Temperature Lab

advertisement

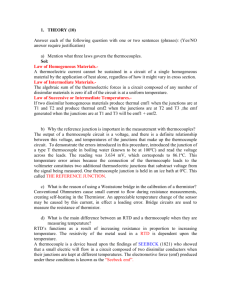

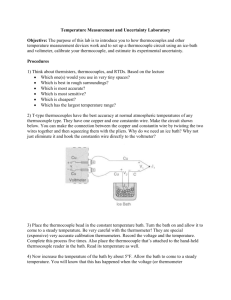

650:349 – Mechanical Engineering Measurements Laboratory #6 Fall 2006 Temperature Measurements I. PURPOSE The purpose of this laboratory exercise is to demonstrate the use of four different temperature sensors: Mercury in Glass Thermometer, Resistance Temperature Detector (RTD), Thermocouple, and Thermistor. II. BRIEF DESCRIPTION OF TEST APPARATUS AND SENSOR OPERATION. a. Mercury in Glass Thermometers. The mercury in glass thermometer is a familiar device which operates on the principle of thermal expansion. The coefficient of thermal expansion of the mercury is much greater than that of the glass encasement. When the thermometer is subjected to changes in temperature, the mercury expands or contracts depending upon the temperature increases or decreases. The fluid expansion is quite small, so a very narrow tube is needed in order to visually observe the change in volume. The glass encasement is calibrated so that a change in mercury volume (measured as a change in length of the mercury column) corresponds to a known change in temperature. Figure 1. Typical Mercury Thermometer b. Resistance Temperature Sensor (RTD). The electrical resistance of materials is temperature dependent. For most materials the resistance increases with temperature. This property can be utilized in measuring the temperature. A common material for RTD sensors is platinum because of its high temperature coefficient of electrical resistance. A platinum wire of suitable length Figure 1. Typical RTD Sensor and diameter is wound around a ceramic cylinder and encased in a steel protective tube. The resistance change of the sensor can be measured using an electrical resistance bridge circuit, and the results displayed using a calibrated indicator registering the resistance of the sensor in Ohms or using a Wheatstone bridge to detect small changes in voltage associated with small changes in resistance. c. Thermocouple. When two dissimilar metals are placed in contact, to form a junction a potential difference is created across the junction. The magnitude of the open circuit potential difference across the junction is temperature dependent and is called the Seebeck effect. If the junction is between wires of dissimilar metals which are part of an electrical circuit through which current flows, then the potential difference measured across the junction is also a function 1 of the current flow through the junction (Peltier effect), as well as the temperature gradients that may exist along the wire (Thompson effect). By measuring the open circuit voltage across the junction (no current flow) and also by minimizing the effect of temperature gradients, the measured voltage across a junction of dissimilar wires can be used to measure the temperature of the junction. The voltage measurement must be carried out at no current flow conditions. Figure 3. Example Thermocouple Tips Figure 4. Typical Thermistors d. Thermistor. A thermistor operates in the same fashion as an RTD, but the sensing element is a semiconductor while the RTD sensor is a metallic element. Thermistor resistance, however, responds negatively and non-linearly to temperature. In addition, the thermistor possesses a higher sensitivity with respect to temperature. Measurement of the resistance can be accomplished using resistance bridge circuitry (variants of the Wheatstone bridge). III. EQUIPMENT a. A Uniform temperature circulating water bath. The temperature of the circulating water bath can be adjusted to any value up to the boiling point of water, but should be set not to exceed 80 °C. Some time should be spent familiarizing with the method of operation and the controls. The cover of the water bath is provided with a set of taps for mounting the sensors at different positions within the bath. Important. Do not turn off the circulating pump of the water bath if the temperature is above 50 °C. Instead, lower the temperature setting and allow the water to circulate until the temperature drops below 50°C. Then the unit can be turned off. b. An Ice/Water bath container. Should be filled with crushed ice to provide a uniform medium at 0°C. c. Panel meters. -A direct measuring temperature indicator for type K thermocouples. -A mV indicator (or multimeter) with suitable connections for a type K thermocouple with cold junction compensation at 0°C. -A resistance measurement panel meter (or multimeter) using resistance bridge circuitry. d. A Digital Multimeter. For measuring sensor resistances as needed. Some time should be spent familiarizing with the different function controls. 2 e. Temperature Sensors. Mercury in glass thermometer, RTD sensor, thermistor sensor, three type K thermocouples, and a fourth K type thermocouple for cold junction compensation. h. PC controlled Data Acquisition System. A PC has been fitted with a data acquisition card and an external eight channel terminal board to acquire, display, and store eight different analogue signals. For the present experiment, the system will be used with only two of the channels active. These channels are connected to a thin K-Type thermocouple, and a thick K-Type thermocouple. The software use is LabVIEW, a package used for monitoring and controlling experiments in an industrial environment. IV. PROCEDURE a. Using the thermometer, measure the room temperature. b. Measure the temperature of the ice bath using a type K thermocouple, using the direct input or temperature panel meter. c. Insert the RTD probe into the ice bath and plug the detector output into the RESISTANCE THERMOMETER INPUT of the panel meter (or the multimeter). Set the OHM/mV switch to OHMS and let the sensor reaches thermal equilibrium. After reaching thermal equilibrium, record the resistance at 0°C. Then re-insert the RTD detector in one of the water bath top taps. d. Insert the thermistor probe into the ice bath