customerspotlight

Multidiscipline CAM Helps Carbide Products

Respond Quickly to Customer Needs

By Jerry Fireman

Established in 1943, Carbide Products, Inc., of Georgetown,

KY, is a leading multidiscipline machine and tool job shop

that manufactures made-to-order high-precision parts,

tools, dies and assemblies for customers around the world.

The complex tools and parts manufactured at CPI often

require very high skill in several machining disciplines to

complete, including turning, milling, wire electrical discharge

machining (EDM), sinker EDM, surface and cylindrical

grinding and other processes. The company relies heavily

upon the ability of its computer numerical control (CNC)

programming team to quickly produce programs for a wide

array of machines that produce quality parts the very first

time. In the past, the company was forced to use different

software packages to obtain the full range of required

capabilities for metal cutting and EDM.

More recently, Carbide Products has been using DP

Technology’s ESPRIT for its full range of programming

Carbide Products, Inc.

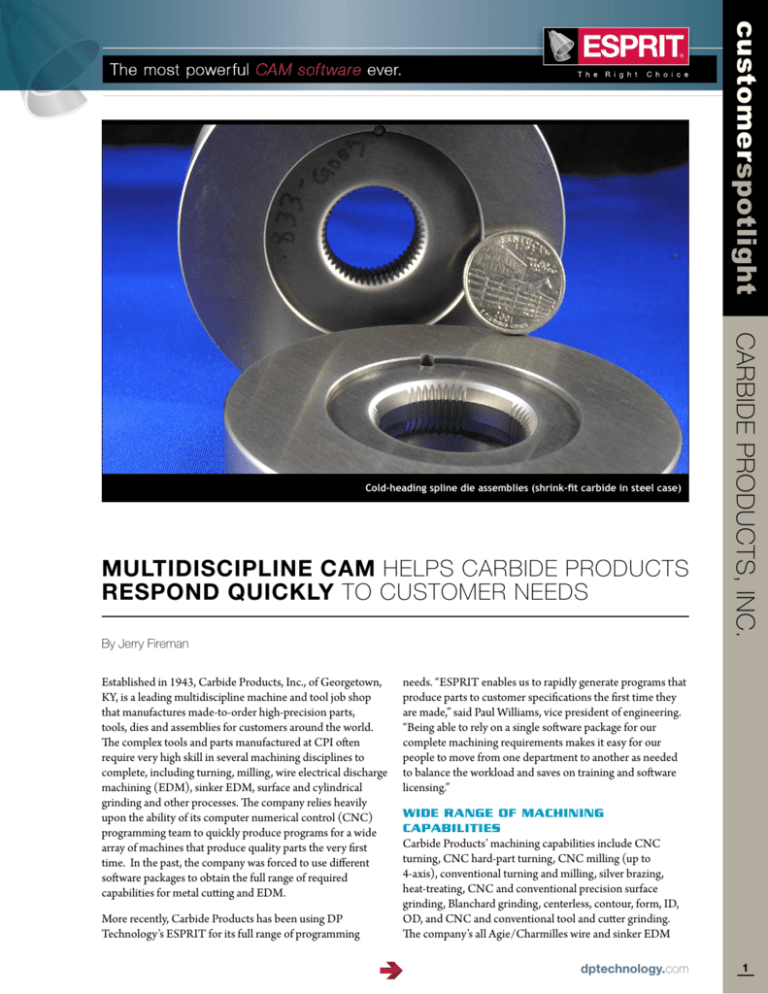

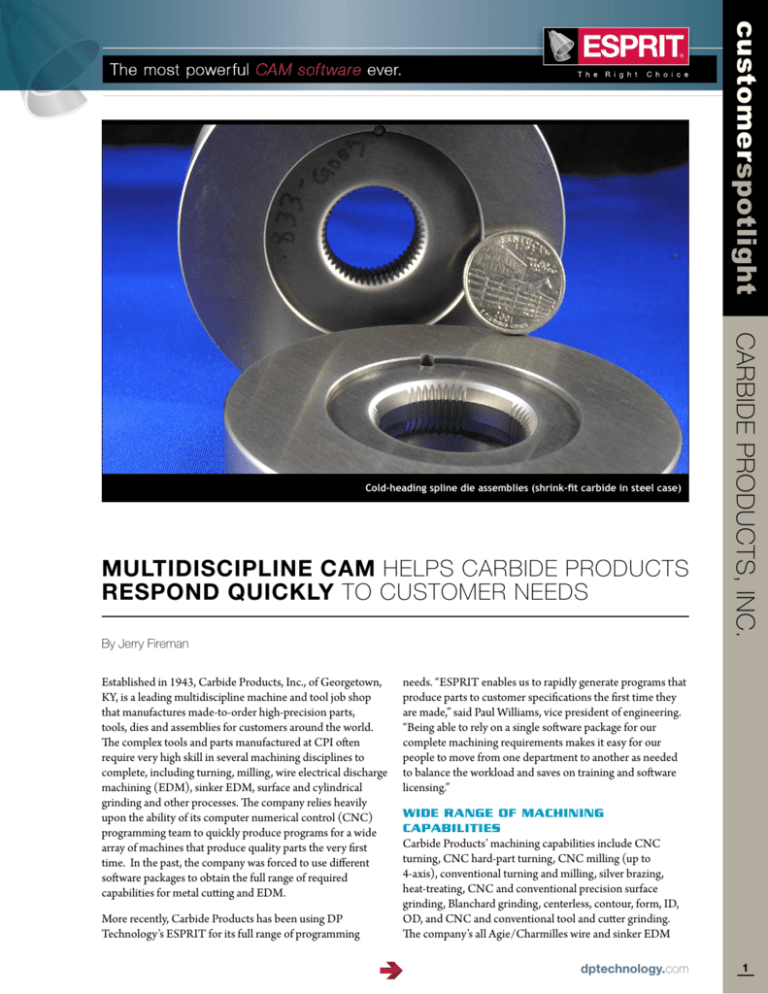

Cold-heading spline die assemblies (shrink-fit carbide in steel case)

needs. “ESPRIT enables us to rapidly generate programs that

produce parts to customer specifications the first time they

are made,” said Paul Williams, vice president of engineering.

“Being able to rely on a single software package for our

complete machining requirements makes it easy for our

people to move from one department to another as needed

to balance the workload and saves on training and software

licensing.”

Wide range of machining

capabilities

Carbide Products’ machining capabilities include CNC

turning, CNC hard-part turning, CNC milling (up to

4-axis), conventional turning and milling, silver brazing,

heat-treating, CNC and conventional precision surface

grinding, Blanchard grinding, centerless, contour, form, ID,

OD, and CNC and conventional tool and cutter grinding.

The company’s all Agie/Charmilles wire and sinker EDM

dptechnology.com

1

customerspotlight

department is capable of holding tolerances

to +/-0.00012” (3µm) and surface finishes

below 4 rms with no recast layer.

The vast majority of the company’s

production consists of special tooling that is

used to make other products; from machine

tools and power train components to peanut butter, pencils

and light bulbs. Production runs tend to be very short, often

just a single piece. The result is that the company does much

more CNC programming than most other companies of

