Welding Instruction Manual - Pipe Fitters' Training Center Local

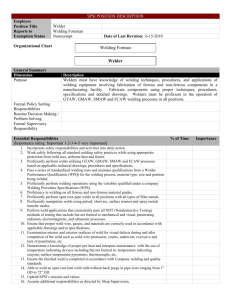

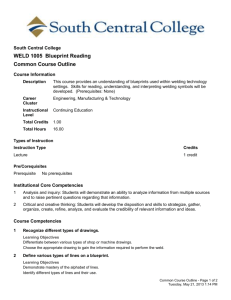

advertisement