Quantitative Biopharmaceutical Applications of Capillary Electrophoresis

A Thesis

Submitted to the Faculty

of

Drexel University

by

Junge Zhang

in partial fulfillment of the

requirements for the degree of

Doctor of Philosophy

November 2009

ii

© Copyright 2009

Junge Zhang. All Rights Reserved.

iii

Dedications

This thesis is dedicated to my wife Rene and my two beautiful daughters, Zannan and Melanie,

for their love, endless support, and understanding; to my loving father, who left this world in

2008 after fighting with stroke and cancer for eight years; and to my mother, who has been

giving me so much that I can never pay back.

iv

Acknowledgments

I would like to thank my research advisor, Professor Joe Foley for his support and guidance

during my study at Drexel University. I have learned so much from Dr. Foley thorough group

meetings, face-to-face discussions, and numerous phone calls and emails. You challenged me

for using scientifically incorrect citations that I thought to be authentic. You encouraged me to

keep working on my projects until I found the solutions. Because of your in-depth knowledge

and passion in separation science, I became a better analytical scientist. I would like to express

my sincerest gratitude to Dr. Foley, and without you this thesis would not be possible.

I would also like to thank my thesis committee: Dr. Peter Wade, Dr. Anthony Addison, Dr.

Reinhard Schweitz-Stenner, Dr. Felice Elefant, and Dr. Jonathan Shackman. Your time and

comments on my thesis are highly appreciated.

I must mention my former supervisor at J&J, Dr. Utpal Chakraborty. It was he who advised me

to study for the PhD after I joined the company. We became close friends after working

together for six years. Although we are in different groups now, your help and continuous

support are still tremendous and meant a lot to me. Thank you so much, Utpal!

I would like to thank my current supervisor at J&J, Dr. Sudhir Burman, who has reviewed two

of my manuscripts and provided valuable comments.

My thanks also go to the Foleite research group. At Drexel, the Foleite research group is like a

family to me. Many thanks to Dr. Melissa Mertzman, Dr. Kimberly Kahle, Dr. Stephanie

Schuster, Dr. Dave Thomas, Addy Kojtari, Alex Adair, Jeanine Erdner-Tindall, Anna

Caltabiano, Barbara Hale, Donna Blackney, Mirlinda Biba, Laquisha Hamilton, Li Li, and

v

Adam Socia. Your ideas and ways of solving a problem have inspired me in many ways.

Sometimes, even a simple question raised by one of you in a group meeting changed my way

of thinking. Your friendship is a blessing to me. Dr. Melissa was so caring and considerate. Dr.

Kim Kahle was so sharp and I wish I could be as smart as you are. Dr. Stephanie Schuster was

always smiling and nice to me even when I asked too many questions. Dr. Dave Thomas was

so patient and encouraging. Addy was always energetic and enthusiastic about science. Alex

was so perseverant. Although many times I had to make effort to go to a group meeting after a

hard working day, I’ll miss that after I graduate because it was such a good learning

opportunity for me.

I would like to thank many faculty and staff members in Chemistry Department at Drexel

University, particularly, to Dr. Anthony Addison, Dr. Alan Bandy, Dr. Peter Wade, Dr. Jun Xi,

Dr. Keven Owens, Dr. Reinhard Schweitz-Stenner, Virginia Nesmith, Edward Thorne, Edith

Smith, Edward Doherty, Susan Rutkowsky, and Thomas Cachaza.

Last, but not least, I would like to thank my wife Hong (Rene) Lu for her love. You have

sacrificed so much for me. I clearly remember those days and nights I had classes or group

meetings that you took care of the two kids. So many weekends I went to work on my project

and left you guys alone. At home whenever I worked on my research project, you never asked

me to do anything. Instead, you brought me a cup of tea to drink or some fruits to eat. I would

also thank my two daughters for their sacrifice too. I owed you guys so much time. I promise I

will take you somewhere or play with you more after this.

vi

Table of Contents

LIST OF TABLES ......................................................................................................................... xii

LIST OF FIGURES ...................................................................................................................... xiii

LIST OF SYMBOLS ................................................................................................................... xvii

LIST OF ABBREVIATIONS ....................................................................................................... xix

ABSTRACT .................................................................................................................................. xxi

Chapter 1:

Introduction to capillary electrophoresis: fundamentals and applications .................. 1

1.1 Development of capillary electrophoresis .................................................................................. 1

1.2 Development of capillary electrophoresis instrumentation ........................................................ 1

1.3 Fundamental theory of capillary electrophoresis separation ...................................................... 3

1.3.1 Efficiency ................................................................................................................................ 3

1.3.2 Electroosmotic flow ................................................................................................................ 6

1.3.3 Ohm’s law ............................................................................................................................. 12

1.3.4 Electrophoretic mobility ....................................................................................................... 15

1.3.5 Separation mode.................................................................................................................... 15

1.4 Application of capillary electrophoresis in biopharmaceutical analysis .................................. 27

1.5 List of references...................................................................................................................... 29

Chapter 2: Characterization of glycoprotein erythropoietin by its isoform distribution using

capillary zone electrophoresis ........................................................................................................ 36

2.1 Introduction .............................................................................................................................. 36

2.2 Materials and methods ............................................................................................................. 39

2.2.1 Chemicals and reagents ......................................................................................................... 39

2.2.2 EPO sample preparation........................................................................................................ 39

2.2.3 Formulated epoetin alfa sample preparation ......................................................................... 40

2.2.4 Capillary zone electrophoresis (CZE) ................................................................................... 41

vii

2.2.5 Modified capillary conditioning............................................................................................ 43

2.3 Results and discussion ............................................................................................................. 44

2.3.1 Restoration of the fused silica capillary surface ................................................................... 44

2.3.2 System suitability .................................................................................................................. 48

2.3.3 Characterization and qualification of epoetin alfa secondary standard................................. 49

2.3.4 Precision ................................................................................................................................ 55

2.3.5 Use of duplicate injections for test sample ........................................................................... 57

2.3.6 Use of 2-hour conditioning period on new capillaries .......................................................... 57

2.3.7 Removal of polysorbate 80 from formulated epoetin alfa .................................................... 60

2.4 Conclusions .............................................................................................................................. 62

2.5 List of references...................................................................................................................... 65

Chapter 3: Separation of residual cell culture media components by micellar electrokinetic

chromatography ............................................................................................................................. 68

3.1Introduction ............................................................................................................................... 68

3.2 Materials and methods ............................................................................................................ 70

3.2.1 Chemicals and reagents ......................................................................................................... 70

3.2.2 Standard solutions ................................................................................................................. 72

3.2.3 Sample preparation ............................................................................................................... 72

3.2.4 Capillary electrophoresis....................................................................................................... 73

3.2.5 Capillary conditioning........................................................................................................... 73

3.3 Results and discussion ............................................................................................................. 74

3.3.1 Capillary zone electrophoresis (CZE) vs. micellar electrokinetic chromatography (MEKC)

....................................................................................................................................................... 74

3.3.2 Effect of surfactant concentration ......................................................................................... 78

3.3.3 Effect of pH........................................................................................................................... 81

3.3.4 Detection wavelength............................................................................................................ 81

3.4 Validation of the analytical procedure ..................................................................................... 83

viii

3.4.1Limit of detection (LOD) and limit of quantitation (LOQ) ................................................... 90

3.4.2 Specificity ............................................................................................................................. 97

3.4.3 Linearity and range ............................................................................................................... 97

3.4.4 Accuracy and precision ......................................................................................................... 99

3.5 Concluding remarks ................................................................................................................. 99

3.6 List of references.................................................................................................................... 103

Chapter 4: Characterization of monoclonal antibody using capillary sodium dodecyl sulfate gel

electrophoresis ............................................................................................................................. 107

4.1Introduction ............................................................................................................................. 107

