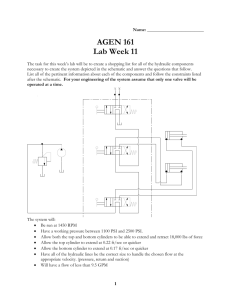

Understanding Truck Mounted Hydraulic Systems

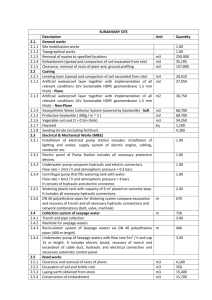

advertisement