Expert Systems with Applications 24 (2003) 73–77

www.elsevier.com/locate/eswa

Application of a hybrid genetic algorithm and neural network approach

in activity-based costing

Kyoung-jae Kima,*, Ingoo Hanb

a

Department of Management Information Systems, Kyung Hee Cyber University, 1 Hoegi-Dong, Dongdaemon-Gu, Seoul 130-701, South Korea

b

Graduate School of Management, Korea Advanced Institute of Science and Technology, 207-43 Cheongryangri-Dong, Dongdaemun-Gu,

Seoul 130-012, South Korea

Abstract

Activity-based costing (ABC) has received extensive attention since it achieves improved accuracy in estimating costs, by using multiple

cost drivers to trace the cost of activities to the products associated with the resources consumed by those activities. However, it has some

problems. The first problem is that ABC does not have general criteria to select relevant cost drivers. Second, ABC assumes linearity between

the uses of activities and the assigned quantities of indirect cost. When cost behavior shows a nonlinear pattern, conventional ABC may

distort product costs. This paper proposes hybrid artificial intelligence techniques to resolve these two problems. Genetic algorithms are used

to identify optimal or near-optimal cost drivers. In addition, artificial neural networks are employed to allocate indirect costs with nonlinear

behavior to the products. Empirical results show that the proposed model outperforms the conventional model.

q 2002 Elsevier Science Ltd. All rights reserved.

Keywords: Activity-based costing; Genetic algorithms; Artificial neural networks; Cost-driver optimization; Cost estimating relationships

1. Introduction

Cost allocation is a very important task involved in many

engineering and business decisions. In this sense, activitybased costing (ABC) has received extensive attention

during the past decade because it was developed for

overcoming the problems of the traditional costing system

through more a reasonable cost allocation process. Conventional ABC, however, has some problems to be resolved.

The first problem is that ABC does not have general criteria

to select relevant cost drivers. This problem is related to the

cost-drivers optimization (CDO) problem and associated

with the efficiency of costing systems. Second, conventional

ABC generally assumes a linear cost function. The linear

cost function is a function where the graph of total costs

versus a single cost driver forms a straight line within the

relevant range. Horngren, Foster, and Datar (1997) pointed

out that a cost function, in practice, is not always linear, but

sometimes shows nonlinear behavior. They described a

nonlinear function as a cost function where the graph of

total costs versus a single cost driver does not form a straight

line within the relevant range. In this aspect, conventional

* Corresponding author. Tel.: þ 82-2-968-0755; fax: þ82-2-968-0549.

E-mail address: kjaekim@hanmail.net (K. Kim).

ABC may distort product costs when a cost behavior shows

a nonlinear behavior. Thus, the second problem is

associated with cost estimating relationships (CERs), and

it is also related to the effectiveness of costing systems.

Prior researchers have endeavored to overcome these

problems of conventional ABC. Some of these studies

showed that the estimating performance of artificial neural

network (ANN) outperforms that of linear regression for

optimal cost allocation in ABC (Bode, 1998a,b; Creese &

Li, 1995; Garza & Rouhana, 1995; Lee, 1993; Lee & Ahn,

1993; Smith & Mason, 1997). Other studies proved the

efficiency of heuristic search techniques to select optimal

cost drivers (Babad & Balachandran, 1993; Levitan &

Gupta, 1996). However, they did not consider these two

problems simultaneously.

This study proposes a hybrid model composed of genetic

algorithms (GAs) and ANN to resolve the above two

problems of conventional ABC simultaneously. First, GA

portion of the model is proposed as an optimization method

of relevant cost drivers. Second, ANN portion of the model

is used to reflect a nonlinear cost function for the cost

allocation process. In the hybrid model, the GA globally

searches and seeks an optimal or near-optimal ANN

topology.

The paper is organized as follows: Section 2 reviews

0957-4174/03/$ - see front matter q 2002 Elsevier Science Ltd. All rights reserved.

