T o p i c S h e e t : Concept Development

Page 1 of 4

Concept Development

D e f i n i n g a lt e r n at e p r o duc t c o n c e p t s , i n v e s t i g at i n g p r o duc t f e a s i b i l i t y,

a n d s e l e c t i n g t h e b e s t c a n d i d at e s

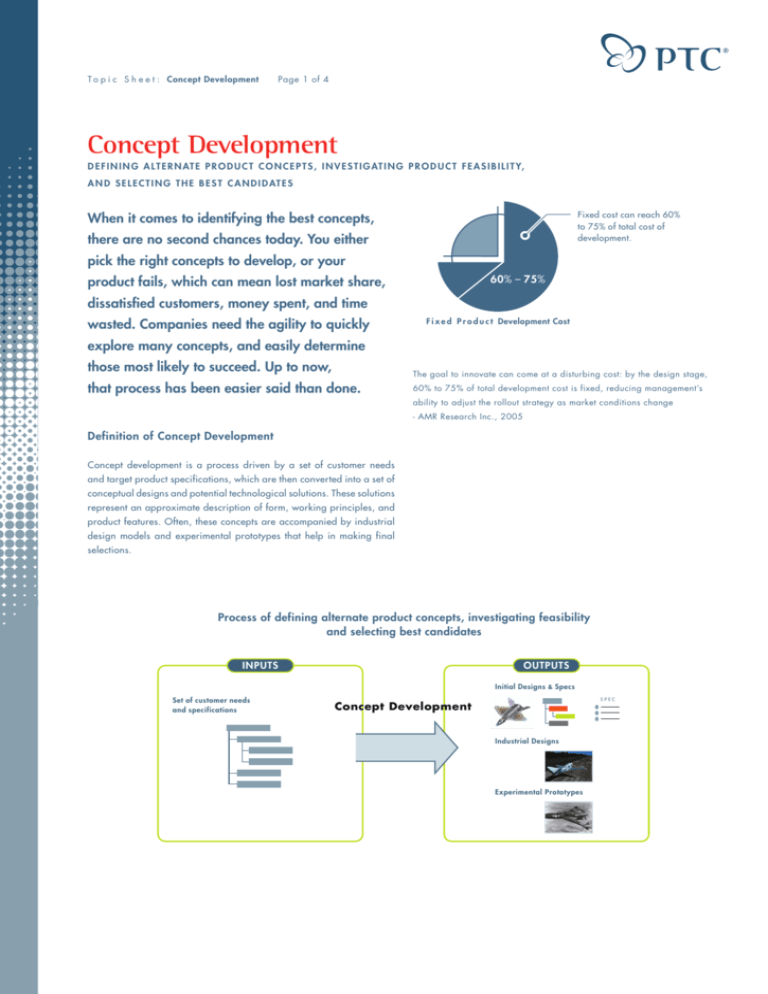

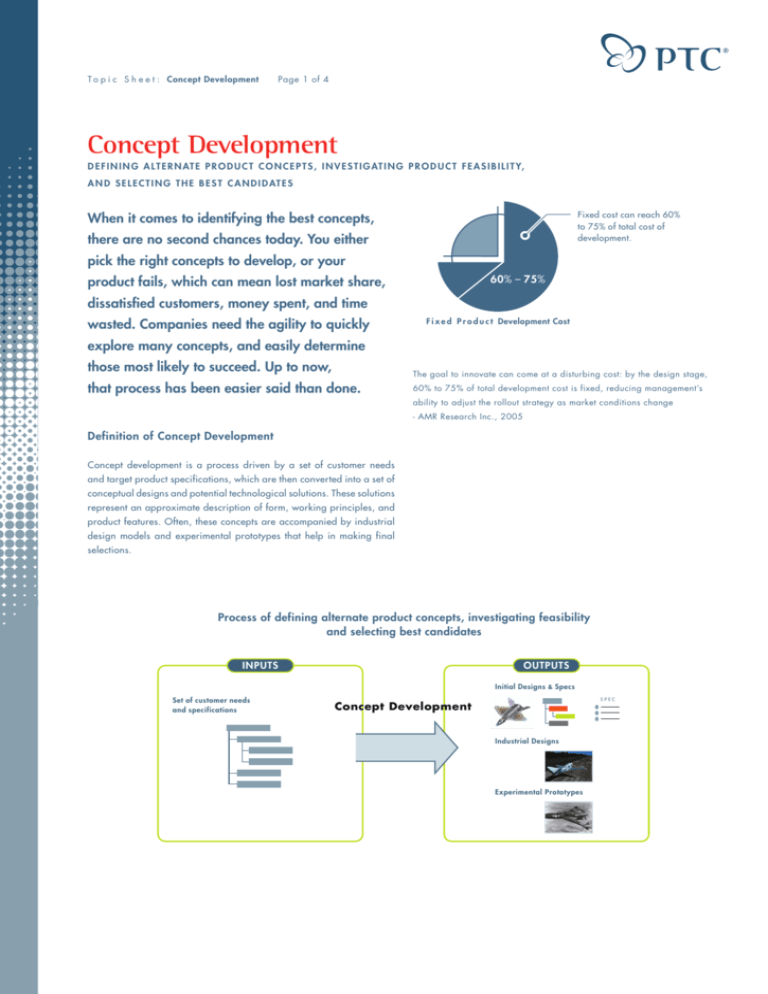

Fixed cost can reach 60%

to 75% of total cost of

development.

When it comes to identifying the best concepts,

there are no second chances today. You either

pick the right concepts to develop, or your

60% – 75%

product fails, which can mean lost market share,

dissatisfied customers, money spent, and time

wasted. Companies need the agility to quickly

F i x e d P r o d u c t Development Cost

explore many concepts, and easily determine

those most likely to succeed. Up to now,

The goal to innovate can come at a disturbing cost: by the design stage,

that process has been easier said than done.

60% to 75% of total development cost is fixed, reducing management’s

ability to adjust the rollout strategy as market conditions change

- AMR Research Inc., 2005

Definition of Concept Development

Concept development is a process driven by a set of customer needs

and target product specifications, which are then converted into a set of

33 %

conceptual designs and potential technological solutions. These solutions

An efficient change process

can cut upwards of 33% off

of the typical product

development cycle time.

represent an approximate description of form, working principles, and

product features. Often, these concepts are accompanied by industrial

design models and experimental prototypes that help in making final

selections.

T O TA L Product Development Cycle Time

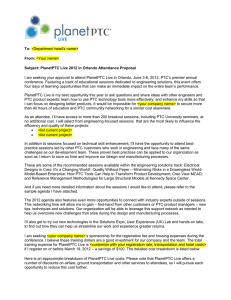

Process of defining alternate product concepts, investigating feasibility

and selecting best candidates

INPUTS

OUTPUTS

Initial Designs & Specs

Set of customer needs

and specifications

SPEC

Concept Development

Industrial Designs

Experimental Prototypes

T o p i c S h e e t : Concept Development

Page 2 of 4

Understanding the Need for Concept Development

Benefits of an Optimized Process for Concept

Development

To remain competitive, every company must encourage innovation and

set the stage for the creation of revolutionary ideas. Yet, organizations

Typical benefits of improving the concept development process can

often lack the discipline to embrace a ‘structured’ approach to concept

include:

development. Unfortunately, this deficiency often decreases the likelihood