4.2 Materials and methods ........................................................................................................... 111

4.2.1Reagents and solutions ......................................................................................................... 111

4.2.2 Preparation of solutions ...................................................................................................... 112

4.2.3 Preparation of samples ........................................................................................................ 113

4.2.4 Capillary SDS (cSDS) analysis ........................................................................................... 114

4.2.5 Capillary conditioning......................................................................................................... 114

4.3 Results and discussion ........................................................................................................... 115

4.3.1 Effect of sample buffer pH.................................................................................................. 115

4.3.2 Alkylation condition ........................................................................................................... 119

4.3.3 Incubation temperature and time......................................................................................... 119

4.3.4 Reduction conditions........................................................................................................... 123

4.3.5 Characterization of the aglycosylated heavy chain (AGHC) .............................................. 123

4.3.6 Summary of optimized parameters of the cSDS Method.................................................... 126

4.4 Method validation .................................................................................................................. 129

4.4.1 Specificity ........................................................................................................................... 129

4.4.2 Accuracy ............................................................................................................................. 135

4.4.3 Precision (repeatability and intermediate precision) ........................................................... 135

ix

4.4.4 Limit of quantitation (LOQ) ............................................................................................... 138

4.4.5 Linearity and range ............................................................................................................. 144

4.4.6 Sample stability ................................................................................................................... 146

4.5 Concluding remarks ............................................................................................................... 146

4.6 List of references.................................................................................................................... 150

Chapter 5: Optimization of injection length into a capillary for detection sensitivity

enhancement in micellar electrokinetic chromatography............................................................. 157

5.1 Introduction ............................................................................................................................ 157

5.2 Materials and methods ........................................................................................................... 163

5.2.1 Reagents and solutions ........................................................................................................ 163

5.2.2 Capillary electrophoresis (CE) ............................................................................................ 165

5.2.3 Capillary conditioning......................................................................................................... 166

5.3 Results and discussion ........................................................................................................... 166

5.3.1 Injection length vs. retention factor .................................................................................... 166

5.3.2 Injection length vs. efficiency ............................................................................................. 172

5.4 Concluding remarks ............................................................................................................... 177

5.5 List of References .................................................................................................................. 180

Chapter 6: Conclusions and future directions .............................................................................. 184

6.1 Conclusions ............................................................................................................................ 184

6.2 Future directions .................................................................................................................... 186

6.3 List of references.................................................................................................................... 188

Appendix A: UV spectra of the six cell culture media components ............................................ 189

Appendix B: Detection sensitivity comparison of cell culture media components at fixed

wavelength ................................................................................................................................... 195

x

List of Tables

Table 1.1List of parameters that affect EOF in CE [41-42, 30] ..................................................... 13

Table 2.1 Precision of migration times (MTs) and relative migration times (RMTs) for two sets

of analyses (Run-1 and Run-2) based on triplicate injections of each preparation ........................ 50

Table 2.2 Precision of relative peak area (%) for two sets of analyses (Run-1 and Run-2) based

on triplicate injections of each preparation .................................................................................... 51

Table 2.3 System suitability data of the BRP primary standard .................................................... 53

Table 2.4 Precision of relative peak area for Run-3 and Run-4 based on triplicate injections of

each preparation ............................................................................................................................. 56

Table 2.5 Average relative areas (%) of the isoforms in all secondary standard preparations ...... 58

Table 2.6 Average relative areas (%) of the isoforms in all secondary standard preparations for

the evaluation of duplicate injection .............................................................................................. 59

Table 2.7 Precision of relative migration time with 2-hour conditioning vs. 12-hour

conditioning ................................................................................................................................... 61

Table 2.8 Relative area (%) of each isoform of the epoetin alfa secondary standard (EPO Std)

and 2000 (2K) IU/mL F-EPO and 40,000 (40K) IU/mL F-EPO ................................................... 63

Table 2.9 Relative area (percent) of each isoform of the epoetin alfa secondary standard (EPO

Std) and 2000 (2K) IU1/mL F-EPO2 and 40,000 (40K) IU/mL F-EPO........................................ 64

Table 3.1 Limit of detection and limit of quantitation data for hypoxanthine ............................... 91

Table 3.2 Limit of detection and limit of quantitation data for riboflavin ..................................... 92

Table 3.3 Limit of detection and limit of quantitation data for xanthine ....................................... 93

Table 3.4 Limit of detection and limit of quantitation data for mycophenolic acid....................... 94

Table 3.5 Limit of detection and limit of quantitation data for folic acid ...................................... 95

Table 3.6 Limit of detection and limit of quantitation data for nicotinic acid ............................... 96

Table 3.7 Linearity and range data (10-100 μM) ......................................................................... 100

Table 3.8 Accuracy and precision data ........................................................................................ 101

Table 4.1 Area percentage of IgG and Impurity using sample buffers with different pH and

varied ionic strength ..................................................................................................................... 116

Table 4.2 Area percentage of IgG and Impurity using sample buffers with different pH with the

same conductivity ........................................................................................................................ 120

xi

Table 4.3 Optimization of alkylating agent (IAM) concentration ............................................... 122

Table 4.4 Comparison of mAb purity under different incubation conditions for reduced and

non-reduced samples. NA: Not Available ................................................................................... 124

Table 4.5 Effect of reduction conditions on the analysis of reduced mAb .................................. 125

Table 4.6 Spike recovery of PNGase F treated samples .............................................................. 128

Table 4.7 Summary of optimized method parameters ................................................................. 130

Table 4.8 Matrix effects study of non-reduced mAb ................................................................... 134

Table 4.9 Matrix effects study of reduced mAb .......................................................................... 134

Table 4.10 Accuracy of mAb purity under non-reduced conditions ............................................ 136

Table 4.11 Accuracy data for mAb purity under reduced conditions .......................................... 137

Table 4.12 Repeatability and intermediate precision of non-reduced mAb cSDS assay ............. 139

Table 4.13 Repeatability and intermediate precision for reduced mAb cSDS assay ................... 140

Table 4.14 LOQ data for the non-reduced mAb cSDS assay....................................................... 142

Table 4.15 LOQ data for the reduced mAb cSDS assay .............................................................. 143

Table 4.16 Linear regression equations for mAb cSDS assay ..................................................... 145

Table 4.17 Stability data for three freeze and thaw cycles of mAb RRS ..................................... 147

Table 4.18 Stability data for mAb samples prepared at 2-8° C ................................................... 148

Table 5.1 Injection time and calculated injection length (n=3).................................................... 173

Table 5.2 Migration time and calculated retention factors (n=3)................................................. 174

xii

List of Figures

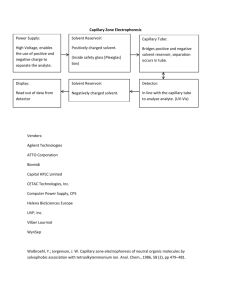

Figure 1.1 Schematic of a typical CE instrument. ©Agilent Technologies, Inc. 2009. Courtesy

of Agilent Technologies, Inc ............................................................................................................ 2

Figure 1.2 Voltage-driven flow in capillary electrophoresis vs. pressure-driven flow in column

chromatography [24]. Reprinted with permission from Physics Today, vol. 54, ©copyright

2001, American Institute of Physics ................................................................................................ 5

Figure 1.3 Formation of zeta potential. The inside wall of the capillary is covered by silanol

groups (Si-OH) that are deprotonated (Si-O-) at pH ≥ 3.0. Si-O- attracts cations to the inside

wall of the capillary. The distribution of charge at the surface is described by the Stern doublelayer model and results in the zeta potential [33]. Reprinted from J. Chromatogr. 1991, 559,

69-80, © Copyright (1991), with permission from Elsevier ............................................................ 8

Figure 1.4 Effect of buffer pH on silanol groups at the surface of fused silica capillary. At low

pH the silanol groups are not ionized. At high pH the silanol groups are ionized ......................... 10

Figure 1.5 Effect of buffer pH on electroosmotic mobility [37]. Reprinted with permission

from J. High Resolut. Chromatogr. Chromatogr. Commun. 1985, 8, 407-11, © Copyright 1985,

John Wiley & Sons, Inc. ................................................................................................................ 11

Figure 1.6 Ohm’s Law Plot. A. Plot of observed current vs. applied voltage for each of three

buffers: 100 mM phosphate, pH 2.5; 100 mM borate, pH 8.3; 100 mM CAPS, pH 11.0. B.

