Dr. Jamal Al

advertisement

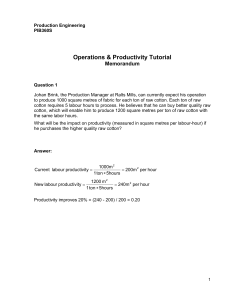

Dr. Jamal Al-Zayer OM 210 ASSIGNMENTS AND HOMEWORK First semester 081 (20008-2009) Chapter 1 HW # 1Problem 1.6 Page 21 Problem 1.9 Page 22 Problem 1.10 Page 22 Internet Homework Problem Case Study Page 23 Chapter 2 HW # 2 Search and Submit Case Studies Refer to Page 50 for internet search P Chapter 4 HW # 3 Problem 4.1 Page 142 Problem 4.5 Page 142 Problem 4.6 Page 143 Problem 4.9 Page 143 Problem 4.24 Page 145 HW # 4 Problem 4.41 Page 148 HW # 5 Case Study Internet Homework Southwestern University Page 151 Chapter 5 P HW # 6 Problem 5.10 Page 186 Problem 5.15 Page 187 Problem 5.16 Page 187 HW # 7 Problem 5.1 1Page 186 Chapter 6 Managing Quality HW # 8 Problem 6.16 Page 215 HW # 9 Internet Homework Problem Case Study Page 215 HW # 10 Internet Search about Quality Issues to be Submitted Quality Supplement HW # 11 Problem 6.6 Page 245 Problem 6.8 Page 245 Problem 6.10 Page 246 Problem 6.1 1 Page 246 Problem 6.20 Page 247 Use the POM Software to Solve the above problems HW # 12 Problem 6.34 Page 249 Use POM e H W # 13 Internet Homework Case Study Page 250 H W # 14 Internet homework Case Study Page 251 Alabama Airlines Chapter 7 Capacity Planning H W # 15 Problem Problem Problem Problem Problem 7.9 Page 303 7.27 Page 305 7.22 Page 304 7.28 Page 305 7.33 Page 306 HW # 16 Internet Case Presentation Page 307 Chapter 8 Location Strategies H W # 19 Problem 8.5 Page 330 Problem 8.9 Page 331 Problem 8.16 Page 333 Problem 8.14 Page 332 Problem 8.20 Page 333 Problem 8.21 Page 334 HW # 20 Problem 8.25 Page 335 H W # 21 Internet Case Study Southern Recreational Vehicle Company Page 336 H W # 22 Internet Video Case Study Where to Place Hard Rock's Next Cafe Additional Material and Handout Sample Problems Given to the Students Dr. Jamal Al-Zayer First Semester 08 1 OM 210 Practice Problems: Chapter 1, Operations and Productivity Problem 1: Mance Fraily, the Production Manager at Ralts Mills, can currently expect his operation to produce 1000 square yards of fabric for each ton of raw cotton. Each ton of raw cotton requires 5 labor hours to process. He believes that he can buy a better quality raw cotton, which will enable him to produce 1200 square yards per ton of raw cotton with the same labor hours. What will be the impact on productivity (measured in square yards per labor-hour) if he purchases the higher quality raw cotton? Problem 2: P' C. A. Ratchet, the local auto mechanic, finds that it usually takes him 2 hours to diagnose and fix a typical problem. What is his daily productivity (assume an 8 hour day)? Mr. Ratchet believes he can purchase a small computer trouble-shooting device, which will allow him to find and fix a problem in the incredible (at least to his customers!) time of 1 hour. He will, however, have to spend an extra hour each morning adjusting the computerized diagnostic device. What will be the impact on his productivity if he purchases the device? Problem 3: Joanna French is currently working a total of 12 hours per day to produce 240 dolls. She thinks that by changing the paint used for the facial features and fingernails that she can increase her rate to 360 dolls per day. Total material cost for each doll is approximately $3.50; she has to invest $20 in the necessary supplies (expendables) per day; energy costs are assumed to be only $4.00 per day; and she thinks she should be making $10 per hour for her time. Viewing this from a total (multifactor) productivity perspective, what is her productivity at present and with the new paint? P' Problem 4: How would total (multifactor) productivity change if using the new paint raised Ms. French's material costs by $0.50 per doll? Problem 5: If she uses the