of a product’s commercial success.

Ensure Thorough Concept Exploration

• Allow methodical research of all potential sources of solution ideas

No doubt, capturing and formalizing concept development, a task

involving many internal stakeholders, is clearly a challenge. For starters,

• Include all organizational stakeholders in consideration

for concept development to ‘get it right the first time,’ the process must

and exploration of wide-ranging solution ideas

reach out to customers to include their voice in concept review and

selection. Complicating matters is the fact that two key objectives of

• Evaluate previously rejected solution concepts

concept development are in perpetual conflict. On one hand, given

tight timeframes, you want a small set of alternatives, so that you may

• Effectively integrate viable fragmented solutions

thoroughly ensure all requirements are met. On the other hand, you gain

valuable insight and innovation by exploring as broad a set of concepts

Increase Product Design Efficiency

as possible. Thus, the dilemma: how do you simultaneously explore

wide-ranging alternatives while ensuring all your requirements are

• Employ best methods and tools to facilitate a productive concept satisfied – and do it all on time?

generation process

• Adopt a formalized, repeatable, and transparent concept

development processes

• Capture and catalog concept ideas to eliminate redundancy

and increase knowledge reuse

• Improve project execution and visibility of team’s progress

Improve Design Collaboration

• Include the voice of customers in concept evaluation to drive

market acceptance upon product launch

• Reduce the potential for wasted effort, by involving all stakeholders to eliminate non-viable concepts early

T o p i c S h e e t : Concept Development

Page 3 of 4

The Solution – PTC’s Product Development System

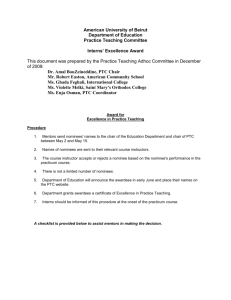

1

Understand Problem

Requirements

Decompose Problem

Requirements Management

The PTC Product Development System (PDS) delivers all the essential tools

for authoring and managing a complete digital product definition – the

key prerequisite for successful concept development. Digital concept

generation tools enable brainstorming, exploration of design ideas, and

development of product concepts within a single environment. With the

2

PDS, product information surrounding concepts is managed in a single,

Search for Ideas

structured, cross-discipline product data repository that offers timely and

role-based access to a globally dispersed product development team.

