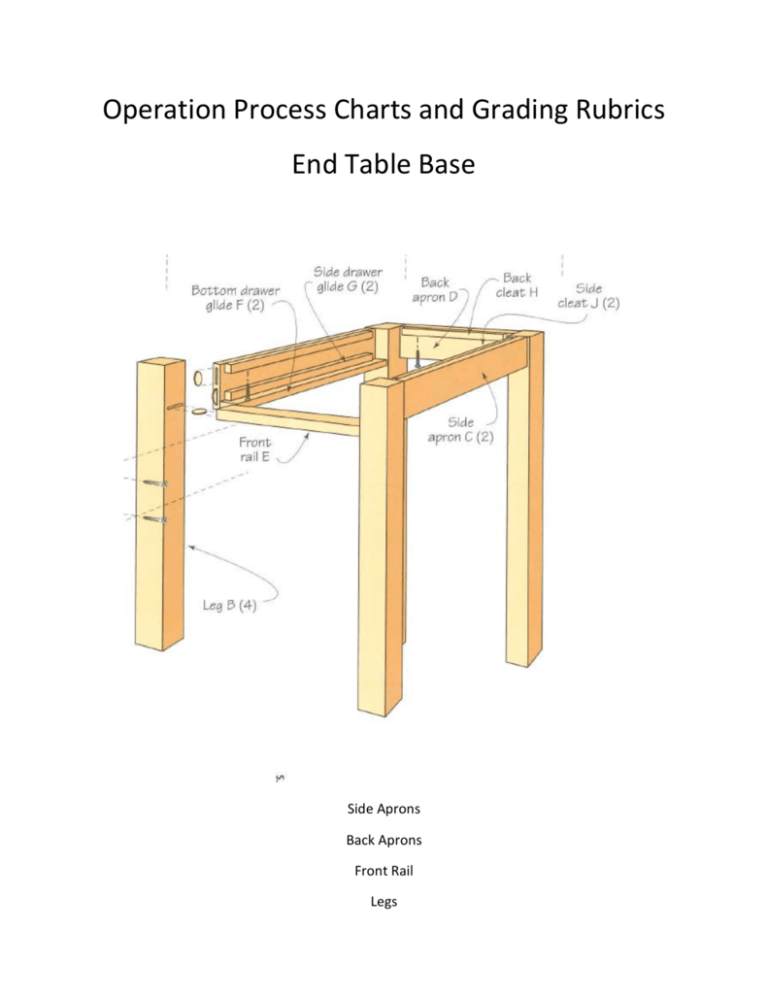

Operation Process Charts and Grading Rubrics End Table Base

advertisement

Operation Process Charts and Grading Rubrics End Table Base Side Aprons Back Aprons Front Rail Legs Student Name:________________________________ Period:________ End Table BACK APRON Operation Process Chart & Rubric BACK APRON OPERATION PROCESS CHART Task 1. Description of Task Qnty Equipment Tooling Conduct Squaring process to the BACK APRON’s final dimensions. (see your squaring the BACK APRON sheet) 1 Multiple Multiple 1 Biscuit jointer jig 1 Biscuit Jointer Biscuit jointer jig 1 Hand Drill Krieg’s Jig Mark both ends on BACK APRON for biscuit jointer location 2. 3. 4. 5. Set Biscuit Jointer for #10 Biscuits and Biscuit Joint both ends of the BACK APRON. Measure and strike a line 2” in from each end and drill table top holding fixture with the “Krieg’s Jig” Submit to instructor for Assessment BACK APRON RUBRIC Level of Evidence Mastery 5 Thickness (3/4”) Proficient 4 Width (5”) Lost points The Student demonstrated basic measuring concepts. Not Proficient 3..2..1..0 Length (15”) All Dimensions are precise ≥1/16 “ < 1/8” ≥1/8” < 3/16” ≥3/16” The Student fabricated components accurately Level of Evidence Mastery 5 Individual components show evidence of proper squaring technique. . All adjacent surfaces are 90 degrees of one another. Both edges and faces have been surfaced and both ends were crosscut. Biscuit joint done correctly Biscuit Joints are spaced correctly, are centered with the thickness of the board and are the correct depth for a #10 Biscuit Krieg’s Jig points are correct Krieg’s Jig drilling point are 2” in from ends and smaller opening barely breaks through the edge Total Points Lost -1 -3 Total Points Possible Total Points Received 5 -5 15 POINTS Proficient 4 Not Proficient 3..2..1..0 Surfaces are slightly off of 90 degrees : o Face to Edge o Face to End o Edge to End o edges/faces not surfaced o ends not cut Biscuit Joints have some inconsistencies: o Not spaced correctly, o Not centered with the thickness of the board o Not correct depth for a #10 Biscuit Krieg’s Jig points have some inconsistencies: o Not spaced correctly o Screw opening Surfaces are considerable off of 90 degrees: o Face to Edge o Face to End o Edge to End o edges/faces not surfaced o ends not cut Biscuit Joints have many inconsistencies: o Not spaced correctly, o Not centered with the thickness of the board o Not correct depth for a #10 Biscuit Krieg’s Jig points have many inconsistencies: o Not spaced correctly o Screw opening Total Points of 20/ Pnts Rec. of 5 Comments Student Name:________________________________ Period:________ End Table SIDE APRONS Rubric OPERATION PROCESS CHART Task Description of Task Qnty Equipment Tooling 1. Conduct Squaring process to the SIDE APRONS’ final dimensions. (see squaring the SIDE APRONS sheet) 2 Multiple Multiple 2. Mark both ends on each of the SIDE APRONS for biscuit jointer location 2 Biscuit jointer jig 2 Biscuit Jointer Biscuit jointer jig 1 Hand Drill Krieg’s Jig 3. 4. 5. Set Biscuit Jointer for #10 Biscuits and Biscuit Joint all 4 ends of the SIDE APRONS. Measure and strike a line 2” in from each end and drill table top holding fixture with the “Krieg’s Jig” Submit to instructor for Formal Assessment RUBRIC Level of Evidence Mastery 5 Thickness (3/4”) Proficient 4 Width (5”) Not Proficient 3..2..1..0 Length (12”) All Dimensions are precise ≥1/16 “ < 1/8” ≥1/8” < 3/16” ≥3/16” Lost points The Student demonstrated basic measuring concepts. 