Direct plot of current vs. applied voltage for 100 mM CAPS, pH 11.0. A straight line drawn

from the front edge of the plateau illustrates the ability of the cooling system to dissipate the

heat generated by the current [30, 40]. Reproduced from Handbook of capillary and microchip

electrophoresis and associated microtechniques, © Copyright (2008), with permission from

CRC Press. ..................................................................................................................................... 14

Figure 1.7 Illustration of CZE separation of cations, anions, and neutral compounds .................. 17

Figure 1.8 Illustration of MEKC separation. SDS micelles travel against the EOF but because

of stronger EOF, they are swept to the cathode. Analytes are separated due to their interaction

time with SDS micelles. ................................................................................................................. 20

Figure 1.9 Elution modes in MEKC, where veo, is the electroosmotic velocity; vsc is the velocity

of separation carrier; vs is the analyte velocity. Adapted from reference [48] ............................... 23

Figure 1.10 Illustration of CGE separation. Different sizes of analytes are separated by

electrophoresis under the condition of minimized EOF. vep: electrophoretic velocity. ................. 26

Figure 2.1 Experiment setup of an electronic infusion pump using syringes connected to nonionic detergent (NID) trap cartridges to remove polysorbate 80. The electronic infusion pump

is programmed for different syringe sizes and flow rates, which enables the process to be

automated ....................................................................................................................................... 42

xiii

Figure 2.2 Demonstration of capillary restoration. The peak area and migration time appear

consistent after 36th injection. A: 1st EPO sample injection; B: 36th EPO sample injection.

Peaks 3-8 are six isoforms of EPO................................................................................................. 47

Figure 2.3 Electropherograms of BRP primary standard vs. epoetin alfa secondary standard. A:

BRP primary standard; B: epoetin alfa secondary standard. Isoforms 1-8 were very well

separated. Isoforms 1 and 2 were not present in the epoetin alfa sample ...................................... 52

Figure 3.1 Structures and pKa’s of the cell culture media components. a: folic acid (2.3 (pKa1),

8.3 (pKa2)); b: nicotinic acid (4.85); c: hypoxanthine (8.7); d: xanthine (7.4 (pKa1), 11.1 (pKa2));

e: riboflavin (10.2); f: mycophenolic acid (4.5) [15, 19, 24-26] .................................................... 71

Figure 3.2 Comparison of the separation of the cell culture media components under (A) CZE

and (B) MEKC conditions. Compound identification (10 µM each): 1. hypoxanthine; 2.

riboflavin; 3. xanthine; 4. mycophenolic acid; 5. folic acid; 6. nicotinic acid; and 7. 2naphthalenemethanol (neutral marker). Analytical conditions: 20 mM NaH2PO4, 20 mM

Na2B4O7, pH 9.0, 40 mM SDS (MEKC only), 25 kV, 20°C, absorbance detection at 210 nm.

Fused silica capillary dimensions: 50 µm i.d. x 40 cm (40 cm effective length) ........................... 75

Figure 3.3 Matrix interference under CZE condition. (A) standards under CZE conditions (B)

sample matrix under CZE conditions. 1. hypoxanthine 2. riboflavin 3. xanthine 4.

mycophenolic acid 5. folic acid 6. nicotinic acid. Other conditions as in Figure 3.2 .................... 77

Figure 3.4 Effect of SDS concentration on the separation of the cell culture media components:

(A) 10 mM SDS, (B) 20 mM SDS, (C) 50 mM SDS, (D) 75 mM SDS, and (E) 100 mM SDS.

Compound identification and other conditions as in Figure 3.2 .................................................... 79

Figure 3.5 Effect of SDS concentration on the retention time of the cell culture media

components. Conditions as in Figure 3.2 ...................................................................................... 80

Figure 3.6 Effect of buffer pH on separation (A) At pH 8.0, folic acid and nicotinic acid (5 and

6) co-eluted; (B) At pH 8.5, peak shape of riboflavin (2) and nicotinic acid (6) were distorted.

Other conditions as in Figure 3.2B ................................................................................................ 82

Figure 3.7 Comparison of detection wavelength (210 nm, 220 nm, 254 nm, 275 nm) on the

calibration sensitivity for hypoxanthine. Other conditions as in Figure 3.2 .................................. 84

Figure 3.8 Comparison of detection wavelength (210 nm, 220 nm, 254 nm, 275 nm) on the

calibration sensitivity for riboflavin. Other conditions as in Figure 3.2 ........................................ 85

Figure 3.9 Comparison of detection wavelength (210 nm, 220 nm, 254 nm, 275 nm) on the

calibration sensitivity for xanthine. Other conditions as in Figure 3.2 .......................................... 86

Figure 3.10 Comparison of detection wavelength (210 nm, 220 nm, 254 nm, 275 nm) on the

calibration sensitivity for mycophenolic acid. Other conditions as in Figure 3.2 .......................... 87

Figure 3.11 Comparison of detection wavelength (210 nm, 220 nm, 254 nm, 275 nm) on the

calibration sensitivity for folic acid. Other conditions as in Figure 3.2 ......................................... 88

Figure 3.12 Comparison of detection wavelength (210 nm, 220 nm, 254 nm, 275 nm) on the

calibration sensitivity for nicotinic acid. Other conditions as in Figure 3.2 .................................. 89

xiv

Figure 3.13 Electropherograms of spiked (A) and non-spiked (B) samples from late stage

protein purification process. Conditions as in Figure 3.2 ............................................................. 98

Figure 4.1 Schematic diagram of Immunoglobulin (IgG) [1]. Fab: antigen-binding fragment

generated by proteolysis with papain; Fc: "crystallizable" fragment of generated by proteolysis

with papain. Reproduced with permission from Lehninger Principles of Biochemistry, 5th

edition, ©Copyright (2008) W. H. Freeman and Company ......................................................... 108

Figure 4.2 Effect of sample buffer pH on cSDS separation of non-reduced mAb. Peak

identification: No. 1: Internal standard with molecular weight of 10,000 Dalton; No. 2: largest

impurity peak; No. 3: mAb (IgG). Peaks earlier than No.1 were from sample buffer blank.

Other impurity peaks were not labeled but integrated for total peak areas.

A: 25 mM citrate-phosphate sample buffer at pH 6.5. Relative area (%) of IgG (peak No.3) was

98.3% and relative area of impurity (peak No. 1) was 1.0%;

B: Original Beckman sample buffer (100 mM Tris-HCl, 1.0% SDS, pH 9.0). Relative area (%)

of IgG (peak No.3) was 96.4% and relative area of impurity (peak No. 2) was 2.3%.