Customers can be integrated securely and seamlessly into this collabora-

Complete?

tive environment to ensure concept designs meet requirements.

In general, the Concept Development process can be described by three

Organize & Synthesize

major steps: Problem Definition, Concept Generation, and Concept

Evaluation/Selection.

Develop Concepts

1. Problem Definition. In this step, customer needs and requirements

are interpreted as a set of problems to solve. The problems are broken

down and decomposed into simpler sub-problems. Functional breakdown

3

Analyze Concepts

and problem decompositions are captured and documented in nested

Verification

& Validation

document (object) structures, while online design forums and Web-based

Score Alternatives

meetings record preliminary design decisions.

2. Concept Generation. Solutions are researched for each of the

sub-problems, employing internal and external search procedures. Ideas

Combine & Improve

System Design

Approve?

Approved Concept

Concept Documentation

are further explored using various tools for creating a functioning set of

solutions. Designs are developed using an all-inclusive digital sketching

and modeling tool enables the exploration of design ideas and development of product concepts in a single environment, seamlessly bridging

2D and 3D. Photorealistic renderings enable early collaboration with

colleagues, customers and partners. Solution ideas are then organized,

synthesized, and filtered using classification trees and combination tables

to systematically explore the solution space. Solutions to the sub-problems are then integrated into a total solution.

3. Concept Evaluation/Selection. After multiple concept ideas

are generated, they are analyzed using various techniques including

computer-aided-engineering

and

physical

testing

of

prototypes.

Manufacturability, supply chain capabilities, and other aspects of

product feasibility are also taken into account. Virtual 3D models that

are used to capture product form are simulated to assess their intended

function, quality and manufacturing feasibility. Results are collected and

managed in a central data repository so different alternatives can be

screened and scored to quickly narrow the number and to improve the

concepts. The remaining and improved concepts are then ranked against

the selected reference concept and evaluated by the customer, until the

best set of candidates is chosen to be productized.

Concept development process flow

T o p i c S h e e t : Concept Development

Page 4 of 4

Critical Capabilities

The PTC Product Development System offers the following capabilities,

which support an effective concept development process:

• Intuitive, simple application for creation of initial sketches, layouts and facet modeling tools that turn 2D concept representations

into 3D models

• Integrated environment with 3D detailed authoring tools for

streamlined downstream development of digital product concepts

• Photo-realistic visualization, with real-time rendering, to facilitate design reviews and enhance collaboration

• Web-based environment that provides for secure and seamless integration of distributed concept design teams and external

partners

• Integral, physics-based simulation to explore feasibility of

design concepts

• Single, structured, cross-discipline product data repository for

managing and archiving product concepts

• Timely, role-based access to the latest concept design data

to support a globally dispersed team

PTC offers a wide range of capabilities for rapidly exploring

product concepts

PTC – Uniquely Qualified

An automated and optimized concept development process not only

requires superior technology, it also requires companies to streamline

their day-to-day processes. Just as important, companies need to ensure

that everyone across the organization understands and adopts the new

processes and technology.

After 20 years of deploying process and technology improvements

across thousands of customer sites, PTC Global Services understands

all the components required for companies to achieve their product

development goals. We offer solutions that include the right blend of

When it comes to identifying the

best concepts, there are no

second chances today. You either

pick the right concepts to

develop, or your product fails.

process consulting, system implementation, and education services so

customers realize the most value from their PDS investment. We implement industry best practices that fully leverage PTC technology, so companies take advantage of the technology’s potential while avoiding

costly customizations. Plus, each of our solutions incorporates a unique

training approach that accelerates the adoption of new technology

and processes.

© 2006, Parametric Technology Corporation (PTC). All rights reserved. Information

described herein is furnished for informational use only, is subject to change without notice,

and should not be construed as a guarantee, commitment, condition or offer by PTC. PTC,

the PTC Logo, Pro/ENGINEER, and all PTC product names and logos are trademarks or registered trademarks of PTC and/or its subsidiaries in the United States and in other countries.

All other product or company names are property of their respective owners.

2069-Conceptdev-TS-1 2 0 6