textile report 2010

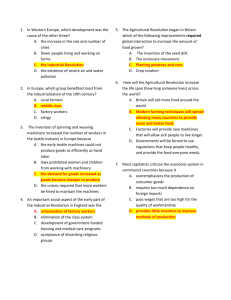

advertisement

Italian Trade Commission - Jakarta Indonesian Textile Industry and Machinery Market Report and Statistics 2009 and 1st Semester of 2010 Country: Indonesia Reference period: January – December 2009 & January – June 2010 1. The general economic situation in the Country for 2009 In 2009, Indonesia’s GDP reached Rp 5,613.4 trillion or US$ 539.84 billion (Rp 2,177.0 trillion based on constant 2000 prices), registering an economic year-on-year growth rate of 4.5%. All economic sectors experienced growth, the highest being the transport and communication sector, registering a year-on-year growth rate of 15.5%. (Avg Exchange rate Rp 9,136.2 per US$). Total exports reached US$ 116.490 billion, representing a downturn of 14.98% over 2008. Non-oil and gas exports dropped from US$ 107.894 billion to US$ 97.472 billion, registering a growth rate of -9.66%. Total imports dropped by 25.03% to US$ 96.86 billion, with non-oil and gas imports decreasing by 21.06% to US$ 77.87 billion, resulting in a trade surplus of US$ 19.63 billion. The inflation rate in 2009 was 2.78%, as compared to 11.06 % in the previous year. Looking ahead, Indonesian economic growth is expected to increase. The increase of the basic electricity tariff effective as of July 2010 is expected to trigger an inflation of 0.22% per month according to the Central Bureau of Statistics, it is likely the the government’s inflation target of 5.3% will be surpassed. The prospect of economic growth is supported by the recovery in exports in line with the improvement in the global economic outlook and an upturn in investment activity. Economic growth in 2010 is projected to reach 5.5%-6.0%. 2. Summary of the economic trend in the textile sector for 2009 The Department of Trade reports that exports of textile and textile articles (including garments) dropped from US$10.3 billion in 2008 to US$ 9.3 billion in 2009, representing a decrease of 9.7%, or 9.1% short of the government’s US$ 10.6 billion target. Imports rose by 11.2% from US$ 4.64 to US$ 5.19 billion, resulting in a surplus of US$ 4.1 billion. The domestic sales of textile and textile products grew by a robust 16.5% in 2009 to Rp 57.7 trillion (US$ 6.3 billion). Italian Trade Commission - Jakarta 3. Imports of textile machines 2009, as against 2008 (in 1000 of US$) Machines Jan-Dec 2008 Jan-Dec 2009 Growth (%) Spinning 45,788.3 53,186.9 Weaving 65,429.9 39,530.9 Knitting 32,116.8 23,223.2 Finishing and others 23,387.5 13,722.1 Accessories 8,767.3 9,934.6 Total 175,489.8 139,597.6 Source: Central Bureau of Statistics, processed Jan-Jun 2010 16.2 (39.6) (27.7) (41.3) 13.3 (20.5) 25,622.7 46,973.1 14,418.2 6,339.3 5,451.0 98,804.3 4. Origin of imported machines January-December 2009 (in 1000 of US$) Country Spinning Weaving Knitting China 9,859.0 15,264.5 3,392.1 Japan 13,711.5 5,293.8 1,929.0 Germany 5,973.8 3,070.3 10,677.4 Taiwan 2,144.0 7,916.7 3,627.1 Korea 1,723.3 709.7 1,912.8 Switzerland 4,714.6 687.8 105.0 Italy 968.9 773.3 613.3 Others 14,091.8 5,814.8 966.6 TOTAL 53,186.9 39,530.9 23,223.2 Source: Central Bureau of Statistics, processed Finishing & Others 2,128.4 659.1 801.3 4,097.9 1,751.5 89.2 316.0 3,878.9 13,722.1 Accessories 3,585.6 1,415.1 1,406.5 1,027.1 240.1 302.9 20.9 1,936.4 9,934.6 Total 34,229.5 23,008.3 21,929.3 18,812.8 6,337.4 5,899.4 2,692.4 26,688.5 139,597.6 Origin of imported machines January- June 2010 (in 1000 of US$) Country Spinning Weaving Knitting Japan 7,099.5 11,330.2 647.0 Korea 1,315.5 385.8 1,647.4 Taiwan 1,508.8 8,731.3 2,027.1 China 3,314.7 11,881.8 3,156.0 Germany 3,654.6 1,035.9 5,394.6 Switzerland 1,532.5 625.9 54.9 Italy 613.1 222.4 854.0 Others 6,584.0 12,759.8 637.2 TOTAL 25,622.7 46,973.1 14,418.2 Source: Central Bureau of Statistics, processed Finishing & Others 753.1 1,321.3 706.7 1,959.9 106.1 263.0 1,229.2 6,339.3 Accessories 1,006.7 205.0 317.6 1,086.8 174.9 89.7 273.8 2,296.5 5,451.0 Total 20,836.5 4,874.9 13,291.5 21,399.3 10,366.2 2,303.1 2,226.2 23,506.6 98,804.3 Italian Trade Commission - Jakarta 5. Positive qualities of Italian textile machinery production and trade Italian textile machinery has a high-quality image in Indonesia and is recognized for their technological innovation, creativity, sophistication, flexibility, durability and reliability, and is acknowledged to be among the best in the market. 