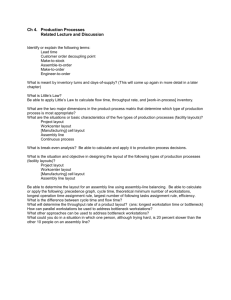

Next Generation Factory Layouts

advertisement