and measure its 0°C resistance after it reaches thermal equilibrium. Then re-insert the thermistor probe into one of the water bath top taps. e. Connect one of the thermocouples to the direct reading meter panel and the other thermocouple to the HOT JUNCTION panel meter terminals. The cold junction thermocouple should be placed into the ice bath and its terminals connected to the COLD JUNCTION panel terminals as in Figure 5. Record the voltage from the hot/cold thermocouple circuit using the multimeter or panel meter at room temperature. The third thermocouple should be wired to the inlet board of the PC data acquisition system. f. Set the temperature of the water bath to 25 °C using the combination pump/heater. Launch the LABVIEW program for monitoring the Yellow Wire bath temperature. After steady state is reached (you’ll know by checking the thermocouple Red Wire attached to the PC), record the following: the B R resistance of the RTD, the resistance of the Hot thermistor, the voltage (mV) of the cold Red Wire compensated thermocouple connection, and B the temperature of the bath. Check for temperature uniformity within the water bath R Yellow Wire (i.e. move the thermocouples to different insertion points in the bath to see if the Cold temperature is the same). Figure 5. Cold junction compensated thermocouple connection 3 g. h. i. Yellow Wire Increase the bath temperature to 55 °C in 10°C steps and record the same sensor readings (temperature, voltage, or resistance) as in (f) at each step. Periodically check the temperature uniformity within the bath. With the bath at a steady temperature of 55 °C disconnect the hot/cold thermocouple circuit and connect three Ktype thermocouples as shown in Figures 6 (a thermopile circuit). Record the emf reading (voltage) from the thermopile circuit using the multimeter or panel meter. Also using a glass thermometer, record the temperature in the vicinity of the panel meter thermocouple terminal inputs. Red Wire Hot Room Temp Yellow Wire R B Red Wire Hot Red Wire B R Yellow Wire Cold Figure 6. Series hot junction thermocouple connection (thermopile). Measure transient responses of the two thermocouples connected to the PC data acquisition system and LABVIEW. 1) Measure the diameter of the thin and thick thermocouple shields. 2) Start the LABVIEW data acquisition system to record the temperatures of both thermocouples. Use a fast data rate. QUICKLY insert the thin and thick tube thermocouples into the 55 °C water bath. Let them reach thermal equilibrium (about 2-3 second). Then remove them (quickly) from the bath and let them cool to ambient temperature. Try to hold the thermocouples as still as possible after removing them from the heat bath. V. CALCULATIONS AND RESULTS In the absence of a temperature standard for measuring the bath temperature, we will assume that the temperature indicator of the bath registers the true bath temperature. A. RTD The resistance of an RTD circuit should vary linearly with temperature. Find the constant α for your data assuming that T0 is 0°C and R0 is the value of the resistance when T = T0. Plot the values for the RTD resistance versus temperature and use a linear fit. Compare value of α with that of Platinum given in your text. R = R0 [1 + α (T − T0 )] B. Thermistor 4 The resistance of a thermistor should vary non-linearly with temperature. Find the constant β for your data assuming that T0 is 0°C and R0 is the value of the resistance when T = T0. Plot the values for Thermistor resistance versus (1/T-1/T0) and use an exponential fit. ⎡ ⎛ 1 1 ⎞⎤ R = R0 exp ⎢ β ⎜⎜ − ⎟⎟⎥ ⎣ ⎝ T T0 ⎠⎦ C. Thermocouple Find attached a table of emf (voltage) versus temperature for a K-type thermocouple. Compare your voltages with those in the table for your measurements with a single TC, a cold compensated circuit, and the thermopile circuit. For transient measurements, an unsteady heat transfer analysis shows that: ⎛ ⎛ 3h ⎞ ⎞ T − T∞ t ⎟⎟t ⎟ = exp⎛⎜ − ⎞⎟ = exp⎜⎜ − ⎜⎜ ⎟ Ti − T∞ ⎝ τ⎠ ⎝ ⎝ ρc v R ⎠ ⎠ where: h = the heat transfer coefficient cv = the heat capacity of the sensor material ~ 520 J/kg-K R = radius of thermocouple shield Ti = the initial sensor temperature τ = the time constant t = time (sec) ρ = the density of the sensor material ~ 8.7 gm/cm3 = 8700 kg/m3 T = the sensor temperature T∞ = is the ambient temperature into which the TC is inserted (water or air) Rthick = 1.59mm Rthin = 0.80mm See the helpful guide on reducing the raw data. Plot the natural log of your normalized temperature data (left hand side of equation above) with respect to time and find τ through a linear curve fit. Then use τ to find the heat transfer coefficient (h) for water and for air using the constants given and the radius of the thermocouple shield (measured previously). VI. REPORTS. Items you might include in your lab report • • • • • • • • Discuss and calculation of hot/cold junction circuit Discussion and calculation of thermopile circuit Comparison of recorded thermocouple voltages with given emf values Constants β and α from the thermistor and RTD measurements Estimation of thermocouple heat transfer coefficients Thermocouple time constants (τ) Variation of temperature with time for transient thermocouples tests Comments on time response of all types of gages tested 5 This report should have the format as described in the class guidelines described online: General Guidelines in Section 2 of the general guidelines. IMPORTANT: The Laboratory reports are LIMITED to FOUR PAGES! ANY MATERIAL presented on additional pages will not be considered part of the report. Laboratory reports may contain a maximum of 5 FIGURES and 2 TABLES! What you include in these figures/tables is your choice; however, use the lab handout and class lecture notes as your guide to determine what the most important measurements you’ve made are. Then create figures which best describe and present the data you have collected as well as support your conclusions. 6 7