5 Points Total Points Lost -1 -3 -5 Total Points Possible Total Points Received 5 The Student fabricated components accurately 15 Points Level of Evidence Mastery 5 Individual components show evidence of proper squaring technique. . All adjacent surfaces are 90 degrees of one another. Both edges and faces have been surfaced and both ends were crosscut. Biscuit joint done correctly Biscuit Joints are spaced correctly, are centered with the thickness of the board and are the correct depth for a #10 Biscuit Krieg’s Jig points are correct Krieg’s Jig drilling point are 2” in from ends and smaller opening barely breaks through the edge Proficient 4 Not Proficient 3..2..1..0 Surfaces are slightly off of 90 degrees : o Face to Edge o Face to End o Edge to End o edges/faces not surfaced o ends not cut Biscuit Joints have some inconsistencies: o Not spaced correctly, o Not centered with the thickness of the board o Not correct depth for a #10 Biscuit Krieg’s Jig points have some inconsistencies: o Not spaced correctly o Screw opening Surfaces are considerable off of 90 degrees: o Face to Edge o Face to End o Edge to End o edges/faces not surfaced o ends not cut Biscuit Joints have many inconsistencies: o Not spaced correctly, o Not centered with the thickness of the board o Not correct depth for a #10 Biscuit Krieg’s Jig points have many inconsistencies: o Not spaced correctly o Screw opening Total Points of 20 / Pnts Rec. of 5 Comments Student Name:________________________________ Period:________ End Table FRONT RAIL Operation Process Chart & Rubric OPERATION PROCESS CHART Task Description of Task Qnty Equipment Tooling 1. Conduct Squaring process to the FRONT RAIL’s final dimensions. (see your squaring the FRONT RAIL sheet) 1 Multiple Multiple 2. Mark both ends on FRONT RAIL for biscuit jointer location (1 ¼” in from edge or half the width) 1 3. Set Biscuit Jointer for #10 Biscuits and Biscuit Joint both ends of the FRONT RAIL. 1 4. Submit to instructor for Assessment Ruler Biscuit jointer jig Biscuit Jointer RUBRIC Level of Evidence Mastery 5 Thickness (3/4”) Proficient 4 Width (2 ½”) Not Proficient 3..2..1..0 Length (15”) All Dimensions are precise ≥1/16 “ < 1/8” ≥1/8” < 3/16” ≥3/16” The Student fabricated components accurately Level of Evidence Mastery 5 Individual components show evidence of proper squaring technique. . All adjacent surfaces are 90 degrees of one another. Both edges and faces have been surfaced and both ends were crosscut. Biscuit joint done correctly Biscuit Joints are spaced correctly, are centered with the thickness of the board and are the correct depth for a #10 Biscuit Proficient 4 Lost points The Student demonstrated basic measuring concepts. -1 -3 Total Points Possible Total Points Received 5 -5 10 POINTS Not Proficient 3..2..1..0 Surfaces are slightly off of 90 degrees : o Face to Edge o Face to End o Edge to End o edges/faces not surfaced o ends not cut Biscuit Joints have some inconsistencies: o Not spaced correctly, o Not centered with the thickness of the board o Not correct depth for a #10 Biscuit Total Points Lost Surfaces are considerable off of 90 degrees: o Face to Edge o Face to End o Edge to End o edges/faces not surfaced o ends not cut Biscuit Joints have many inconsistencies: o Not spaced correctly, o Not centered with the thickness of the board o Not correct depth for a #10 Biscuit Total Points of 15 / Pnts Rec. of 5 Comments Student Name:________________________________ Period:________ End Table LEGS Operation Process Chart & Rubric OPERATION PROCESS CHART Task Description of Task Qnty Equipment Tooling 1. Conduct Squaring process to the LEGS’ Pre-Fabrication dimensions. (see squaring the LEGS sheet) 5 Multiple Multiple 2. Edge-to-Edge Glue 5 pieces of stock per LEG. Be sure there are no gaps in the seams and completely eliminate excess glue. Allow to dry until next class period. 