PII: S 0 9 5 7 - 4 1 7 4 ( 0 2 ) 0 0 0 8 4 - 2

74

K.-j. Kim, I. Han / Expert Systems with Applications 24 (2003) 73–77

related prior studies. Section 3 presents a description of our

hybrid model of GA and ANN. In addition, Sections 4 and 5

describe the process of experiments and experimental

results. Finally, Section 6 discusses the conclusions and

the limitations of the study and future research issues.

2. Prior research

In general, traditional costing systems, volume-based

costing systems usually with a single cost driver, distort the

cost allocation process because they allocate costs by only

one criterion such as direct labor-hour, machine-hour, or

unit of production. Indirect costs, however, do not always

behave in proportion to the single cost driver in practice. In

addition, if cost drivers are not selected appropriately,

traditional approach does not accurately allocate indirect

costs to the products. This may cause distorted decisionmaking.

ABC is the costing method that assigns costs to activities

using multiple cost drivers, then allocates costs to products

based on each product’s use of these activities (Maher &

Deakin, 1994). ABC differs from traditional costing systems

in two ways (Cooper, 1989). Cost pools are defined as

activities rather than as production cost centers. In addition,

the cost drivers are used to assign activity costs to products,

which differs from traditional costing systems. ABC reduces

the risk of distortion because it uses multiple activities as

cost drivers based on CER.

There are two practical issues related to the proper

allocation of indirect cost for ABC systems. The first issue is

how to select proper cost drivers for cost allocation. It

focuses on the efficiency of ABC because optimal cost

drivers save the information-gathering cost without sacrificing major accuracy in cost estimation. It is a task currently

handled by application of human judgment for the purpose

of selecting appropriate cost drivers from the larger set of

available candidate drivers (Schniederjans & Garvin, 1997).

The second issue is how to determine the cost relationship.

It focuses on the accurate estimation of a cost function. It is

related to the effectiveness of ABC systems because

effectiveness can be achieved by the proper cost function

for cost allocation. Incorrect estimation of the cost function

will have repercussions in the areas of cost management and

control (Horngren et al., 1997).

Prior research has tried to resolve these two problems.

For the CDO problem, Maher and Deakin (1994) suggested

the following three criteria to select relevant cost drivers:

causal relation, benefits received, and reasonableness.

However, their criteria were abstract and subjective.

Babad and Balachandran (1993) attempted to optimize

cost drivers in ABC using greedy algorithms. They also

identified a priority order, according to which low-priority

and relatively insignificant activities with their associated

drivers would be combined to save costs without sacrificing

much accuracy in cost estimation. In addition, Levitan and

Gupta (1996) tried to optimize the selection of relevant cost

drivers using the GA in ABC systems. In their study, the GA

and the greedy algorithm are used to solve two cases from

the published literature. They concluded that a GA approach

achieved superior results to the greedy algorithm for both

cases. They found that the GA not only reduces informationgathering costs through fewer drivers, but also produces

more accurate costs even with fewer drivers.

A more recent study of Schniederjans and Garvin (1997)

proposed the combined analytic hierarchy process (AHP)

and zero –one goal programming to select relevant cost

drivers in ABC. They showed how the AHP approach could

bring consistency to the cost driver selection process. They

also illustrated how the AHP weighting can be combined in

the zero –one goal programming model to include resource

limitations in the cost driver selection process.

For the CERs, many researchers have made advances in

the cost allocation process. Several studies reported that

ANN outperforms linear regression for cost estimation

(Creese & Li, 1995; Garza & Rouhana, 1995; Lee, 1993;

Lee & Ahn, 1993). Smith and Mason (1997) suggested that

ANN has advantages when dealing with data for which there

is little a priori knowledge of the appropriate CER to select

for regression modeling. Bode (1998a) reported that ANN

after grouping of data outperforms linear and nonlinear

regression for cost estimation. He suggested that ANN

produces better cost predictions than conventional costing

methods when the following conditions are satisfied: a

sufficient case-base, known cost-driving attributes, few cots

drivers, and no explicit knowledge about cost effects. In

addition, Bode (1998b) suggested that ANN could be used

for R&D management. He carried out the estimation of final

cost of a new product under development, a typical R&D

management application, using ANN.

