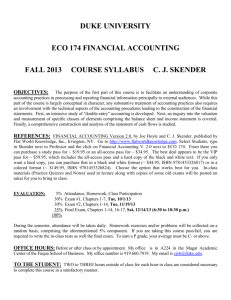

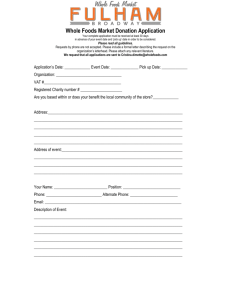

Whole Foods Market Midwest Regional Office Case Study

advertisement

project focus Facing an already aggressive schedule, Skender Construction brought expertise, collaboration and commitment to deliver Whole Foods Market ® an inviting and sustainable Midwest Regional Office – under budget and three weeks early. While Whole Foods Market has proven experience in developing retail facilities and suburban greenfield sites, this 36,000 square foot tenant fit-out needed to be executed within three months and within an occupied urban high rise – without compromising the mission-driven company’s well-defined aesthetic and brand. Whole Foods Market entrusted Gensler as architect and Skender Construction to bring their expertise in the office market to the job. Michael Sweatt, Whole Foods Market’s executive construction coordinator noted, “With our new Regional Office, we made significant improvements in every category, from spatial and functional relationships, and ample daylight, to special areas such as our community kitchen that supports team members. We have an inviting, team member-friendly office on par with our stores – a workplace that says a lot about our products. Everyone worked together to deliver the project ahead of schedule, with a quality look and feel.” Skender project manager Tim Rogers concurred that collaboration set the framework for success. “A project as quickly and intensely executed as this depends upon great teamwork. Whole Foods Market is a knowledgeable client. Gensler went above and beyond to make decisions and work with us to expedite accordingly. We put our expertise and experience on the line, and committed to meeting the schedule.” Freshness and quality are essential to the food industry. Mix in customer satisfaction, team member support and caring for the environment and community, and the result is a recipe for explosive growth. Austin-based Whole Foods Market is the world’s leader in natural and organic foods, and one of Fortune’s “100 Best Companies to Work for in America.” When Whole Foods Market’s Midwest Regional Office moved to a new leased space at 640 North LaSalle Street in downtown Chicago, these same ingredients – the company’s core values – became the touchstones for the design and construction team. The regional office had grown considerably over the past twenty years, surpassing capacity of existing space. The LaSalle location met criteria of proximity to an existing store, a central Chicago area address, and access to mass transit. It also offered opportunities to align the workplace with retail facilities, achieve a higher level of sustainability and flexibility for future expansion, house team members on the same floor, and create areas for large group meetings. 10 | ELEVATION The design for Whole Foods Market’s Midwest Regional Office connects approximately 100 office-based employees – buyers, financial, team member services, IT, marketing, construction and real estate, leadership and support – with stores and brand. With experience on Whole Foods Market’s Chicago Lincoln Park store, Gensler became embedded in the culture, and worked closely with Whole Foods Market’s in-house design, branding, and construction specialists to share resources and bring the company’s story into a highly collaborative workplace through product accessibility, story-telling points, and truth in sustainability and materiality. Gensler senior associate Kate Clemens Davis said, “The LaSalle space lacked the loft style we originally intended. Instead, we took advantage of location and windows to connect employees to the fabric of the city, and create an aesthetic in keeping with the stores. Through careful sustainable selections, we expressed the unique duality of the Midwest – rural and urban – to raise Whole Foods Market’s branding of farm-to-table up a notch.” In discussions with Gensler, Whole Foods Market made the decision to select the general contractor early on and involve them in the design process. Skender was invited to respond to general conditions and interview, and was selected based on reputation, experience, and knowledge of construction type. Michael Sweatt recalled, “Skender Whole Foods Market Headquarters ©2012 Eric Laignel ELEVATION | 11 “With our new Regional Office, we made significant improvements in every category, from spatial and functional relationships, and ample daylight, to special areas such as our community kitchen that supports team members.”— 12 | ELEVATION Michael Sweatt, Whole Foods Market project focus stood out with the positive confidence of hands-on experience and knowing what they could do for us.” With open communication as the foundation on which to build, Skender worked closely with Whole Foods Market and Gensler to uphold integrity of design, including special areas such as kitchens, communal space and sustainable components. Careful estimating and value engineering helped bring the project in under budget. Recycling and repurposing surplus furniture put sustainable values to work and kept costs down. Best green practices included reutilizing equipment where possible, such as the air conditioning unit, and coordinating with millworkers to secure locally sourced materials. Whole Foods Market brought a number of suppliers and subcontractors familiar with its retail facilities to the job, integrated through strong team relationships and cooperation. Greg Huette, associate at Gensler, cited examples of attention to detail, such as the design-build wood ceiling in the lobby, and exposed ceiling over the community table. “When we needed ideas, Skender offered suggestions that did not add extra expense. They understood what is best for the project, and were attentive to details that were important to the finished product.” Without typical ceilings in which to hide infrastructure, installations relied on neat organization, placement at right angles, and deliberate spacing of conduit runs to attain the desired aesthetic as well as functional results. Another element requiring extra care was polished concrete flooring. Tom Hall, senior superintendent for Skender, pointed out, “We did what it takes on the front end to protect surfaces during construction. We used sheets of hardboard and foam to safeguard the finish and not have to touch up the floor later on.” When construction scheduling was compressed by a month to meet the client’s adjusted targets, the team was quick to make every day count. For example, lead time associated with getting materials on the job site for installation could have been a major obstacle. Procurement is generally a 1-2 week, back-and-forth process among architect, contractor, and suppliers involving a sequence of shop drawings, submittals, internal reviews, and approvals before release and shipment. Ramiro Trevino, Skender’s project engineer, recounted the effective response to compress procurement. “We did not have the luxury of time. We all came together at the table to review, approve, and expedite submittals on the same day for each trade, from lighting to mechanical equipment.” Andy MacGregor, Skender project executive, underscores that quality was never sacrificed for speed. “We invested in understanding project scope at the front end to make things were successful and smooth on the back end.” With Skender overseeing daily review of progress and Gensler on the job site weekly, items were handled in the field as an integrated team. Construction activities were carefully coordinated with the building landlord and staged during evenings to avoid disruption to other tenants. And because construction finished three weeks ahead of time, the punch list was turned in 100% complete – another factor contributing to quality control. Whole Foods Market’s construction services group built enthusiasm for the project among employees by sharing Skender’s construction status reports as an internal communication tool. These weekly updates aligned progress photography and descriptions with way points marked on floor plans. For Michael Sweatt, weekly face-toface meetings and the photographic updates were “very helpful in keeping us advised of the progress, evaluating the next tasks ahead, and who needed to be involved.” Since opening, Whole Foods Market’s story is being told within the new office, and already word is getting out. The Regional Office is hosting other regions as they tour stores in the Midwest, and setting the new workplace example, company-wide. Expansion within the remaining 9,000 square feet of the floor plate is next to be served. For now, the main course has been fulfilled. ± clientWhole foods market//architect Gensler//EngineerMcGuire Engineers, Inc.// Lead time was also critical to Whole Foods Market’s IT group and getting their network up and operational. Skender worked closely with McGuire Engineers, Inc. to seamlessly interface HVAC, power, and security requirements, and complete the Intermediate Data Facility space well ahead of the substantial completion date. ELEVATION | 13