5 Pipe/Beam Clamps 3. Remove clamps and scrap any excess glue that may remain. 1 Scrapper 4. 5. 6. 7. Submit to instructor for Informal Assessment & Initials (5 Points) Joint one edge until true Rip to 2 ⅝” with jointed edge against the fence. Set planer to +1/16” of leg thickness, surface both faces until 2 ⅝” thick Rotate stock and surface both the edges and the faces until 2 ½” thick and wide Crosscut one end up to ½” from end then cut other end to final length (27 ¼”) Mark the appropriate edges and faces on all of the LEGS for biscuit jointer location Set Biscuit Jointer for #10 Biscuits, 7/8” inside the leg and Biscuit Joint all designated points of the LEGS. Router face to edge corners with ⅛” round over bit Submit to instructor for Formal Assessment 8. 9. 10. 11. 12. 13. Mr. Shock’s Initials: 1 JOINTER 1 Table Saw 1 Surface Planer 1 1 2 Fence Fence Surface Planer Miter / Radial Arm Saw Biscuit jointer jig 2 Biscuit Jointer 1 Router Table Fence Biscuit jointer jig Fence Student Name:________________________________ Period:________ End Table LEGS Operation Process Chart & Rubric RUBRIC Mastery 5 Level of Evidence All Dimensions are precise (measurements will be rounded up to the nearest 1/16”) Thickness (2 ½”) Proficient 4 Width (2 ½”) Length (27 ¼”) Not Proficient 3..2..1..0 ≥1/16 “ < 1/8” ≥1/8” < 3/16” ≥3/16” The Student fabricated components accurately Level of Evidence Mastery 5 Individual components show evidence of proper squaring technique. All adjacent surfaces are 90 degrees of one another. Both edges and faces have been surfaced and both ends were crosscut. Router Process done correctly All corners are router with 1/8” round over bit consistently covering the entire length of the legs Quality Control Check Obtains Initials on STEP 4 of Operation Process Chart Biscuit joint done correctly Lost points The Student demonstrated basic measuring concepts. 5 POINTS Biscuit Joints are spaced correctly, are centered with the thickness of the board and are the correct depth for a #10 Biscuit Level of Evidence Evidence of proper gluing techniques All joints are glued properly (No visible gaps between pieces) & sufficiently. There is no visible glue. Surfaces are slightly off of 90 degrees : o Face to Edge o Face to End o Edge to End o edges/faces not surfaced o ends not cut Most corners have gone through the Router process correctly: o Corners are router to 1/8” o Round over runs consistently the entire length of the leg Surfaces are considerable off of 90 degrees: o Face to Edge o Face to End o Edge to End o edges/faces not surfaced o ends not cut Some corners have gone through the Router process correctly: o Corners are router to 1/8” o Round over runs consistently the entire length of the leg DID NOT Obtains Initials on STEP 4 of Operation Process Chart Biscuit Joints have many inconsistencies: o Not spaced correctly, o Not centered with the thickness of the board o Not correct depth for a #10 Biscuit Some imperfections: o Glue is visible o Joints are not strong o Visible gaps between pieces 5 20 POINTS Not Proficient 3..2..1..0 Proficient 4 Total Points Received -5 The Student demonstrated knowledge of the use of fasteners and adhesives Mastery 5 Total Points Possible -1 -3 Proficient 4 Biscuit Joints have some inconsistencies: o Not spaced correctly, o Not centered with the thickness of the board o Not correct depth for a #10 Biscuit Total Points Lost Not Proficient 3..2..1..0 Many imperfections: o Glue is visible o Joints are not strong o Visible gaps between pieces TOTAL Pnts Rec. of 5 Comments 5 POINTS Pnts Rec. of 5 Comments _________/30 POINTS