In this section, we describe prior studies which tried to

resolve the CDO and the CER problems in ABC systems.

However, they did not consider these problems simultaneously. There has been much research interest since these

two problems are interrelated for the estimation of product

costs. This study proposes the hybrid GA and ANN model to

resolve the CDO and the CER problems simultaneously.

Section 3 presents our research model.

3. The hybrid model of GA and ANN

The GA is a search algorithm based on survival of the

fittest among string structures (Goldberg, 1989). Recently,

the GA has been investigated and shown to be effective in

exploring a complex space in an adaptive way, guided by

the biological evolution mechanisms of reproduction,

crossover, and mutation (Adeli & Hung, 1995).

The first step of the GA is problem representation. The

problem must be represented in a suitable form to be

handled by the GA. Thus, the problem is described in terms

of genetic code, like DNA chromosomes. The GA often

K.-j. Kim, I. Han / Expert Systems with Applications 24 (2003) 73–77

works with a form of binary coding. If the problems are

coded as chromosomes, the populations are initialized. Each

chromosome within the population gradually evolves

through biological operations. There are no general rules

for determining the population size. But, population sizes of

100 –200 are commonly used in GA research. Once the

population size is chosen, the initial population is randomly

generated (Bauer, 1994). After the initialization step, each

chromosome is evaluated by a fitness function. According to

the value of the fitness function, the chromosome associated

with fittest individuals will be reproduced more often than

those associated with unfit individuals (Davis, 1994).

The GA works with three operators that are iteratively

used. The selection operator determines which individuals

may survive (Hertz & Kobler, 2000). The crossover

operator allows the search to fan out in diverse directions

looking for attractive solutions and permits chromosomal

material from different parents to be combined in a single

child. In addition, the mutation operator arbitrarily alters

one or more components of a selected chromosome.

Mutation randomly changes a gene on a chromosome. It

provides the means for introducing new information into the

population. Finally, the GA tends to converge on a nearoptimal solution through these operators (Wong & Tan,

1994).

The GA is usually employed to improve the performance

of artificial intelligence (AI) techniques. For ANN, the GA

is popularly used to select neural network topology

including optimizing relevant feature subsets, and determining the optimal number of hidden layers and processing

elements. The feature subsets, the number of hidden layers,

and the number of processing elements in hidden layers are

the architectural factors of ANN to be determined in

advance for the modeling process of ANN (Kim & Han,

2000). However, determining these factors is still part of the

art. These factors were usually determined by the trial and

error approach and the subjectivity of designer. This may

lead a locally optimized solution because it cannot

guarantee a global optimum.

In this paper, we propose the hybrid GA and ANN model

to resolve two problems of conventional ABC systems. In

this study, the GA is used for the step of selecting relevant

cost drivers and optimizing the network topology of ANN.

The GA globally searches an optimal or near-optimal ANN

topology in the hybrid model. The estimating process of the

hybrid model consists of the following three stages:

In the first stage, the GA searches (near-)optimal cost

drivers and the number of hidden nodes. The populations,

cost drivers and the number of hidden nodes, are initialized

into random values before the search process. The

parameters for searching must be encoded on chromosomes.

The encoded chromosomes are searched to optimize a

fitness function. The fitness function is specific to

applications. In this study, the fitness function is the average

deviation between expected and predicted values of product

costs. The parameters to be searched use only the

75

information about the training data. In this stage, the GA

operates the process of crossover and mutation on initial

chromosomes and iterates until the stopping conditions are

satisfied.

The second stage is the process of feed-forward

computation in ANN. In this stage, a sigmoid function is

used as an activation function. This function is a popular

activation function for the backpropagation neural network

because it can easily be differentiated. A linear function is

used as a combination function for the feed-forward

computation with selected cost drivers and ANN topology.

