Study Questions Ch 4 Production Processes

advertisement

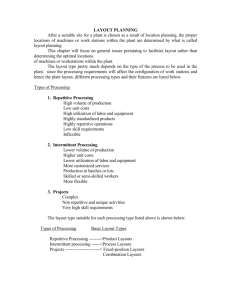

Ch 4. Production Processes Related Lecture and Discussion Identify or explain the following terms: Lead time Customer order decoupling point Make-to-stock Assemble-to-order Make-to-order Engineer-to-order What is meant by inventory turns and days-of-supply? (This will come up again in more detail in a later chapter) What is Little’s Law? Be able to apply Little’s Law to calculate flow time, throughput rate, and [work-in-process] inventory. What are the two major dimensions in the product-process matrix that determine which type of production process is most appropriate? What are the situations or basic characteristics of the five types of production processes (facility layouts)? Project layout Workcenter layout [Manufacturing] cell layout Assembly line Continuous process What is break-even analysis? Be able to calculate and apply it to production process decisions. What is the situation and objective in designing the layout of the following types of production processes (facility layouts)? Project layout Workcenter layout [Manufacturing] cell layout Assembly line layout Be able to determine the layout for an assembly line using assembly-line balancing. Be able to calculate or apply the following: precedence graph, cycle time, theoretical minimum number of workstations, longest operation time assignment rule, largest number of following tasks assignment rule, efficiency. What is the difference between cycle time and flow time? What will determine the throughput rate of a product layout? (ans: longest workstation time or bottleneck) How can parallel workstations be used to address bottleneck workstations? What other approaches can be used to address bottleneck workstations? What could you do in a situation in which one person, although trying hard, is 20 percent slower than the other 10 people on an assembly line?