6. Shortcomings of Italian textile machinery production and trade Interviews with numerous end-users of Italian textile machinery indicated that the main weakness does not lie in the machines themselves but rather in the weak distribution network and lack of promotion on the part of the local agents and distributors. One of the most important key criteria is the credit/ payment terms. In general, Japanese textile machinery suppliers are known to offer the best payment terms, better than European competitors. Chinese equipment on the other hand offer machines at the lowest prices and are known to have improved their quality. 7. Investments in the textile Industry planned for the near future (5 years) Year 2006 Foreign Investment (PMA) Number & Total Value 61 investments (US$ 424.0 million) Domestic Investment (PMDN) Number & Total Value 7 investments (Rp 81.7 billion) 2007 63 investments (US$ 131.7 million) 2008 67 investments (US$ 210.2 million) 20 investments (Rp 719.6 billion) 2009 66 investments (US$ 251.4 million) 23 investments (Rp 2,645.7 billion) 2010 13 investments (US$ 20.5 million) 4 investments (Rp 5.1 billion) 8 investments (Rp 226.2 billion) Source: Investment Coordinating Board, processed Note: * January – March 2010 The above data is based on investment approvals by the Investment Coordinating Board (BKPM) in the period of January - August 2007, and thus does not necessarily represent the actual investments to take place in the forthcoming five years. 8. Production of various textile products: January - December 2007 (code PRODCOM) Description Code Volume (in kg) Value (in US$) Man-made fibres yarn (17.10.51 to 17.10.55) 8,597,238,125 2,266,849,899 Man-made fibres fabrics (17.20.31 to 17.20.33) 2,997,840,211 4,859,902,675 Cotton yarns (17.10.43) 484,673,659 1,062,353,199 Cotton fabrics (17.20.20) 418,095,538 1,426,092,275 Italian Trade Commission - Jakarta Wool yarns (17.10.42) 774,211 3,957,992 Wool fabrics (17.20.10.22) 2,839,363 13,155,619 Silk yarns (17.10.41) 2,144,498 15,677,549 Silk fabrics (17.20.10.10) 81,432,165 Knitwear (17.72) 6,737,879 (50,129,817 m) 110,468,816 pcs 335,824,639 Socks and Stockings (17.71) 166,909,262 pcs 29,138,214 Source: Central Bureau of Statistics, Larga and Medium Industrial Statistics processed. Year 2007 constitutes the latest official statistical data on production available. 9. Exports of various textile products: January - December 2009 (code NACE/CLIO) Description Man-made fibres yarn HS - Code Volume (in kg) Value (in US$) Cotton yarns (54.01 to 54.06 – 55.09 to 55.11) (54.07 to 54.08 – 55.12 to 55.16) (52.04 to 52.07) Cotton fabrics (52.08 to 52.12) 35,007,014 195,017,398 Wool yarns (51.07 to 51.10) 628,451 3,014,256 Wool fabrics (51.11 – 51.12 – 51.13) 8,708 223,636 Silk yarns (50.04 to 50.06) - - Silk fabrics (50.07) 26,299 271,954 Knitwear (61.09 to 61.10) 81,480,860 1,058,300,323 Socks and stockings (61.15) 8,040,289 88,676,328 Man-made fibres fabrics 356,896,987 744,145,117 150,985,339 828,810,922 107,985,339 259,095,803 Source: Central Bureau of Statistics, processed Exports of various textile products: January – June 2010 (code NACE/CLIO) Description Man-made fibres yarn Man-made fibres fabrics HS - Code (54.01 to 54.06 – 55.09 to 55.11) (54.07 to 54.08 – 55.12 Volume (in kg) Value (in US$) 145,184,237 349,346,904 59,349,696 316,290,551 Italian Trade Commission - Jakarta Cotton yarns to 55.16) (52.04 to 52.07) 47,433,478 128,951,597 Cotton fabrics (52.08 to 52.12) 14,371,391 84,683,108 Wool yarns (51.07 to 51.10) 98,467 492,187 Wool fabrics (51.11 – 51.12 – 51.13) 0 0 Silk yarns (50.04 to 50.06) 19 6 Silk fabrics (50.07) 1,724 17,282 Knitwear (61.09 to 61.10) 29,023,336 384,041,405 Socks and stockings (61.15) 2,784,123 29,712,118 Source: Central Bureau of Statistics, processed 10. Imports of various textile products: January - December 2009 (code NACE/CLIO) Description HS - Code Man-made fibres yarn Man-made fibres fabrics Cotton yarns (54.01 to 54.06 – 55.09 to 55.11) (54.07 to 54.08 – 55.12 to 55.16) (52.04 to 52.07) Cotton fabrics Volume (in Kg) Value (in US$) 69,225,719 235,027,544 