In the third stage, selected cost drivers and ANN

topology are applied to the holdout data. This stage is

indispensable to validate the generalizability because ANN

has the eminent ability of learning the known data. If this

stage is not carried out, the model may fall into the problem

of overfitting with the training data.

4. Research data and experiments

This study selects a revised case excerpted from Cooper

and Kaplan (1991) and Lee (1993). This is the case of Destin

Brass Products Co., which produces valves, pumps, and

flow controllers. The initial cost drivers (activities) are

‘Setup labor’, ‘Receiving’, ‘Materials handling’, ‘Engineering’, ‘Packing and shipping’, ‘Maintenance’, and

‘Machine usage’. The description of the research data is

as follows:

The possible production range of valves is 3500 – 10,500

products at intervals of 2000 products, that of pumps is

7500 – 17,500 at intervals of 1500 products, and that of flow

controllers is 2400 –5600 at intervals of 800 products. A

standard production unit for valves, pumps, and flow

controllers are 7500 products, 12,500 products, and 4000

products. If the number of valves is over 10,000 products,

then we put two units to the number of runs, otherwise put

one unit. In case of pumps, the number of runs increases by

one unit as the number of pumps increases by 2500 products

from the standard production. For flow controllers, standard

production runs are 10 units for 4000 products, and the

number of runs increases by two units as the number of

products increases by 800 products from the standard

production. The application rate is summarized in Table 1.

The following rules are applied for simulation of activity

values. For example, the value of the activity Setup labor is

calculated as 8 £ (the number of runs of valves) þ 8 £ (the

number of runs of pumps) þ 12 £ (the number of runs of

flow controllers). The application rate is presented in

Table 2.

