Reinforced Concrete Design Design of Slabs

advertisement

16

Reinforced Concrete Design

Design of Slabs

Types of Slabs

Load Paths and Framing Concepts

One-way Slabs

Two-way Slabs

Mongkol JIRAVACHARADET

SURANAREE

UNIVERSITY OF TECHNOLOGY

INSTITUTE OF ENGINEERING

SCHOOL OF CIVIL ENGINEERING

Types of Slab

One-way slab

Flat plate slab

One-way slab

Flat slab

Two-way slab

Grid slab

Load Path / Framing Possibilities

Ln = 3.2 m

Ln = 4.4 m

Ln = 3.6 m

Ln = 8.2 m

Think we’ll need some additional framing members???

Framing Concepts

Let’s use a simple example

for our discussion…

Column spacing 8 m c-c

Think about relating it to your

design project.

Plan

Framing Concepts

We can first assume that

we’ll have major girders

running in one direction

in our one-way system

Framing Concepts

We can first assume that

we’ll have major girders

running in one direction

in our one-way system

If we span between girders

with our slab, then we have

a load path, but if the spans

are too long…

Framing Concepts

We will need to shorten up

the span with additional beams

But we need to support the

load from these new beams,

so we will need additional

supporting members

Framing Concepts

Now let’s go back through with

a slightly different load path.

We again assume that we’ll

have major girders running in

one direction in our one-way

system.

This time, let’s think about

shortening up the slab span by

running beams into our girders.

Our one-way slab will transfer our load to the beams.

Two Load Path Options

Framing Concepts - Considerations

For your structure:

Look for a “natural” load path

Identify which column lines are best suited to having

major framing members (i.e. girders)

Assume walls are not there for structural support, but

consider that the may help you in construction (forming)

Example

Condo Floor Plan

One-way Slab

L

S

m

0

.

1

Main reinforcement

Design of one-way slabs is like design of parallel 1m beams.

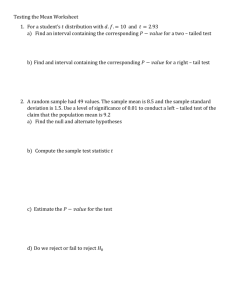

Design of One-way Slab (L > 2S)

1 w

1m

L

S

S

Minimum Thickness (ACI)

Simply

supported

One end

continuous

Both ends

continuous

Cantilever

L/20

L/24

L/28

L/10

*multiplied

by 0.4 + fy/7,000 for steel other than SD40

ACI Design Provision

Shrinkage and temperature reinforcement

For structural slabs only; not intended for soil-supported slabs on grade

Ratio of reinforcement As to gross concrete area Ag : As/Ag

RB24 (fy = 2,400 ksc) . . . . . . . . . . . . . . . . . 0.0025

DB30 (fy = 3,000 ksc) . . . . . . . . . . . . . . . . . 0.0020

DB40 (fy = 4,000 ksc) . . . . . . . . . . . . . . . . . 0.0018

DB (fy > 4,000 ksc) . . . . . . . . . . . . . . . . . . . 0.0018 × 4,000 ≥ 0.0014

fy

Spacing ≤ 5 t ≤ 45 cm

Main Steel (short direction):

As ≥ ∅ 6 mm

Max. Spacing ≤ 3 t ≤ 45 cm

Min. Spacing ≥ f main steel ≥ 4/3 max agg. ≥ 2.5 cm

Effect of column width

b

A

b

A′

B′

B

L

Moment at A’:

w

2

wL2

12

wL

12

b/2

wL

2

b/2

wL

2

wL2 wL b w(b / 2 )

=−

+

−

12

2 2

2

wL2 wLb wb 2

= −

−

+

4

8

12

If A’ and B’ are fiexed against rotation,

2

wL2 wLb wb 2

w(L − b )

M =−

= −

−

+

12

6

12

12

2

Typical reinforcement in a one-way slab

Top bars at

exterior beams

Bottom bars

Top bars at

exterior beams

Temperature bars

Exterior span

Interior span

(a) Straight top and bottom bars

Bent bar

Bottom bars

Bent bars

Temperature bars

Exterior span

(b) Alternate straight and bent bars

Interior span

Example: Design one-way slab as shown below to carry the live

G1

A

S1 S2 S3

A

3 @ 8 m = 24 m

load 500-kg/m2 fc’ = 210 kg/cm2, fy = 2,400 kg/cm2

0.4 + 2400/7000 = 0.74

min h = 400(0.74)/24 = 12.3 cm

USE h = 13 cm

DL = 0.13×2400 = 312kg/m2

4 @ 12 m = 48 m

wu = 1.4(312) + 1.7(500) = 1,286.8 kg/m2

clear span = 4 - 0.3 = 3.7 m

Mu = (1,286.8)(3.7)2/10 = 1,762 kg-m

ρmax = 0.75ρb = 0.75(0.0454) = 0.0341

USE RB9 with 2 cm covering: d = 13-2-0.45 = 10.55 cm

Mu

1762 × 100

Rn =

=

= 17.6 ksc

2

2

0.9 × 100 × 10.55

φ bd

0.85 f c'

ρ=

fy

2 Rn

1 − 1 −

'

0

.

85

f

c

= 0.0077 < ρmax

OK

As = ρbd = 0.0077(100)(10.55) = 8.16 cm2/m

Select RB9@0.07 (As = 9.28 cm2/m)

Temp. steel = 0.0025(100)(13) = 3.25 < 9.28 cm2/m

Select RB9@0.18 (As = 3.53 cm2/m)

OK

L1

4

L1

3

Detailing of one-way slab

Temp. steel

L1

8

L1

RB9@0.18

RB9@0.07

.13 .