Separation conditions: 30 cm x 50 μm bare silica, electrokinetic injection (-5 kV for 15 s),

separation voltage: -15 kV for 35 minutes ................................................................................... 121

Figure 4.3 PNGase F treated reduced mAb vs. non-treated reduced mAb. 1: Light chain; 2:

Aglycosylated heavy chain; 3: Heavy chain A: Reduced mAb not being treated by PNGase F;

B: Reduced mAb treated by PNGase F. Separation conditions: 30 cm x 50 μm bare silica,

electrokinetic injection (-5 kV for 15 s), applied separation voltage: -15 kV for 35 minutes,

buffer: 25 mM citrate-phosphate, 1.0% SDS, pH 6.5 .................................................................. 127

Figure 4.4 Typical electropherogram of system suitability sample. 1.Internal reference standard

(10 kDa); 2. carbonic anyhydrase (31 kDa); 3. bovine serum albumin (66 kDa); 4. βgalactosidase (116 kDa); 5. mAb RRS (148 kDa) Separation conditions as in Figure 4.3 .......... 131

Figure 4.5 Matrix effect of non-reduced mAb. A: water blank; B: formulation buffer; C: mAb

sample. Peak identification 1: internal standard; 2: impurity; 3: mAb (IgG). Other peaks prior

to 1 are from the sample buffer. Separation conditions as in Figure 4.3 ..................................... 132

Figure 4.6 Matrix effect of reduced mAb. A: water blank; B: formulation buffer; C: mAb

sample. Peak identification 1: internal Standard; 2: light chain; 3: heavy chain. Separation

conditions as in Figure 4.3. .......................................................................................................... 133

Figure 5.1 Basis of stacking in CZE using cations as an example. The region containing sample

ions is a low conductivity solution, while the background region is a high conductivity solution.

Upon application of voltage, the low conductivity region will experience a high electric field

compared to the high conductivity background region. Sample ions then move faster in the low

conductivity region than in the higher conductivity region resulting in the reduction of sample

zone or higher sample concentration. [21] ................................................................................... 158

Figure 5.2 Sweeping in a homogenous electric field in MEKC using a negatively charged

micelle as a pseudostationary phase (PSP) and a negligible EOF environment. (A) A longer

than a typical injection of sample zone prepared in a matrix having a conductivity similar to

micellar background electrolyte (BGE). (B) Upon application of a negative voltage, the BGE

enters the sample zone and sweeps (concentrates) the analyte molecules. (C) The final swept

zone is formed when the BGE completely fills the sample zone. [22] ........................................ 159

xv

Figure 5.3 Structures of the studied compounds: (a) phenyl methyl ketone (acetophenone); (b)

phenyl ethyl ketone (propiophenone); (c) phenyl propyl ketone (butyrophenone)...................... 164

Figure 5.4 Separation of swept zone in a diluted pseudostationary phase (PSP) environment.

Explanation is in the text.............................................................................................................. 169

⎛ l inj

⎜l −l

⎝ eff inj

Figure 5.5 Plot of log (1/k) versus log⎜

⎞

⎟ with eight data points corresponding to

⎟

⎠

injection times of 5-100 seconds .................................................................................................. 175

⎛ l inj

⎜l −l

⎝ eff inj

Figure 5.6 Plot of log(1/k) versus log⎜

⎞

⎟ with five data points corresponding to

⎟

⎠

injection times of 20-50 seconds .................................................................................................. 176

Figure 5.6 Electropherograms of 50 s injection (A) vs. 100 s injection (B). Analyte

identification: (1) acetophenone; (2) propiophenone; (3) butyrophenone. Analytical conditions:

50 mM phosphate, 50 mM sodium dodecyl sulfate, pH 2.0, -25 kV, 210 nm, 20°C, 72 cm x 50

µm capillary . Analyte concentrations: 40 µM (A); 20 µM (B)................................................... 178

Figure 5.7 Plots of plate number vs. injection time. Injection time of 35 seconds gives highest

plate number for butyrophenone and acceptable plate number for acetophenone ....................... 179

Figure A1. UV spectrum of hypoxanthine with λmax = 200 nm. Solvent: 20 mM NaH2PO4, 20

mM Na2B4O7, 40 mM SDS, pH 9.0. Analyte concentration: 0.1 mM. Collected on line using a

photodiode array detector with a 50 μm i.d. fused silica capillary. ............................................. 189

Figure A2. UV spectrum of riboflavin with λmax = 270 nm. Solvent and solute concentration as

in Figure A1. ................................................................................................................................ 190

Figure A3. UV spectrum of xanthine with λmax = 200 nm. Solvent and solute concentration as

in Figure A1. ................................................................................................................................ 191

Figure A4. UV spectrum of mycophenolic acid with λmax = 225 nm. Solvent and solute

concentration as in Figure A1. ..................................................................................................... 192

Figure A5. UV spectrum of folic acid with λmax = 190 nm. Solvent and solute concentration as

in Figure A1. ................................................................................................................................ 193

Figure A6. UV spectrum of nicotinic acid with λmax = 190 nm. Solvent and solute concentration

as in Figure A1. ............................................................................................................................ 194

Figure B1. Comparison of analyte absorbance at wavelength of 210 nm.................................... 195

Figure B2. Comparison of analyte absorbance at wavelength of 222 nm.................................... 196

Figure B3. Comparison of analyte absorbance at wavelength of 254 nm.................................... 197

xvi

Figure B4. Comparison of analyte absorbance at wavelength of 275 nm.................................... 198

xvii

List of symbols

α

Δ

ΔP

Δv

Δμep

ε0

εr

η

σ

σ2

μeo

μep

μep,avg

μnet

ζ

ζa

ϕ

δ

λmax

AC

Cmic

Cs

D

e

E

k

k1

k2

selectivity factor

distance between two zones

pressure across the capillary

difference in velocities

difference in electrophoretic mobilities of the two zones

permittivity of a vacuum

relative permittivity of the buffer

viscosity

standard deviation of residue

variance or standard deviation squared

electroosmotic mobility

electrophoretic mobility

average electrophoretic mobility of the analytes

net mobility

zeta potential

zeta potential of analyte

phase ratio

double layer thickness

absorbance wavelength at maximum intensity

Isoform of EPO anion

sample concentration

micelle concentration in the running buffer

micelle concentration in the separation zone

diffusion coefficient

total excess charge in solution per unit area

electric field

retention factor

retention factor, peak #1

retention factor, peak #2

k

average retention factor

conductivity of running buffer

conductivity of sample buffer

length of the capillary

effective capillary length (inlet to the detector)

total capillary length

injection length

swept length

molar concentration

efficiency or number of theoretical plates

number of replicates

partition coefficient

injection amount

coefficient of determination

capillary inner radius

resolution

migration time of a neutral solute

migration time of the micelle

ka

kb

L

Leff

Ltot

linj

lsweep

M

N

n

P

Qinj

r2

r

Rs

t0

tmc

xviii

tmob

tpsp

tR

tsc

vavg

vep

V

Vsc

Vaq

Vmob

Wavg

residence time in mobile phase

migration time of the pseudostationary phase

migration time of the solute

residence time with the separation carrier

average velocity

electrophoretic velocity

voltage

volume of separation carrier

volume of aqueous phase

volume of mobile phase

average width of the two zones measured via tangents to the baseline

xix

List of abbreviations

ACS

AGHC

BGE

BRP

BSA

CAPS

CE

CGE

CIEF

CITP

CMC

cSDS

CZE

DAB

EKC

EOF

EPO

Fab

FB

Fc

F-EPO

GC

H3PO4

HAc

HC

HCl

HPLC

IAA

IAM

IgG

i.d.

IU

LC

mAb

2-ME

MEKC

MeOH

NaHAc

NaOH

MT

NEM

NID

Ph. Eur.