Backpropagation algorithm and a sigmoid function are

used in ANN. The learning rate and momentum is 0.1, and

initial connection weight is 0.3 in ANN. Among the data,

60% of the data is training, 20% is testing, and 20% is

holdout data in order to avoid overfitting. The training and

testing data is used to search the optimal or near-optimal

76

K.-j. Kim, I. Han / Expert Systems with Applications 24 (2003) 73–77

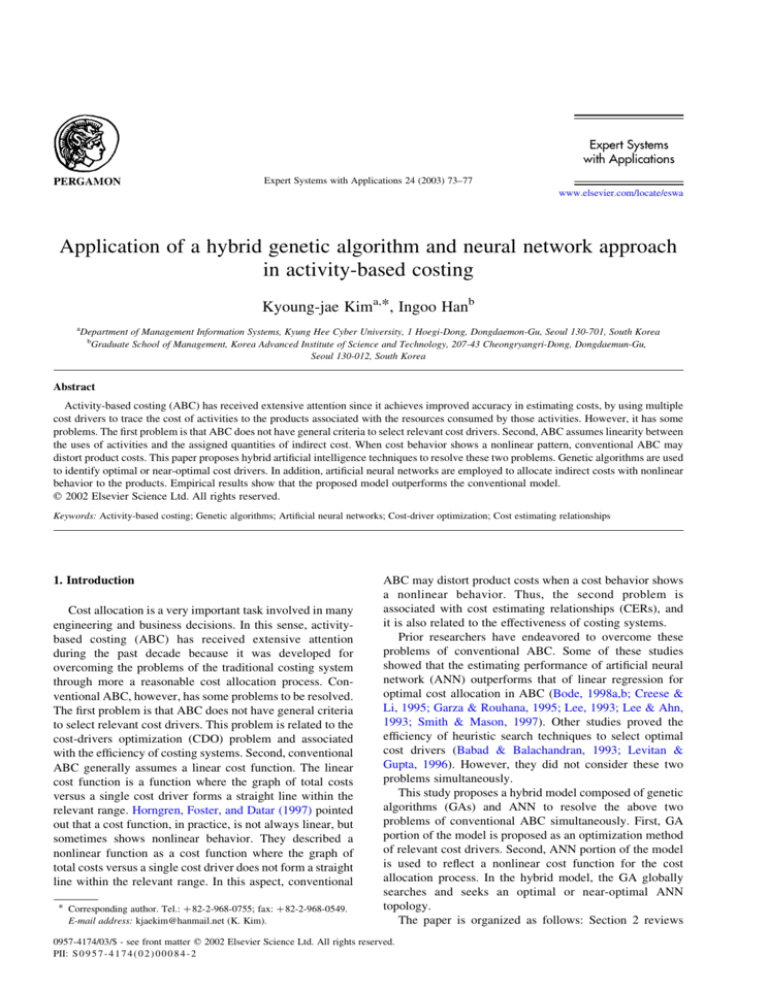

Table 1

Product summary and application rate (adapted from Cooper and Kaplan (1991) and Lee (1993))

Standard production (number of run)

Application rate

Valves

Pumps

Flow controllers

7500 products (1 run)

If products . 10,000,

then run ¼ 2, else, run ¼ 1

12,500 products (5 runs)

If products þ 2500 (or 22500),

then run þ 1 (or 21)

4000 products (10 runs)

If products þ 800 (or 2800),

then run þ 2 (or 22)

Table 2

Indirect cost activity analysis and application rate (adapted from Cooper and Kaplan (1991) and Lee (1993))

Activity

Application rate for valves

Application rate for pumps

Application rate for flow controllers

Setup labor

Receiving

Materials handling

Engineering

Packing and shipping

Maintenance

Machine usage

Number of runs £ 8

Number of runs £ 4

Number of runs £ 4

2

1

Number of products/2

Number of products/2

Number of runs £ 8

Number of runs £ 5

Number of runs £ 5

3

7

Number of products/2

Number of products/2

Number of runs £ 12

Number of runs £ 10

Number of runs £ 10

5

22

Number of products/5

Number of products/5

Table 3

Accuracy for cost allocation (MAPE)

No. of hidden nodes

3

3

7

7

No. of training patterns

presented since minimum

average error of the

test data is recorded

50,000

100,000

50,000

100,000

Training data

Holdout data

Conventional ANN

(7 drivers)

Hybrid model

(4 drivers)

Conventional ANN

(7 drivers)

Hybrid model

(4 drivers)

0.881

0.871

0.866

0.809

0.905

0.848

0.855

0.809

1.426

1.492

1.317

1.400

1.358

1.295

1.271

1.246

parameters and is employed to evaluate the fitness function.

The holdout data is used to test the results with the data that

is not utilized to develop the model. Using 125 data items,

we train and validate the hybrid model of GA and ANN and

the conventional ANN model. In addition, 50,000 and

100,000 training patterns are presented to ANN since

minimum average error of the test data is recorded. For the

controlling parameters of the GA search, the crossover and

mutation rates vary to prevent ANN from falling into a local

minimum. The crossover probabilities and probability of

mutation are 0.7 and 0.1.

5. Experimental results

For validating the proposed model, 25 holdout data items

are used. After experiments, the GA selects four cost drivers

including Receiving, Materials handling, Maintenance, and

Machine usage from all seven drivers. In addition, the GA

recommends three hidden nodes in ANN. Table 3 presents

mean-absolute-percent-error (MAPE) by different experimental conditions.

The results show that the proposed hybrid model

consistently outperforms conventional ANN, regardless of

changes in the number of hidden nodes and the number of

learning patterns. Although the hybrid model uses fewer

cost drivers than conventional ANN, it produces higher

accuracy in allocating indirect costs.

6. Concluding remarks

This study has proposed the hybrid AI model to resolve

the problems of designing ABC systems. In this study, the

GA was used for the step of selecting relevant cost drivers

and optimizing the network topology of ANN. The GA

globally searched an optimal or near-optimal ANN topology

in the hybrid model. The proposed model outperformed the

conventional model. From the experimental results, we

concluded that the proposed model has advantages when the

model analyzes the data with complex and nonlinear CER.

K.-j. Kim, I. Han / Expert Systems with Applications 24 (2003) 73–77

The major advantage of the proposed model was simultaneous consideration of efficiency and effectiveness issues

for designing ABC systems.