the same size — and tolerances tend to be extremely tight,

often +/-0.0001 inch. The materials used by the company

tend to be costly, so it’s essential to get the program right

the first time. In the past, the company used several different

CNC programming systems in different areas such as EDM,

turning or milling. Programmers’ level of satisfaction varied

with the different programs. The use of multiple CNC

programs made it difficult to move programmers to help

out in an area that was particularly busy and increased the

complexity of training and administration.

CNC programming challenges

“When I first joined the company, we were much smaller

and I was able to handle all the programming by myself,” said

Ron Wainscott, EDM department supervisor for Carbide

Products. “As we grew, the programming task became more

than I could handle and today the EDM, lathe and mill

departments each have their own programmers. Our ability

to respond quickly to customer requests is critical to our

success.”

Carbide Products, Inc., of Georgetown, Kentucky

“We might have a customer call in today whose production is

down and needs a tool or machine part to get it restarted. We

will immediately begin programming the part and then go

right into production, and potentially have the part ready for

the customer in a couple of hours.”

“ESPRIT first came to our attention when we had problems

with our previous EDM software in programming a

new Mitsubishi machine,” Wainscott said. “Mitsubishi

recommended ESPRIT because many of their other

customers were using it successfully. We also heard good

things about ESPRIT from other machine shops that were

attending the International Machine Tool Show (IMTS). We

found that ESPRIT is capable of generating accurate posts

for the new machine and that it lends itself to fast turnaround

work. ESPRIT also provides a number of other valuable

features that were lacking on our previous programming

software. So we switched not just our EDM work but all of

our CNC programming to ESPRIT and have used it ever

since.”

Carbide Products, Inc.

The company machines a wide variety

of materials and material combinations,

including solid tungsten carbide, carbide

tipped, silicon carbide, silicon nitride, highspeed and tool steel, stainless steel, super

alloys, silver tungsten, copper tungsten,

samarium-cobalt rare-earth, cast iron,

other ferrous and non-ferrous alloys, heavy

metals, polycrystalline diamond (PCD),

polycrystalline cubic boron nitride (PCBN)

and plastics. All machining processes, as well

as heat-treating, brazing, assembly, inspection

and documentation are performed in-house

for total quality control.

