Service and Maintenance Manual for E1000-series

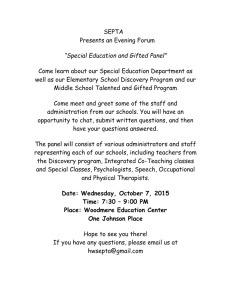

advertisement