75,851,837 486,225,214 23,802,405 59,060,433 (52.08 to 52.12) 88,013,435 633,086,673 Wool yarns (51.07 to 51.10) 159,110 1,317,916 Wool fabrics 1,641,554 34,880,043 Silk yarns (51.11 - 51.12 51.13) (50.04 to 50.06) 348,593 1,262,827 Silks fabrics (50.07) 270,353 3,325,048 Knitwear (61.09 to 61.10) 4,940,355 38,065,426 560,957 2,334,264 Socks and (61.15) stockings Source: Central Bureau of Statistics, processed Italian Trade Commission - Jakarta Imports of various textile products: January - June 2010 (code NACE/CLIO) Description HS - Code Man-made fibres yarn Man-made fibres fabrics Cotton yarns (54.01 to 54.06 – 55.09 to 55.11) (54.07 to 54.08 – 55.12 to 55.16) (52.04 to 52.07) Cotton fabrics Volume (in Kg) Value (in US$) 36,038,391 131,248,607 51,057,039 346,190,205 10,796,092 33,038,697 (52.08 to 52.12) 55,429,076 423,412,853 Wool yarns (51.07 to 51.10) 23,958 326,130 Wool fabrics 1,047,906 21,738,510 Silk yarns (51.11 - 51.12 51.13) (50.04 to 50.06) 216,054 640,052 Silks fabrics (50.07) 169,152 2,337,415 Knitwear (61.09 to 61.10) 1,256,765 14,869,587 228,574 1,283,974 Socks and (61.15) stockings Source: Central Bureau of Statistics, processed 11. Value of production: January – December 2009 Value (in 1000 US$) Textile sector* 3,123,913** Clothing sector 8,344,247 Note: * Excl. Fiber and Spinning/ yarn ** Preliminary Figure based on production index of the Central Bureau of Statistics 12. How did the production structure change in 2009 (number of mills and annual production capacity) The data is no longer available from the Investment Coordinating Board. Note: As of 2008, the BKPM no longer publishes the details of approved investments permits, but merely presents aggregate data for the entire textile sector. Italian Trade Commission - Jakarta 13. Other Events 2009 During 2009, Indonesia’s textile sector was still overwhelmed by imports of cheap Chinese products. One of the reasons causing the difficulty of Indonesian products to compete with Chinese products is that while Indonesia imports some 99.5 % of its cotton requirements, the cotton needs of China’s textile industry are to a large part met from domestic sources. Additionally, China has a comparatively more favorable interest rate than Indonesia and grants tax breaks for export-oriented industries. The second problem faced by the Indonesian textile industry is their aging machinery and the related funding problems. While Indonesia’s rival countries are already using high technology-machinery, most of the machinery in the Indonesian textile industry is out of date, at least 20 years old, including 64.4 percent of 7.8 million spinning machines, 82.1 percent of 248,957 weaving machines and 84.1 percent of 41,312 knitting machines. In 2009, the government once again launched the textile and textile products machinery restructuring program at a total budget allocation of Rp 240 billion for the 2009 budget year. The allocation dropped by Rp 90 billion compared to the previous year, and was the lowest in the past three years. The program consists of two schemes, the first scheme being a price discount granted for the purchase of machinery, while the second scheme mostly serves the interest of medium size businesses, in the form of loans for funding machinery at low interest rates by way of equity participation. Under the former scheme, a fund of Rp 213 billion is allocated, and Rp 27 billion under the latter scheme. The textile machinery restructuring program has been implemented since April 2007. Of the 2007 allocation, Rp 255 billion was used by 92 textile industries with a total absorption of Rp 153.31 billion (60.1%). The textile machinery restructuring allocation in 2008 increased to Rp 330 billion, and was used by 175 textile companies with a total absorption of Rp 181.7 billion (55.1%), which had stimulated an investment of Rp 1.77 trillion in textile machinery. In the second stage, the interest has doubled from 92 to 175 participating companies. While the absorption of the funds has yet to be maximized, the increase in interest is caused by the fact that the banks have started indicating confidence in the textile industries which were previously regarded as highly risky. This increase in the interest of textile industries in the textile