ESPRIT’s full-spectrum functionality includes programming

for 2-5 axis milling, 2-22 axis turning, 2-5 axis wire EDM,

multitasking mill-turn machining, and B-axis machine tools.

“Being able to rely on a single software package for our complete

machining requirements makes it easy for our people to move from one

department to another as needed to balance the workload and saves on

training and software licensing.” -- Paul Williams, Carbide Products, Inc.

dptechnology.com

2

customerspotlight

A programmer at the helm of an Agie Progress Wire EDM machine

ESPRIT’s XY (lower), UV (upper) 4-axis contouring cycle

quickly programs parts with extremely complex tapers

or completely independent freeform shapes. The 4-axis

cutting process is automatically synchronized for any two

three-dimensional profiles and the programmer can add

an unlimited number of additional synchronization lines.

ESPRIT adds tabs automatically and creates skim cuts

for unattended machining. ESPRIT supports every make

and model of Agie EDM machine and fully exploits Agie

machine capabilities, including dual tapering, upper and

lower tapers, and advanced conics.

Electric motor stator die insert (solid carbide)

Programming for milling and

turning

Programming parts for milling and turning can be done

with the same user interface and following the same basic

workflow, which makes life easier for the programming

team. Lee Ross, milling department supervisor, said that

the programming of a part in his department also typically

begins with defining the geometry with ESPRIT based on

a paper drawing provided by the customer. He typically

adds grind stock and then defines the features in the part.

Carbide Products uses a combination of application-specific

machining in which the machining operation is defined for

the individual application and knowledge-based machining,

which involves reusing operations that have been optimized

for specific materials, geometries and tools.

The milling department has developed a library of machining

operations that include the tool and associated machining

parameters and can be simply dragged and dropped onto a

feature to create a toolpath. The ESPRIT KnowledgeBase™

provides detailed tool control and extensive process

automation, automatically choosing the most suitable

process to machine a given feature — including machining

cycles, cutting tools, speeds and feeds, and all associated

machining parameters. When a process is applied, process

steps are automatically adjusted to accommodate the feature

geometry and other feature characteristics. This saves time

by automating many tedious programming functions. The

KnowledgeBase™ also can help reduce machining cycle times

by providing programmers with standardized operations that

have been optimized by highly skilled and experienced

programmers.

Carbide Products, Inc.

EDM programming

Carbide Products typically receives

geometry from its customers in the form

of a DXF file or a paper drawing. A typical

EDM part made by Carbide Products

requires making five different internal angles

in a block of solid carbide and has tight

dimensional tolerances and tough surfacefinish requirements. The programmer opens

up ESPRIT and either imports the DXF file

or defines the geometry of the part using

ESPRIT’s computer aided design (CAD)

functionality. The programmer then defines

features in the part that normally correspond

to machining operations, such as pockets,

island, bosses and grooves. He or she creates

the draft features for the UV axis and applies

the toolpath to those features. This part is

then produced on one of the four Agie fouraxis wire EDM machines.

Regardless of the type of machine being programmed, the

next step is simulating the entire manufacturing process in

order to verify that the part produced by the program meets

the customer’s requirements. The programmer can view each

individual cut in the entire machining process in dynamic 3D

solids. ESPRIT also makes it easy to inspect the finished part

dptechnology.com

3

customerspotlight

by comparing the as-machined workpiece

to the original part design. Programmers

can zoom in on the simulated part to

determine whether or not it matches the

customer’s design. The simulation performs

a comparison of the toolpath with the solid

model and displays any part violations as

well as the amount of material remaining

using a customizable color format. The

simulation takes only a few seconds to

run but provides a highly effective way to

identify and fix programming problems

before they reach the shop floor.

Speed reducer drive component (steel)

DP Technology Corp.

1150 Avenida Acaso

Camarillo, CA 93012 USA

A programmer sets up a Haas 4-axis CNC mill

us nearly eliminate programming errors, which reduces

machine setup time and improves shop efficiency.” g

ON THE WEB:

www.carbidepros.com

Carbide Products, Inc.

“We use ESPRIT in nearly every aspect

of every process in our manufacturing

operations,” Williams concluded. “Its

advanced capabilities have helped us reduce

programming time and increase machining

productivity. We can now program the

most complicated parts in considerably less time than was

required in the past. ESPRIT’s knowledge base of machining

capabilities enable us to optimize machining operations

for cycle time improvements, store them in a library and

quickly apply them to features. The ability to create a realistic

simulation of the complete machining operation has helped

Laser LED reflector assembly (aluminum, delrin, stainless steel)

Phone: 1 800 627-8479

Outside the US: + 1 805 388-6000

Email: esprit@dptechnology.com

ESPRIT is a registered trademark of DP Technology Corp.

©2011 DP Technology Corp. All rights reserved.

dptechnology.com

4