PNGase F

PS80

PSP

QC

RMT

American Chemical Society

aglycosylated heavy chain

background electrolyte

biological reference preparation

bovine serum albumin

N-cyclohexyl-3-aminopropanesulfonic acid

capillary electrophoresis

capillary gel electrophoresis

capillary isoelectric focusing

capillary isotachophoresis

critical micelle concentration

capillary sodium dodecyl sulfate gel electrophoreis

capillary zone electrophoresis

1, 4-diaminobutane

electrokinetic chromatography

electroosmotic flow

erythropoietin

antigen binding fragment

formulated bulk

crystallizable fragment

formulated erythropoietin

gas chromatography

phosphoric acid

acetic acid

heavy chain

hydrochloric acid

high performance liquid chromatography

iodoacetic acid

iodoacetamide

immunoglobulin G

inner diameter

International Units

light chain

monoclonal antibody

2-mercaptoethanol

micellar electrokinetic chromatography

methanol

sodium acetate

sodium hydroxide

migration time

N-ethylmaleimide

non-ionic detergent

The European Pharmacopoeia

Peptide N-Glycanase

polysorbate 80

pseudostationary phase

quality control

relative migration time

xx

RRS

RSD

SDS

SDS-PAGE

SEC

TLR

Tris-base

Tris-HCl

Tricine

UV

research reference standard

relative standard deviation

sodium dodecyl sulfate

sodium dodecyl sulfate-polyacrylamide gel electrophoresis

size exclusion chromatography

toll-like receptor

tris-(hydroxymethyl)aminomethane

tris-(hydroxymethyl)aminomethane hydrochloride

N-tris-(hydroxymethyl)methylglycine

ultraviolet

xxi

Abstract

Quantitative Biopharmaceutical Applications of Capillary Electrophoresis

Junge Zhang

Dr. Joe P. Foley

Various modes of capillary electrophoresis offer numerous possibilities for biopharmaceutical

analysis. Chapter 2 studied capillary zone electrophoresis (CZE) for characterization of

glycoprotein erythropoietin by its isoform distribution. The CZE method for identification of

recombinant human erythropoietin described in the European Pharmacopoeia has shown poor

reproducibility. In this study, it was found that the root cause of the irreproducibility was due to

inadequate capillary conditioning. The method was optimized to make it more robust and

suitable for quality control laboratory for analysis of epoetin alfa. Further, a procedure for

removal of polysorbate 80 from formulated epoetin alfa was developed, allowing the material

to be analyzed using the modified CZE method.

Chapter 3 describes a micellar electrokinetic chromatography (MEKC) method for the

determination of residual cell culture media components including folic acid, hypoxanthine,

mycophenolic acid, nicotinic acid, riboflavin, and xanthine. Acceptable limits of detection and

quantitation were obtained. The MEKC method was compared to the corresponding CZE

method using the same running buffer containing no sodium dodecyl sulfate (SDS). The effect

of SDS concentration on separation, the pH of the running buffer, and the detection wavelength

were studied and optimal MEKC conditions were established.

Chapter 4 describes a capillary SDS gel electrophoresis method for purity and impurity

analysis of monoclonal antibodies. The study investigated the effect of sample buffer pH,

incubation temperature and duration, alkylation conditions with iodoacetamide, and reduction

conditions with 2-mercaptoethanol. It was observed that the sample buffer at slight acidic

xxii

conditions (pH 5.5-6.5) greatly decreased thermally induced fragmentation of non-reduced

CNTO3157. As such, a citrate-phosphate buffer at pH 6.5 was used for sample preparation to

replace the commonly used Beckman sample buffer (pH 9.0).

Chapter 5 details an investigation of the effect of sample injection length on efficiency and

detection sensitivity enhancement in MEKC using the sweeping technique under conditions of

suppressed electroosmotic flow. The relationship between injection length and retention factor

was derived and experimentally confirmed. A method for predicting the optimal injection

length for a given analyte was developed.

1

Chapter 1: Introduction to capillary electrophoresis: fundamentals and

applications

1.1 Development of capillary electrophoresis

Capillary electrophoresis (CE) is a separation technique that employs narrow-bore

capillaries to perform electrophoresis in free solution or nonconductive medium,

such as a gel [1]. CE was first introduced in 1967 by Hjerten [2] and further

developed and improved by Mikkers et al. [3] and Jorgenson and Lukacs [4] by

reducing capillary diameters that achieved high column efficiencies. Other notable

developments after the introduction of CE include transition from the slab-gel to the

capillary format in 1980s [5-8] for protein and DNA separations, the use of micellar

solution as a medium for separation of neutral and charged species [9], and the

breakthrough of on-line concentration phenomenon for trace analysis [10-11].

These developments led to a variety of separation modes including capillary zone

electrophoresis (CZE), capillary gel electrophoresis (CGE), and micellar

electrophoresis (MEKC). Different separation modes greatly enhanced the

versatility of CE technique and expanded the horizon of its applications [12-18].

1.2 Development of capillary electrophoresis instrumentation

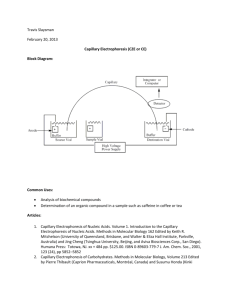

A schematic presentation of a CE system is given in Figure 1.1. Analytes are

separated in a small diameter capillary filled with running buffer. Samples are

introduced by either hydrodynamic (pressure or vacuum) or electrokinetic (positive

or negative voltage) techniques. Upon application of an electric field, compounds

are separated due to their differences in mobility. On-capillary detection

2

Figure 1.1 Schematic of a typical CE instrument. ©Agilent Technologies, Inc. 2009,

Courtesy of Agilent Technologies, Inc.

3

is normally used. The detector signal is collected and processed through a

computerized data system.

Fused silica with polyimide covering in various lengths up to 100 cm and 25-100

µm inner diameters are normally used as separation capillaries. Fused silica is

transparent to UV light, flexible when coated with polymer, and inexpensive,

making it an ideal material for CE capillaries [19] . The commonly available

detectors include absorbance, fluorescence, conductivity, or a mass spectrometer.

Most high voltage supplies are restricted to 30 kV due to the limitation of electrical

breakdown of insulators and atmosphere [20].

A high level of automation and safety features are the main considerations for

instrumentation development. In 1988, the first commercial CE instrument was

made available for analysts [21] and followed by numerous models from several

leading scientific instrument companies. The recent improvements in CE

instrumentation bring unprecedented separation power that resolves many analytical

challenges for CE applications.

1.3 Fundamental theory of capillary electrophoresis separation

1.3.1

Efficiency

Most chromatographic separation techniques, such as high performance liquid

chromatography (HPLC) and gas chromatography (GC), are pressure-driven

separations. CE is a voltage-driven analytical separation technique in which charged

or neutral analytes move with different mobility under the influence of an electric

4

field. The major difference between pressure-driven and voltage-driven separations

lies in the bulk flow profile due to the different separation mechanisms. In open

tubular pressure-driven systems, the frictional forces of the mobile phase interacting

at the walls of the tubing result in radially symmetric velocity gradients throughout

the tube. As a result, the fluid velocity is greatest at the middle of the tube and

approaches zero near the walls. A consequence of this pressure-driven flow is a

parabolic radial velocity profile, also known as a laminar profile, which attributes to

band broadening [22].

In voltage driven system, the flow is generated uniformly down the entire length of

the capillary. There is no pressure drop in CE, and the radial flow profile is uniform

across the capillary except very close to the wall, where the flow rate approaches

zero [23]. Figure 1.2 shows a comparison of a pressure-driven flow profile in

column chromatography vs. a voltage driven flow profile in capillary

electrophoresis [24]. One advantage of flat flow over laminar flow is that it

eliminates the contributions from eddy dispersion to the column plate height [25,

19]. The separation efficiency (N) in CE can be determined, assuming that

longitudinal diffusion is the only source of band broadening [26]:

N=

μ netV ⎛ Leff ⎞

⎜

⎟=

2 D ⎜⎝ Ltot ⎟⎠

μ net ELeff

2D

(1.1)

where D is the diffusion coefficient of an ion in electrolyte solution; µnet is net

5

Figure 1.2 Voltage-driven flow in capillary electrophoresis vs. pressure-driven flow

in column chromatography [24]. Reprinted with permission from Physics Today,

vol. 54, ©copyright 2001, American Institute of Physics.