machinery restructuring program had encouraged the government in maintaining this program. Allocation for Textile Machinery Restructuring and Absorption, 2007 – 2009 Year Specification Fund Allocation Absorption % 2007 Rp 255.0 billion Rp 153.31 billion 60.1% 2008 Rp 330.0 billion Rp 18 1.7 billion 55.1% 2009 Rp 240.0 billion N.a N.a Source: Ministry of Industry, processed Number of participating companies 92 175 180-200 Italian Trade Commission - Jakarta The machinery revitalization programme is expected to increasing Indonesia’s production by 17% and employment by 25%, and in the process pushing down inefficiency to between 6 – 18%. The revitalization of the textile industry and textile products (TPT) nationwide in the next 10 years (until 2020) is estimated to require an additional investment of US$ 6.53 billion, or around Rp 60 trillion to strengthen the industrial structure and competitiveness to face the free market: New Capacity (Million Ton) Value in (Rp Trillion) 6 24.19 4.9 5 19.62 4 2.9 3 10.74 2.5 2.1 2 5.54 1 0 Viscoce Fiber Yarn Cloth Garment Viscoce Fiber Yarn Cloth Garment 2010 The performance of the textile sector has somewhat weakened with the soaring prices of polyester fibers in the domestic market, following the application of anti-dumping duties by the anti-dumping committee in May 2010 on china (11.94%), India (5.82 to 16.67%) and Taiwan (28.47%) as a result of which the local prices of synthetic polyestyer fibers jumped by 15.5%, which had a systematic impact on downstream textile industries nationwide, namely the yarn, fabric and garment industries to be hampered by rising production costs. The textile industry is still facing difficulties to obtain bank loans. Owing to higher lending rates, which in a number of banks reach up to almost 16%, most of the Indonesian textile manufacturers had to bear currency risk, as they were compelled to borrow from international banks. Banks are generally still of the opinion that the textile sector is a dying industry. Bank Indonesia, in one of its recent survey revealed that banks still refrain from providing loans, given the inability of local manufacturers to compete with imported goods, especially Chinese goods. The government has increased the industrial electricity rates by 18%, which will raise the prices of Indonesian textiles by sbout 7.2%, reendering domestic products uncompetitive. The ASEAN-China Free trade agreement (AC-FTA) has become the most challenging issue in recent times in Indonesia, especially for the textile industry. The ASEAN-China which became effective from January 1, 2010 entails zero tariffs on 6,682 tariff lines in 17 sectors, including 12 in manufacturing, and five in agriculture, mining and maritime sectors. Indonesia is not ready to participate in the FTA treaty since Indonesian companies are not well prepared and competitive to face the influx of Chinese goods. This challenging issue is aggravated by a lack of information which inhibits the textile industry’s awareness of the necessity to become well prepared for the liberalization of Italian Trade Commission - Jakarta global trade. The FTA was signed between the ten countries of ASEAN and China on August 15 in Bangkok and is also binding on Indonesia. Three industry sectors are facing a serious threat; i.e. textiles, steel and the machine tools industry. The government’s role to provide protection and support for the industry to face this situation is urgently needed to keep the market balance and help the most impacted sectors to survive in the fierce competition. Even though Indonesia had time to improve its infrastructure facilities from the time the negotiations for the FTA agreement began in 2005, but the drive to upgrade infrastructure never took off, due to the lack of will and foresight of the government. 