new paint, by what amount could Ms. French's material costs increase without reducing total (multifactor) productivity? ANSWERS: Problem 1: Current labor productivity = New labor productivity 1000 sq yds = 200 sq yds per hour 1 ton*5 hours 1200 sq yds = 240 sq yds per hour 1 ton * 5 hours = Productivity improves 20% = ( 240 - 200 ) / 200 = .2 C4 Problem 2: Current productivity = 8 hours per day = 4 problems per day 2 hours per problem Productivity with computer = Productivity improves 75% 7 hours per day = 7 problems per day 1 hour per problem 7-4 4 3 4 Problem 3: Currently Using the new paint Labor 12 hrs * $10 = $120 12 hrs * $10 = $ 120 Material 240 * $3.50 = $840 360 * $3.50 = $1260 Supplies = $ 20 =$ 20 Energy =$ 4 =$ 4 Total Inputs = Productivity 2401984 $984 = 0.24 = $1404 360/1404 = .26 Problem 4: If the material costs increase by $0.50 per doll: Using the new paint Labor 12 hrs * $10 = $ 120 Material 360 * $4.00 = $1440 Supplies =$ 20 Energy =$ 4 Total Inputs = $1584 Productivity 36011 584 = 0.23 Problem 5: From the answer to Problem 3 we know the following: Currently Using the new paint Labor 12 hrs * $10 = $120 12 hrs * $10 Material 240 * $3.50 = $840 360 * $3.50 = $120 = $1260 Supplies = $ 20 =$ 20 Energy =$ 4 =$ 4 Total Inputs = $984 = $1404 Productivity 2401984 = 0.24 36011404 = -26 We want to know how high the material cost could go, using the new paint, before the productivity drops to the current level of 0.24. In mathematical terms we make the material cost a variable (4,set the new multifactor productivity value to the current level, 0.24, and solve for x. It follows then that the new paint could raise Materials cost by no more than approximately $0.27 (the difference between $3.77 and $3.50) before Ms. French would experience a decrease in multifactor productivity. Practice Problems: Chapter 6, Managing Quality Problem 1: The accounts receivable department has documented the following defects over a 30-day period: _ . -----Invoice number and invoice referenced do not agree - : - I --* "~..." - - -.--- I - i 12 I I I ( What techniques would you use and what conclusions can you draw about defects in the accounts receivable department? Problem 2: Prepare a flow chart for purchasing a Big Mac at the drive-through window at McDonalds. Problem 3: Draw a fishbone chart detailing reasons why a part might not be correctly machined. ANSWERS: Problem 1: Use a Pareto chart to organize the defects and conclude that the obvious problem (about half the defects) is the failure of the check to agree with the company's records as to the correct amount. Other problems are late payments and an apparent invoice-filing problem in the office. Notice that 27% of these common errors appear to be the result of procedural problems within accounts receivable (invoice not on record, no invoice issued, and invoice numbering problems). This value could be considerably higher depending on how much of the problem of disagreement between invoice and check amounts is the result of accounts receivable process problems. Problem 2: - ) Distance Symbol - -- - Activity - - -. . -. - .- - 7 - -- - - Pull up to speaker - - .. . - -.--- - - -- - .- Press button Wait for response -- -- -- - - - -- Verbalize order - - - - - - - - - -- - - --- Get confirmation of order and cost --- -----Move car up in line -- - --- Wait --- . . - - - Move car up in line Wait Verify order and cost -- -- -- - Pay and receive order --.- - .. - Leave ---- ---- - --- - - -- -- - .----- Realize they forgot the extra catsup! ------.---" Problem 3 Concern Factors Machinery Manpower Material Method

![[Agency] recognizes the hazards of lead](http://s3.studylib.net/store/data/007301017_1-adfa0391c2b089b3fd379ee34c4ce940-300x300.png)