6

(apparent) electrophoretic mobility of an ion; V is the voltage applied to the

capillary; Leff is the effective capillary length (from inlet to the detection window);

Ltot is the total capillary length; E is the electric field . As can be seen from the

equation, the separation efficiency can be enhanced by higher electric field. A

shorter capillary can be used to reduce analysis time without compromising the

column efficiency. However, in practice, there are other sources that cause band

broadening in CE, including Joule heating, capillary wall binding, and finite width

of injection, which result in lower than calculated efficiency [27-29]. These factors

can be controlled by proper column cooling, capillary conditioning, short injection

plug, etc.

1.3.2

Electroosmotic flow

The net mobility of an analyte is given by the equation [30]:

μ net = μ eo + μ ep

(1.2)

where µeo is the electroosmotic mobility and µep is the electrophoretic mobility.

The electroosmotic mobility (m2/[Vs]) is the constant of proportionality between

electroosmotic velocity and electric field (V/m). Generally speaking, electroosmotic

flow (EOF) is the motion of an electrolyte solution driven by a combination of a

charge imbalance at a solid-liquid interface and an electrical field in that liquid [31,

19]. In capillary electrophoresis, EOF is induced by the electric field in the parallel

direction with the capillary wall on the free electric charge in the diffuse part of the

electric double layer at the solid–liquid interface inside the capillary [32]. The

origin of EOF is described below.

7

The inner surface of a fused silica capillary has ionizable silanol groups (Si-OH).

These silanol groups readily dissociate (Si-O-) when in contact with an electrolyte

solution with a pH ≥ 3, producing a capillary wall with an intrinsic negative charge.

At the silica surface, a slight excess of positively charged ions from the buffer

solution are attracted to the negatively charged capillary wall, forming an electrical

double layer and a potential difference, called zeta potential, denoted by ζ, as

depicted in Figure 1.3 [33]. The zeta potential is described by Stern’s model in

many CE text books [1, 34, 30]. Stern’s model for an electrical double layer is

composed of a compact layer of adsorbed ions (Stern layer) and a diffuse layer. The

thickness of the electrical double layer is normally about 10 nm [19]. The zeta

potential decreases exponentially with increasing distance from the capillary wall

surface. Zeta potential is expressed by:

ζ =

4πδe

ε

(1.3)

where ε is the buffer’s dielectric constant; e is total excess charge in solution per

unit area; δ is the double layer thickness or Debye ionic radius. When a voltage is

applied across the capillary, cations in the diffuse layer are forced to migrate

towards the cathode, carrying the bulk solution with them. The result is a net flow in

the direction of the cathode, with an electroosmotic mobility described as [1]:

μ eo =

εζ

4πη

where η is the viscosity of the buffer in the electrical double layer.

(1.4)

8

Figure 1.3 Formation of zeta potential. The inside wall of the capillary is covered

by silanol groups (Si-OH) that are deprotonated (Si-O-) at pH ≥ 3. Si-O- attracts

cations to the inside wall of the capillary. The distribution of charge at the surface is

described by the Stern double-layer model and results in the zeta potential [33].

Reprinted from J. Chromatogr. 1991, 559, 69-80, © Copyright (1991), with

permission from Elsevier.

9

EOF is a very important parameter in CE. On the one hand, it provides separation

of ions with positive and negative charges and on the other hand, it is a major

contributor to migration time variability form run to run if it is not properly

controlled. There are many factors that affect EOF, including buffer pH and

concentration, temperature, viscosity, capillary surface, field strength, and buffer

additives such as surfactants and organic modifiers. Understanding how these

factors affect the EOF is critical for CE method development.

For fused silica, at high pH (> 9) the silanol groups are mostly ionized and produce

a high zeta potential and a dense electrical double layer, so the EOF is high [35]. At

low pH (< 3), the silanol groups are hardly ionized and the zeta potential is low, so

is the EOF [36]. Figures 1.4 illustrates the effect of buffer pH on silanol groups.

Figure 1.5 depicts the effect of buffer pH on electroosmotic mobility.

Buffer ionic strength also affects EOF. As ionic strength increases, the double layer

becomes compressed, which results in a decreased zeta potential and lower EOF.

This can be seen from equation (1.3) as well. Normally a high ionic strength buffer

is preferred to suppress ion exchange effect between the charged analyte ions and

ionized silanol groups on the capillary wall. However, a high buffer ionic strength

will generate high current and results in substantial Joule heating that the capillary

cooling system cannot handle. In addition, Joule heating can cause band broadening

and reduce resolution. Manipulation of EOF by buffer alone (pH and ionic strength)

is difficult because some other factors such as the contributions of

10

Figure 1.4 Effect of buffer pH on silanol groups at the surface of fused silica

capillary. At low pH the silanol groups are not ionized. At high pH the silanol

groups are ionized.

11

Figure 1.5 Effect of buffer pH on electroosmotic mobility [37]. Reprinted with

permission from J. High Resolut. Chromatogr. Chromatogr. Commun. 1985, 8,

407-11, © Copyright 1985, John Wiley & Sons, Inc.

12

specific adsorption, the competition of different ions for binding sites, and effects

like secondary adsorption are not yet fully understood [36]. Other factors that affect

EOF are summarized in Table 1.1.

1.3.3

Ohm’s law

Because buffer concentration has both positive and negative effect on CE

separation, there is a high demand for finding an optimized buffer concentration for

CE method development. Nelson et al. described a simple method, termed “Ohm’s

Law Plot”, that can easily determine the optimal buffer concentration and the

highest voltage that can be used with this particular buffer system [38]. In this

method, the applied voltage is varied over short intervals across a capillary that is

filled with buffer at a set temperature, and the current is recorded at each voltage. A

graph is made of current vs. voltage. The plot should be linear if Joule heat is

effectively dissipated. Whenever the curve starts showing a positive deviation from

linearity, the cooling system has reached its capacity. Operating on the linear

portion of the curve will give high capillary efficiency. Generally for an optimal

separation, the heat should not exceed 1.5 W/m [39]. Figure 1.6 shows a typical

Ohm’s law plot with 100 mM concentrations of each of these three buffers:

phosphate pH 2.5, borate pH 8.3, and N-cyclohexyl-3-aminopropanesulfonic acid

(CAPS) titrated by NaOH to pH 11.0 [40]. At every applied voltage above, the

current is lowest with borate buffer and significantly higher with phosphate and

CAPS. At 25 kV, the calculated power for borate, phosphate, and CAPS is 0.58,

10.07, and 5.88 W/m, respectively. From this plot, it demonstrates that phosphate

13

Table 1.1 List of parameters that affect EOF in CE [41-42, 30]

Parameter

Buffer pH

Result

EOF increases at high

pH and decrease at low

pH

Comments

1.

2.

1.

Buffer ionic strength

Decreases zeta potential

and EOF when increased

Temperature

Changes viscosity 2-3%

per °C

Organic modifier

Changes zeta potential

and viscosity (usually

decreases EOF)

Electric field

Proportional change in

EOF

2.

1.

1.

2.

1.

2.

1.

Surfactant

Absorbs to capillary wall

via hydrophobic and/or

ionic interactions

2.

3.

Most convenient and useful

method to change EOF

May change charge or structure

of analyte

High ionic strength generates

high current and possible Joule

heating

Low ionic strength problematic

for sample adsorption

Often useful since temperature

is controlled automatically by

instrument

Complex changes, effect most

easily determined

experimentally

May change selectivity

Efficiency and resolution may

decrease when lowered

Joule heating may result when

increased

Anionic surfactants can

increase EOF

Cationic surfactant can

decrease or reverse EOF

Can significantly alter

selectivity

14

Phosphate

CAPS

Borate

Figure 1.6 Ohm’s Law Plot. A. Plot of observed current vs. applied voltage for each

of three buffers: 100 mM phosphate, pH 2.5; 100 mM borate, pH 8.3; 100 mM

CAPS, pH 11.0. B. Direct plot of current vs. applied voltage for 100 mM CAPS, pH

11.0. A straight line drawn from the front edge of the plateau illustrates the ability

of the cooling system to dissipate the heat generated by the current [30, 40].