RB9@0.10

1.0 .

1.3 .

4.0 .

RB9@0.18

RB9@0.14 #$

.13 .

1.0 .

RB9@0.07

1.3 .

4.0 .

Design of Two-way Slab (L < 2S)

Min. Thickness:

t ≥ 9 cm ≥ Perimeter/180 = 2(L+S)/180

S

L

Reinforcement Steel:

As ≥ φ 6 mm ≥ Temp. steel

Max. Spacing ≤ 3 t ≤ 45 cm

Min. Spacing ≥ φ main steel ≥ 4/3 max agg. ≥ 2.5 cm

Load transfer from two-way Slab

D

C

45o

45o

Short span (BC):

Floor load = w kg/sq.m

S

Tributary area = S2/4 sq.m

45o

45o

A

B

Load on beam = wS/4

wS/3 kg/m

L

Long span (AB): Span ratio m = S/L

2

S

Tributary area = SL/2 - S2/4 =

4

Load on beam

wS 3 − m 2

3 2

2 − m sq.m

m

kg/m

Moment Coefficient Method

%&'

%&'(

%&'

-Ms

%&'(

+Ms

+ML

-ML

%&'

%&'

S/4

-ML

S/4

-Ms

L/4

L/2

S/2

L/4

Middle strip moment: MM = CwS2

Column strip moment: MC = 2MM/3

( C )

$%

"#

1.0

'&(

,

-('-/)

-/0))

,

-'12(3)

4%%

56

67&

,

-('-/)

-/0))

,

-'12(3)

4%%

56

,

-('-/)

-/0))

,

-'12(3)

))*+ m

0.9 0.8 0.7

$%&

0.6

0.5

0.033 0.040 0.048 0.055 0.063 0.083 0.033

0.025 0.030 0.036 0.041 0.047 0.062 0.025

0.041 0.048 0.055 0.062 0.069 0.085 0.041

0.021 0.024 0.027 0.031 0.035 0.042 0.021

0.031 0.036 0.041 0.047 0.052 0.064 0.031

0.049 0.057 0.064 0.071 0.078 0.090 0.049

0.025 0.028 0.032 0.036 0.039 0.045 0.025

0.037 0.043 0.048 0.054 0.059 0.068 0.037

( C )

$%

"#

1.0

4%%

56

,

-('-/)

-/0))

,

-'12(3)

4%%

5756

,

-('-/)

-/0))

,

-'12(3)

))*+ m

0.9 0.8 0.7

$%&

0.6

0.5

0.058 0.066 0.074 0.082 0.090 0.098 0.058

0.029 0.033 0.037 0.041 0.045 0.049 0.029

0.044 0.050 0.056 0.062 0.068 0.074 0.044

0.033 0.038 0.043 0.047 0.053 0.055 0.033

0.050 0.057 0.064 0.072 0.080 0.083 0.050

Bar detailing in slab

L1/7

L1/3

L1/4

L1

L2/3

L2/4

L2

Bar detailing in beam

L1/3

L1/8

L2/3

L1/8

L1

L2

L/5

L/5

L = Example: Design two-way slab as shown below to carry the live

load 300-kg/m2 fc’ = 240 kg/cm2, fy = 2,400 kg/cm2

4.00

0.10

3.80

0.50

0.20

0.20

Cross section

5.00

4.80

Min h = 2(400+500)/180 = 10 cm

DL = 0.10(2,400) = 240 kg/m2

wu = 1.4(240)+1.7(300) = 846 kg/m2

m = 4.00/5.00 = 0.8

Floor plan

As,min = 0.0018(100)(10) = 1.8 cm2/m

Short span

-M()

+M

-M()

Moment coeff. C

0.032

0.048

0.064

Max. M = C w S 2 = 0.064 × 846 × 4.02 = 866 kg-m/1 m width

d = 10 - 2(covering) - 0.5(half of DB10) = 7.5 cm

Rn =

Mu

86, 600

2

=

=

17.11

kg/cm

φ bd 2 0.9 ×100 × 7.52

0.85 f c′

2 Rn

ρ=

1 − 1 −

= 0.0045

fy

0.85 f c′

As = 0.0045(100)(7.5) = 3.36 4.2 > As,min

(63

(718 DB10@0.20 (As=3.90 4.2)

Long span

Moment coeff. C

-M()

+M

-M()

0.025

0.037

0.049

Max. M = C w S 2 = 0.049 × 846 × 4.02 = 663 kg-m/1 m width

d = 10 - 2(covering) - 1.5(half of DB10) = 6.5 cm

Rn =

Mu

66,300

2

=

=

17.44

kg/cm

φ bd 2 0.9 ×100 × 7.52

0.85 f c′

2 Rn

ρ=

1 − 1 −

= 0.0046

fy

0.85 f c′

As = 0.0046(100)(6.5) = 2.97 4.2 > As,min

(63

(718 DB10@0.20 (As=3.90 4.2)

89"8:

;7

%

9

9(2:

Vu

= wuS/4 = (846)(4.0)/4

= 846 ./.

<(88'%

92 φVc = 0.85(0.53) 240 (100)(7.5)

= 5234 ./.

OK

DB10@0.40 #$

DB10@0.20 DB10@0.40 #$

0.10

0.50

0.95

1.30

0.55

0.95

3.80

0.20

6

0.20

DB10@0.40 #$

DB10@0.20 DB10@0.40 #$

0.10

0.50

0.70

1.20

0.20

1.20

1.60

4.80

6&

0.20