14. Expected changes The government’s financial assistance granted through the textile machinery restructuring program is expected to significantly boost the growth of the textile and textile products industry in Indonesia. Exports are expected to increase by approximately 10% per year, surpassing US$ 10 billion. This program is also expected to absorb an additional 52,000 workers. In the near term, as many as 80 textile and garment producers in West Java are expected to spend about Rp 2 trillion to revitalize their machinery and plants this year, twice the investment expended in 2007, which amounted to Rp 910 billion. The investment will raise the installed capacity of the textile industry, from US$13 billion to US$16 – 17 billion. Expansions by West Java producers will impact the whole industry, as they represent 67% of the country’s textile and textile products production. The investments are necessary to achieve the government’s target of gaining 3% share of the global textile market. The textile demand in the domestic market is expected to continue to grow with Indonesia’s improving economy and increasing population. In the coming years, Indonesia’s consumption of polyester fiber is expected to continue to increase. With the limited production of cotton fiber, the country will concentrate more on developing its synthetic fiber industry, especially polyester fiber industry. The demand for polyester fiber, especially PSF, is predicted to continue to rise as polyester remains dominant as the basic materials for yarns in the country. 15. New laws and regulations for the textile industry enacted in the period taken into consideration In 2009 and 2010, four new regulations for the textile industry were enacted as follows: • Decree of the Ministry of Industry of the Republic of Indonesia No. 141/MIND/PER/10/2009 dated 19 October 2009 regarding the restructuring program of textile and leather machinery • Decree of the Ministry of Industry of the Republic of Indonesia No. 131/MIND/PER/10/2009 dated 14 October 2009 regarding the Road Map for the development of garment cluster Industries • Decree of the Ministry of Industry of the Republic of Indonesia No 30/MIND/PER/3/2010 dated March 2010 on the second Amendment of the Decree No Italian Trade Commission - Jakarta 15/M-IND/PER/3/2008 on Restructuring Program of Textile and Textile Products Machinery. • Decree of the Ministry of Trade of the Republic of Indonesia No 02/MDAG/PER/1/2010 on the Amendment of the Decree No. 23/M-DAG/PER/6/2009 on the Import Regulations of Textile and and Textile Products. 16. Tenders in the period considered (please indicate the details of the tender and briefly illustrate its object) In the general announcement of tenders conducted in the period of 2009 and first half of 2010, none covered in the textile industry. 17. New joint ventures between textile producers or textile machinery manufacturer, if any (specify only partners and object) Based on data from the Data Center of the Ministry of Industry, in 2009 no new textile machinery component manufacturer was established. Up to now, Indonesia only has one integrated producer of textile machinery, i.e. PT Texmaco Perkasa Engineering of the Texmaco Group. The company produces air-jet and water-jet weaving machines, rapier shuttle-less looms, seizing machines, printing machines, stenter machines, dobby machines, steamers and spare parts, mainly for the group’s own operations and partly for exports. The machines are produced with the technology of MS Machinery from Italy, ICBT from France and Draper Inc. of the US. Texmaco Perkasa Engineering, PT Head Office: Jl. H.R. Rasuna Said Kav. X.6 Phone: 002-12520656, Fax: 002-15225738 Factory Address 1: Kiara Payung Klari, Klari 41300 – West Java Phone: 0267-431645 Fax: 0267-432312 Factory Address 2: Jl. Raya Kaliwungu Km 19, Kaliwungu – Central Java Phone: 0294-81253 Fax: 0294-81861 Industry Code: 29263 Headcount: 2247 Contact Person: Anang Sukantono (HRD Manager) Email: mustofa@perkasa.co.id Perkasa Heavyndo Engineering, PT (Subsidiary) Product: Weaving Machines Office Address: Jl. H.R. Rasuna Said – Jakarta Factory Address: Jl. Raya Kaliwungu Km.19 – Kaliwungu 51372 – Central Java Phone: 024-660055 Fax: 024-6600271 Headcount: 337 Italian Trade Commission - Jakarta Contact Person: Nurcholis Habib (HRD Manager) The latest list of textile machine components manufacturers are provided in the appendix of the report. 18. New textile machines agencies Records at the Department of Trade indicate that no new textile machine agencies were established in 2009. Information was obtained that in many cases existing textile machinery agencies have broadened their variety to include more brands. 