Reproduced from Handbook of capillary and microchip electrophoresis and

associated microtechniques, © Copyright (2008), with permission from CRC Press.

15

and CAPS buffer should not be used at voltage above 10 kV and 15 kV,

respectively. It also shows that for 100 mM borate buffer, a voltage of up to 30 kV

can be used.

1.3.4

Electrophoretic mobility

In equation 1.1, besides electroosmotic mobility, the electrophoretic mobility

contributes to the net mobility of the analytes too. Electrophoretic mobility (µep) is

given by [1]:

⎛ 2 ⎞ ε 0ε r ζ a

⎝3⎠ η

μ ep = ⎜ ⎟

(1.5)

where ε0 is the permittivity of a vacuum; εr is the relative permittivity of the buffer

(εr=ε0εbuffer/4π); ζa is the zeta potential of the analyte; η is the viscosity of the buffer.

From equation (1.2), the apparent mobility of an analyte is not directly related to its

electrophoretic mobility, but to the combination of both its electrophoretic mobility

and the EOF mobility. In CE, if the buffer pH is high (pH ≥ 9.0) and a positive

voltage is applied to the inlet, the EOF will be in a direction of inlet to detector.

Because the electrophoretic mobility of anions will be slower than the EOF, the net

mobility of anions, cations, and neutral analytes will migrate towards the detector

regardless of their charge. The migration order will be cations, neutrals, and anions.

1.3.5

Separation modes

16

Separation mode in HPLC is determined by column stationary phase and mobile

phase. Separation mode in CE is determined only by buffer. In CE, one type of

capillary can be used for different modes of separations.

1.3.5.1 Capillary zone electrophoresis (CZE)

CZE is the most commonly used mode of separation in CE. Under high EOF

conditions, CZE is able to separate both cations and anions in the same run. The

separation in CZE is based on the differences in analytes’ electrophoretic mobilities

that result in different velocities of migration of ionic species [43].

Figure 1.7 illustrates a CZE separation. The EOF in uncoated fused silica capillaries

is usually significantly greater than the electrophoretic mobility of the individual

ions in the injected sample. Upon the application of an electric field, cations are

migrating towards the cathode and their speed is augmented by the EOF. Anions,

although electrophoretically migrating towards the anode, are swept towards the

cathode with the bulk flow of the running buffer. Under these conditions, cations

with the highest charge/frictional drag migrate first, followed by cations with lower

charge/frictional drag. All the neutral compounds migrate unresolved because their

charge is zero. Anions with lower charge/frictional drag ratio migrate earlier than

those with greater charge/frictional drag ratio. The anions with the greatest

electrophoretic mobilities migrate last. One important point to note is that it is

possible to change the charge of many ions by adjusting pH of the running buffer to

alter their ionization and hence electrophoretic mobility. The resolution (Rs) in CZE

is governed by the following relationships [44-45]:

17

EOF

+

Anion -2

Cation -2

Cation -1

0

Cation -3

Neutral

Anion -1

tm (min)

Figure 1.7 Illustration of CZE separations of cations, anions, and neutral

compounds.

18

Rs =

Δ

N ⎛⎜ Δv

=

4 ⎜⎝ v avg

Wavg

⎞

⎛

Δμ ep

⎟= N ⎜

⎟

4 ⎜⎝ μ ep ,avg + μ eo

⎠

⎞

⎟

⎟

⎠

(1.6)

Replacing N with equation (1.1), Rs can be written as:

⎛

⎞

V

⎛ 1 ⎞

⎟

Rs = ⎜

⎟(Δμ ep )⎜

⎜ D( μ + μ ) ⎟

⎝4 2⎠

ep

eo ⎠

⎝

1

2

(1.7)

where Δ is the distance between two zones; Wavg is the average width of the two

zones measured via tangents to the baseline; Δv and Δµep are the differences in the

velocities and electrophoretic mobilities of the two zones, respectively; vavg and

µep, avg are the average velocity and electrophoretic mobility of two zones; V is the

applied voltage; N is the theoretical plate number; and D is the diffusion coefficient

of one analyte.

Equation (1.7) shows that increasing voltage will improve resolution but only by its

square root. However, if Ohm’s law permits, the highest voltage should be used to

obtain fastest separation. EOF plays a major role in resolution. As can be seen from

the equation, the highest resolution will be attained when the EOF is approaching

the average electrophoretic mobility of the analytes but in the opposite direction of

analytes (µeo ≈ -µep,avg). This will result in almost infinite separation time. It is

obvious that higher resolution will also be attained when the difference in analyte

electrophoretic mobility is large. Other main parameters affecting CZE resolution

are capillary dimension and nature, separation electrolyte composition (pH, ionic

strength, salt nature, additives), and capillary temperature. Recently, more

methodologies have been applied to enhance resolution using non-aqueous and

19

hydro-organic electrolytes, isoelectric buffers and additives such as ionic liquids

[46-47].

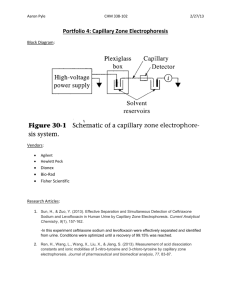

1.3.5.2 Micellar electrokinetic chromatography (MEKC)

MEKC is derived from electrokinetic chromatography (EKC). EKC is a separation

technique based on a combination of electrophoresis and interactions of the analytes

with additives (e.g. surfactants) that form a dispersed secondary phase moving at a

different velocity [48], also called a pseudostationary phase or separation carrier

[49-50]. MEKC is a special case of EKC, in which the secondary phase is a micellar

dispersed phase in the capillary. MEKC can separate neutral as well as charged

analytes. In MEKC, surfactants are added to the running buffer to form micelles.

The separation of neutral analytes is based on the hydrophobic interaction of solutes

with the micelles. The stronger the interaction, the longer the solutes migrate with

the micelle. The selectivity of MEKC can be controlled by the choice of surfactant

and also by the addition of modifiers to the buffer.

Figure 1.8 shows an illustration of a MEKC separation using sodium dodecyl

sulfate (SDS) as a pseudostationary phase. SDS is a widely used anionic surfactant.

One end of SDS is the hydrophilic sulfate group, and the other end is the

hydrophobic C12 group. When a surfactant is in solution at a concentration higher

than its critical micelle concentration, CMC, it forms micelles which are

aggregation of individual surfactant molecules. Micelles have a three-

20

SDS

EOF

+

tR1

t0

tR2

tR3

-

tmc

tm

Figure 1.8 Illustration of MEKC separation. SDS micelles travel against the EOF

but because of stronger EOF, they are swept to the cathode. Analytes are separated

due to their interaction time with SDS micelles.

21

dimensional structure with the hydrophobic moieties of the surfactant in the interior

and the charged moieties at the exterior . When a hydrophobic compound is added

to an aqueous solution that contains micelles, it partitions into the hydrophobic

portions of the micelles. As a result, the analytes are maintained in the solution.

MEKC can separate both neutral and ionic compounds.

As shown in Figure 1.8, the analyte migration order in MEKC is different than

CZE. In MEKC, hydrophilic water soluble analytes do not partition into the

micelles. They are carried through the capillary at the rate of the EOF and are the

first to migrate at t0. The hydrophobic analytes that are totally solubilized by the

micelles spend all of the time in the micelles, and are carried through the capillary

at the same rate as the micelles and elute last at tmc. Analytes that spend part of their

time in the micelles migrate between t0 and tmc.

