fabrication of hastelloy® corrosion-resistant alloys

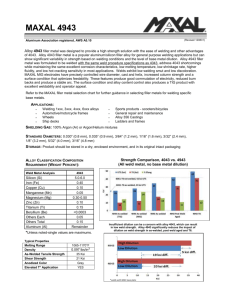

advertisement