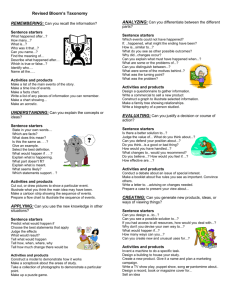

Use of hybrid motor starters in conveyor belts

advertisement

Use of hybrid motor starters in conveyor belts Significant increase in availability Automation technology concerns itself with motion: translational and rotational. Workpieces, semi-finished products, and tools must be moved into particular positions so that they can be processed or used to carry out work steps. Hybrid motor starters from the Contactron product family ensure reliable and low-wear starting and reversing conveyor belt motors at filtration and fluid management specialist Hengst. When the positions of machine parts and workpieces are to be changed, it is often done with three-phase asynchronous motors. Frequency converters usually perform motion in a speedregulated manner. In a modern production unit, servo drives or robots perform many of the precision assembly tasks. For conveyor tasks, or the movement of workpieces from one assembly station to the next, unregulated drives are generally used. These components must also be started, stopped, reversed, and protected from overloading. A good example is the Hengst SE & Co. KG fully automated final assembly (Figure 1). The company, founded in 1958 in Münster, Westphalia, Germany, by Walter Hengst and still owned by his family, develops and manufactures leading filtration solutions for the global market. Around 3,000 employees at ten national and international sites achieved a group turnover of 400 million euros in 2014. The Figure 1 - The factory in Nordwalde is one of the Hengst production sites (image: Hengst). high-quality, multifunctional filtration and fluid management systems are used in passenger and commercial vehicles, ship’s engines, and stationary engines. They ensure that motors, machines, and systems work more cleanly and efficiently, use fewer resources, and improve living conditions around the world. Hengst produces and delivers the entire subsystem including all pressure and die-cast elements (Figure 2). High demands on quality The filtration and fluid management systems have a high level of vertical integration. “At Hengst, manufacturing begins with an aluminum ingot or plastic granulate,” says Figure 2 - The high-quality, multifunctional filtration and fluid management systems are used in passenger and commercial vehicles, among other applications (image: Hengst). Alfons Lehmbrock, project engineer for the company’s proprietary mechanical engineering operation, not without pride. This creates independence from external suppliers and a high degree of flexibility. It also allows Hengst to retain control of the quality of the manufactured products and therefore live up to its own high standards. As Alfons Lehmbrock’s job description implies, self-manufactured production systems including the associated software and electronics design are planned, designed, and constructed by the company itself (Figure 3). In this way, the filtration and fluid management specialist ensures that the production facilities meet the company’s special requirements and maintain high availability, and that maintenance of the systems is optimised to meet the company’s own needs. Hengst has come to offer services in the area of mechanical engineering to other companies as well, even those outside the automotive industry. The extensive know-how of company technicians is thus made available to external partners as well. The forward-looking Industry 4.0 project, which is receiving a great deal of attention, concerns Hengst, too. “But Figure 3 - The production systems and associated electronics design are planned, designed, and installed by Hengst’s own mechanical engineering operation. while most companies are still talking about Industry 4.0, we are already implementing the initial concepts in our own production,” Alfons Lehmbrock says. “Our activities include such aspects as traceability in manufacturing and the combination of one-of-a-kind semi-finished products to form a complete product in which the individual parts fit perfectly.” Significantly more space in the control cabinets Whether they are intended for use at Hengst or to be delivered as high-quality machines, the devices exhibit quality, user-friendliness, and component longevity upon which great importance is placed. This makes it noteworthy that, for the operation of the conveyor belts installed in the high-quality assembly systems, Hengst uses hybrid motor starters from Phoenix Contact’s Contactron product range (Figure 4). The devices start and reverse the three-phase asynchronous motors installed there in a reliable, low-wear manner. Their integrated Figure 4 - For the operation of the conveyor belts installed in the assembly systems, Hengst uses hybrid motor starters from the Contactron product family. overloading function also protects motors from blockages. Like conventional motor protection relays, the hybrid motor starters also report faults that have occurred. If necessary, they shut down the drive safely according to the Machinery Directive. During the process, Performance Level PL e according to DIN EN ISO 13849-1 or Safety Integrity Level SIL 3 according to EN 62061 is achieved. This means that the hybrid motor starters combine four functions within a design width of 22.5 mm A comparable conventional construction would consist of two contactors for clockwise and counter-clockwise motion, two redundant emergency stop contactors, and one motor protection relay. This means that less space is required in the control cabinet (Figure 5). Tenfold increase in service life Phoenix Contact’s hybrid starter technology uses a microcontrollercontrolled combination of wear-free Figure 5 - The 22.5-mm hybrid motor starters combine four functions in a single device, saving space in the control cabinet. semiconductor technology and robust relay technology. While the semiconductors are in charge of the switch-on and switch-off operations, the relay contacts conduct the current without any loss. This results in smooth switching and significantly reduces the load on the relay contacts. Moreover, the approach removes the need for elaborate and costly heat sinks. Furthermore, the service life of hybrid motor starters is ten times that of purely electromechanical switching devices (contactors). The integrated internal load and locking circuits also significantly reduce wiring costs because only six connections must be made for the main circuit. Four LEDs attached to the front of the motor starter indicate device status – operating voltage, clockwise and counterclockwise motion, and error – in different colors. The rated motor current can be continuously adjusted. For error reporting – to the control center, for example – a floating changeover contact is also integrated into the device. Built-in protective circuits ensure that the hybrid motor starters switch reliably even in harsh industrial environments. Because their control inputs use so little current, the devices can be controlled directly through the PLC. Summary Hengst has been counting on the electronic motor starters from Phoenix Contact for many years. “The robust design and the simple wiring and operation were the criteria that led us to choose Contactron,” says Alfons Lehmbrock (Figure 6). The tenfold improvement in service Figure 6 - The robust design and user-friendliness of the hybrid motor starters won over Alfons Lehmbrock, Hengst project engineer. life also proves advantageous, since Hengst works with high switching frequencies. Maintenance cycles become significantly longer, and the installation's availability increases. The hybrid motor starters can be used with motor types of up to about 3 kW for small cargo elevators as well as conveyor belts. Interface system for further simplifying wiring With hybrid motor starters from Phoenix Contact’s Contactron For further information vist: product family, motors can be www.phoenixcontact.co.uk quickly and reliably switched and reversed. Connecting the devices to an interface system develops If you are interested in publishing this article, please contact Becky Smith: marketing@phoenixcontact.co.uk or telephone 0845 881 2222. the efficient wiring concept further. Hybrid motor starters and command and reporting devices are easily and clearly connected with the technology (Figure 7). This makes complex parallel cabling at the control and signal levels almost superfluous in large systems with many consumers. A gateway can be used to integrate the motor starters into the necessary fieldbus system, such as Profibus, CANopen, Profinet, or Ethernet IP. Figure 7 - Connecting the hybrid motor starters to the newly developed interface system continues the efficient wiring concept.