Unlike chromatography, the pseudostationary phase in MEKC has an effective

electrophoretic mobility due to its charge property. The employment of a

pseudostationary phase changes the dynamics of the analyte zone. The analyte

velocity in MEKC is expressed by [48]:

vs =

t mob

t rsc

1

k

v mob +

v sc =

v mob +

v sc

t mob + t rsc

t mob + t rsc

k +1

k +1

(1.8)

where tmob is the residence time in the mobile phase; trsc is the residence time with

the separation carrier; vsc is the observed velocity of the separation carrier; vmob is

the velocity of mobile phase (EOF) and k is the retention factor (nsc/nmob), where nsc

22

and nmob are the number of moles of solute in the separation carrier and mobile

phase, respectively.

Like chromatography, the retention factor (k) in MEKC is defined as residence time

in the separation carrier divided by residence time in the surrounding liquid [48].

The separation process is due to the distribution between two distinct phases having

two different observed mobilities [48]:

k = ϕP =

Vsc

P

Vmob

(1.9)

where ϕ is phase ratio; P is partition coefficient; Vsc is volume of separation carrier;

and Vmob is volume of surrounding mobile phase.

The retention factor and resolution in MEKC are more complex than in CZE. There

are three elution modes in MEKC, namely, normal mode, restricted mode, and

reversed mode, as shown in Figure 1.9. In each mode, the retention factor is

calculated differently.

Normal elution mode:

k=

t s − t0

t 0 (1 − t s / t sc )

k=

ts + t0

t 0 (t s t sc − 1)

(1.11)

ts − t0

t 0 (t s t sc + 1)

(1.12)

Reversed elution mode:

k=

Restricted elution mode:

(1.10)

23

veo

vsc

vs

(A) Normal Elution Mode

veo

vsc

vs

(B) Restricted Elution Mode

veo

vsc

vs

(C) Reversed Elution Mode

Figure 1.9 Elution modes in MEKC, where veo, is the electroosmotic velocity; vsc is

the velocity of separation carrier; vs is the analyte velocity. Adapted from reference

[48].

24

Corresponding to each elution mode, the resolution is also expressed differently

[51].

Normal elution mode:

Rs =

N ⎛ α − 1 ⎞⎛ k ⎞⎛ 1 − t 0 / t sc

⎟⎜

⎜

⎟⎜

4 ⎝ α ⎠⎜⎝ k + 1 ⎟⎠⎜⎝ 1 + (t 0 / t sc )k

⎞

⎟⎟

⎠

(1.13)

Reversed elution mode:

Rs =

N ⎛ α − 1 ⎞⎛ k ⎞⎛ 1 + t 0 / t sc ⎞

⎟

⎟⎜

⎜

⎟⎜

4 ⎝ α ⎠⎜⎝ k + 1 ⎟⎠⎜⎝ (t 0 / t sc )k − 1 ⎟⎠

(1.14)

Restricted elution mode:

Rs =

N ⎛ α − 1 ⎞⎛ k ⎞⎛ 1 + t 0 / t sc

⎟⎜

⎜

⎟⎜

4 ⎝ α ⎠⎜⎝ k + 1 ⎟⎠⎜⎝ 1 − (t 0 / t sc )k

⎞

⎟⎟

⎠

(1.15)

where α is selectivity factor (k2/k1); k is the average retention factor.

From above equations, in normal elution mode, the time window for a neutral

compound to elute is between t0 and tsc and the time ratio t0/tsc has a significant

impact on resolution.

Foley discovered that for neutral solutes in the normal elution mode, the highest

resolution can be achieved when kOPT ( Rs ) =

t sc / t 0 [52]; for charged solutes, the

_

highest resolution occurs when k OPT ( Rs ) = t mc t 0 (1 + μ r ) , where µr is the relative

electrophoretic mobility (µr =µep/µeo), i.e., the electrophoretic mobility of an analyte

(positive, zero, or negative) relative to the coefficient of electroosmotic flow [53].

In restricted and reversed modes, there is no time window for a neutral analyte to

25

elute because with the increase of retention factor, resolution reaches infinity. Even

for very low selectivity, high resolution can be obtained. However, the migration

time could be very long.

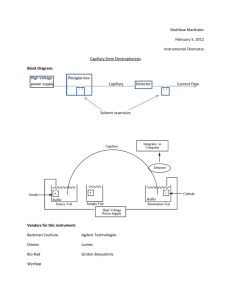

1.3.5.3

Capillary gel electrophoresis (CGE)

CGE is the capillary format of traditional slab-gel electrophoresis and is used for the

size-based separation of biological macromolecules such as oligonucleotides, DNA

restriction fragments and proteins [54]. The basic difference between traditional

slab gel electrophoresis and capillary gel electrophoresis is the use of narrow bore,

fused-silica columns filled with buffer and a sieving medium [53]. Figure 1.10

shows an illustration of a CGE separation. The capillaries are either wall coated or

chemically bonded to minimize electroosmotic flow so that gel will not be extruded

from the capillary [1]. Capillaries are filled with cross-linked or linear polymerized

gels, usually polyacrylamide [7]. Samples are introduced into the capillaries

preferably by electrokinetic injection, a method that usually results in sharp peaks

due to stacking. Analytes move through the capillary by electrophoresis and are

separated by the sieving mechanism of the gel.

Several mechanisms have been described for the size separation [23]. One of them

is Ogsten model, which treats a molecule as a non-deformable sphere with the

migration velocity determined by an analyte’s mobility modified by the probability

of an encounter with a restricting pore [55, 21]. The separation of analytes with a

radius of gyration less than or equal to the average pore size can be explained by

this model. CGE can be performed using either crosslinked or linear polymers.

26

Capillary Gel Electrophoresis (CGE)

+

vep

-

Figure 1.10 Illustration of CGE separation. Different sizes of analytes are separated

by electrophoresis under the condition of minimized EOF. vep: electrophoretic

velocity.

27

Crosslinked polyamide gel can be prepared in situ [56]. The size and distribution of

the pores for a crosslinked gel are determined by the distribution of crosslinks, the

distance between the crosslinks, and the liquid present in the gel. The pore structure

is responsible for separation of analytes. The pore size is controlled by the total

amount of acrylamide (T%) and the amount of crosslinker (C%). T% and C% are

calculated by equation (1.16) and (1.17), respectively [21].

T% =

C% =

acrylamide ( g ) + bisacrylam ide ( g )

100 mL

(1.16)

bisacrylam ide ( g )

× 100

bisacrylam ide ( g ) + acrylamide ( g )

(1.17)

Non-cross-linked, linear polymer networks are also used in CGE. A linear polymer

network is not attached to the inside wall of the capillary and very flexible. The

pore sizes of these network is defined by dynamic interactions between the polymer

chains and can be varied by changing capillary temperature, separation voltage, salt

concentration, or pH. Linear polymer gels are not heat sensitive and are easily

replaceable by pressure between the runs. Such gels permit both electrokinetic and

hydrodynamic injections. Linear polyacrylamide gels were introduced first into

coated capillary columns and applied to the separation of double-stranded DNA

fragments containing as many as several thousand base pairs [57].

1.4

Application of Capillary Electrophoresis in biopharmaceutical analysis

28

CE has demonstrated to be a complementary alternative to chromatographic

techniques in a broad range of applications such as environmental, clinical, forensic,

biomedical, pharmaceutical, and biopharmaceutical analysis. Various modes of CE

offer numerous possibilities for biopharmaceutical analysis including glycosylated

therapeutic proteins, monoclonal antibodies, and pharmaceutical and

biopharmaceutical impurities [58-59]. CZE has been used for analytes as diverse as

inorganic ions, organic pharmaceutical drugs, and proteins as long as there are

differences in charge-to-frictional drag ratios among the analyte species [60].

MEKC has been used for analysis of water-soluble neutral compounds, weak acids