However, this study had some limitations. In this study, a

simulated data based on a real-world case was used for

testing the proposed model. This study cautiously managed

the simulation process, but the results on simulated data

might not guarantee consistency in the real world. Thus, it is

necessary to test the proposed model with the real-world

data. In addition, while ANN performed well with the GAbased optimization, other learning algorithms might also

prove effective in place of ANN. We believe that there is

great potential for further research with the optimization

using the GA for other AI techniques including case-based

reasoning and support vector machines. For future work, we

intend to apply the proposed model to more complicated

areas in accounting including cost estimation, cost allocation to specific departments, and the mitigation of the

linear assumption in cost-volume-profit (CVP) analysis.

References

Adeli, H., & Hung, S. (1995). Machine learning: Neural networks, genetic

algorithms, and fuzzy systems. New York: Wiley.

Babad, Y. M., & Balachandran, B. V. (1993). Cost driver optimization in

activity-based costing. The Accounting Review, 68(3), 563 –575.

Bauer, R. J. (1994). Genetic algorithms and investment strategies. New

York: Wiley.

Bode, J. (1998a). Neural networks for cost estimation. Cost Engineering,

40(1), 25–30.

Bode, J. (1998b). Decision support with neural networks in management of

research and development: Concepts and application to cost estimation.

Information and Management, 34(1), 33–40.

Cooper, R. (1989). The rise of activity-based costing—Part Three: how

many cost drivers do you need, and how do you select them? Journal of

Cost Management, 2(4), 34– 46.

77

Cooper, R., & Kaplan, R. S. (1991). The design of cost management

systems. New Jersey: Prentice-Hall.

Creese, R. C., & Li, L. (1995). Cost estimation of timber bridges using

neural networks. Cost Engineering, 37(5), 17–22.

Davis, L. (1994). Genetic algorithms and financial applications. In G. J.

Deboeck (Ed.), Trading on the edge (pp. 133–147). New York: Wiley.

Garza, J. M., & Rouhana, K. G. (1995). Neural networks versus parameterbased applications in cost estimating. Cost Engineering, 37(2), 14– 18.

Goldberg, D. E. (1989). Genetic algorithms in search, optimization, and

machine learning. Reading, MA: Addison-Wesley.

Hertz, A., & Kobler, D. (2000). A framework for the description of

evolutionary algorithms. European Journal of Operational Research,

126(1), 1–12.

Horngren, C. T., Foster, G., & Datar, S. (1997). Cost accounting: A

managerial emphasis. New Jersey: Prentice-Hall.

Kim, K.-j., & Han, I. (2000). Genetic algorithms approach to feature

discretization in artificial neural networks for the prediction of stock

price index. Expert Systems with Applications, 19(2), 125 –132.

Lee, J. K. (1993). Total cost prediction models using artificial neural

networks. Master thesis. Suwon, South Korea: Ajou University.

Lee, J. S., & Ahn, T. S. (1993). An artificial neural network approach for

activity-based cost allocation. Proceedings of the 1993 Korea– Japan

Joint Conference on Expert Systems, Seoul, South Korea: Korea Expert

Systems Society, pp. 380 –393.

Levitan, A., & Gupta, M. (1996). Using genetic algorithms to optimize the

selection of cost drivers in activity-based costing. International Journal

of Intelligent Systems in Accounting, Finance and Management, 5(3),

129– 145.

Maher, M. W., & Deakin, E. B. (1994). Cost accounting. Burr Ridge,

Illinois: Irwin.

Schniederjans, M. J., & Garvin, T. (1997). Using the analytic hierarchy

process and multi-objective programming for the selection of cost

drivers in activity-based costing. European Journal of Operational

Research, 100(1), 72– 80.

Smith, A. E., & Mason, A. K. (1997). Cost estimation predictive modeling:

Regression versus neural network. The Engineering Economist, 42(2),

137– 160.

Wong, F., & Tan, C. (1994). Hybrid neural, genetic, and fuzzy systems. In

G. J. Deboeck (Ed.), Trading on the edge (pp. 243 –261). New York:

Wiley.