19. New trading companies The data is no longer available from the Investment Coordinating Board. Note: As of 2008, the BKPM no longer publishes the details of approved investments permits, but merely presents aggregate data for the entire textile sector. The Department of Trade publishes directories of trading companies in operation, but do not provide lists of new textile trading companies. 20. New Engineering Companies Data from the Department of Industry and Department of Trade and Investment Coordinating Board indicate that no new engineering companies in the field of textiles were established in 2009. Italian Trade Commission - Jakarta Appendix Hereunder is the latest list of textile component manufacturers published by the Department of Industry in 2010. Source: Data and Information Center, Departement of Industry 1. Altindo, PT Product: Weaving Comb Factory Address: Jl. Margacinta No. 72 – Margacinta 40287 – West Java Telp: 021-7563008, Fax: 021-7563272 Head Count: 32 Contact Person: Sulaeman (Ass. Accounting) 2. Around Star, PT Product: Hand Knitting Office Address: Factory Address: Jl. Cilampeni No. 12A RT 03/02, Ketapang – West Java Telp: 021-7563008, Fax: 021-7563272 Head Count : 62 Contact Person : Weng Chih Feng (Director) 3. Bengkel Mesin Garuda Product: Spare-parts Office Address: Factory Address: Jl. Komodor Udara Supardio – Cicendo 40174 – West Java Telp: 022-6031303 Fax: 022-6015304 Head Count: 42 Contact Person: Yetty SE (Admin. Staff) 4. Bengkel Tisna Product: Pen Press Office Address: Factory Address: Jl. A. Yani No.580, Kiorocondong 40282 – West Java Telp: 022-708018 Fax: 022-772711 Head Count: 24 Contact Person: Siti Halimah (Admin. Staff) 5. Bintang Permata, CV Product: Spare-parts Office Address: Factory Address: Jl. Burangrang No. 22 Lengkkong 40262 – West Java Telp: 022-7306591 Fax: 022-7310419 Head Count: 67 Contact Person: Allin Rumiyati (Accounting) Italian Trade Commission - Jakarta 6. Falmac Jaya, PT Product: Textile Machines Office Address: Factory Address: Jl. Raya Batujajar Km 3.2, Batu Jajar 40561 – West Java Telp: 022-6866104 Head Count: 32 Contact Person: Teddy Hanafi (Director) 7. Hangga Bengkel Product: Spare-parts Factory Address: Jl. Cijerah No. 33, Bandung Kulon 40212 – West Java Telp/Fax: 022-635148 Head Count: 32 Contact Person: Handi Mulyana (Director) 8. Ekaprima, PT Product: Weaving Comb Factory Address: Jl. Panghegar Permai No. 62 – Cibiru 40613 – West Java Telp/Fax: 022-7800617 Head Count: 54 Contact Person: Yahya Hamdani (Admin. Staff) 9. Sinar Honda Jaya, PT Product: Garment Manufacturing Equipment Factory Address: Kawasan Industri Indotaisai, Cikampek 41373 – West Java Telp: 022-35156466 Fax: 022-351563 Head Count: 54 Contact Person: 10. Sintotex Lestari, PT Product: Textile Machinery Factory Address: Jl. Cibaligo Mancong No. 268, Cimahi Selatan – West Java Telp: 022-638400 Head Count: 54 Contact Person: Henny (Admin. Staff) Email: 11. Fermatik Product: Weaving Equipment Factory Address: Jl. Waru – Tambak Sawah 6A – East Java Telp/Fax: Head Count: 39 Contact Person: - Italian Trade Commission - Jakarta 12. Asia Protendo Graha Product: Cutting & Sealing Machines Factory Address: Jl. Raya Solo – Boyolali Km 14, Banyudono 57273 – Central Java Telp: 0271-780150 Fax: 780149 Head Count: 94 Contact Person: Pono Budi Sutrisno, Dipl. (Director) 13. Logam Indonesia Product: Weaving Machines Factory Address: Batur, Tegalrejo, Ceper 57465 – Central Java Telp: 0272-551381 Head Count: 22 Contact Person: Ny. Haryono (Owner) 14. Sahabat Kerja Product: Textile Machinery Spare-parts Factory Address: Jl. Ds. Tegalrejo, Ceper 57465 – Central Java Telp: 0272-51233 Head Count: 25 Contact Person: Sukiran (Owner) 15. Setia Abadi Logam, PD Product: Textile Machinery Spare-parts Factory Address: Jl. Ds. Kradenan III No. 1A, Pekalongan Selatan 51132 Central Java Telp: 0285-25058 Head Count: 48 Contact Person: Sapto (Staff) 16. Singer Product: Textile Machines Factory Address: Sentono Ngawonggo, Ceper 57465 – Central Java Telp: 0272-51249 Head Count: 34 Contact Person: H. Hardi (Entrepreneur) 17. Sugiarto Product: Packing Bowl Factory Address: Pagongan RT 3 / 4 Dukuh Turi 52192 – Central Java Telp: 0272-55960 Head Count: 20 Contact Person: Sugiarto (Manager)