Quality Assessment Monitors - State Laboratory of Public Health

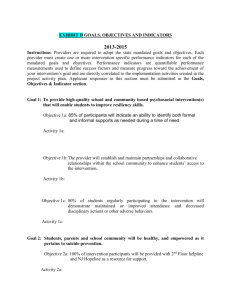

advertisement

October 2012 | Vol. 8, Issue #3 Quality Assessment Monitors The previous two issues of this year’s Management Bulletin have discussed the basic principles of Quality Assessment (QA) and how to organize a QA team. In this issue, we will discuss how to select and implement monitors or quality indicators that will assess the laboratory’s quality systems. For a laboratory to have an effective and efficient QA plan, it must first identify the key aspects of the laboratory’s performance and services that warrant ongoing monitoring. Some monitors are required by regulatory agencies, some are known “problem” areas, and some quality indicators are monitored because they are critical steps in a process. Most importantly, the laboratory must choose various indicators that monitor all phases of the total testing process as well as the general laboratory system. Why Monitor the Laboratory Quality Systems The main goal of a laboratory’s QA program is to prevent errors before they occur. Monitoring key quality indicators allows management and the QA team to identify where errors are occurring or have the potential to occur. The team can focus their attention to these areas to develop a corrective action plan that will result in quality improvement. Monitoring the laboratory quality systems is a requirement of regulatory agencies, accrediting organizations and contractual arrangements. The Clinical Laboratory Improvement Amendments (CLIA) ’88 § 493.1200 states: Each laboratory that performs nonwaived testing must establish and maintain written policies and procedures that implement and monitor a quality systems for all phases of the total testing process (that is, preanalytic, analytic, and postanalytic) as well as general laboratory systems. (b) The laboratory’s quality systems must include a quality assessment component that ensures continuous improvement of the laboratory’s performance and services through ongoing monitoring that identifies, evaluates and resolves problems. The North Carolina State Laboratory of Public Health (NCSLPH) CLIA Contract Program states that: “The laboratory must establish and maintain a written QA plan that provides an ongoing mechanism for monitoring and assessing laboratory activities. …” The key word is “monitor” which means to measure and to assess. Monitoring is simply a way for the laboratory to quantify how well they are performing by measuring specific quality indicators that are designed to detect errors or potential errors in a process. That is why it is critical for the laboratory to customize and choose key quality indicators that monitor the integrity of the entire testing process. Selecting What Quality Indicators to Monitor As previously stated, quality indicators can be designed to measure any aspect of the laboratory quality systems. When the QA team is deciding what quality indicators to monitor, it should evaluate where the laboratory is at the highest risk for potential errors to occur. It should also look at steps in processes to determine which are most critical. A critical step is a step that, if missed or incorrectly performed, has the potential to cause harm or even death to a patient or employee. An indicator should be well defined, practical and have a realistic action threshold. It should provide valuable information that leads to change and continuous improvement. Poorly designed indicators or continuously monitoring an indicator that has been determined as stable is not only a waste of valuable time and resources, but can also result in confusing or misleading information. Below is a list of examples of quality indicators that a laboratory could choose to monitor. • • • • Preanalytic process indicators: Patient identification. Completeness and accuracy of sample requisitions/orders. Sample collection and labeling. Sample storage and transport. Analytic process indicators: QC performance and corrective actions. Instrument comparisons. PT performance and corrective actions. Postanalytic process indicators: Complete and accurate test reports. Critical value reporting. Stat turnaround time. General Laboratory System: Complaint investigation. Personnel competency. Personnel safety. Selecting good quality indicators to monitor is the first step in developing a well-defined QA plan. Next, the QA team will need to determine action thresholds or target values. Determining Action Thresholds or Target Values An action threshold or target value simply states “what are we trying to accomplish?” and “when do we need to take action?” It is, in most cases, a numerical value assigned to a quality indicator that, when exceeded, indicates that a process is failing and the laboratory needs to take further action and investigate why it is failing. When establishing an action threshold or target value, the laboratory must determine the feasibility of the target and whether it actually improves the quality of patient safety, patient care or laboratory service. For example, a laboratory implements in their QA plan that 100% of all patients will be correctly identified. Is this action threshold feasible and does it improve the quality of patient care and/ or safety? Absolutely! Correctly identifying a patient is a critical step in the preanalytic process. One patient identification error could result in patient harm or in worst case scenario, death. Once the team has assigned action thresholds or target values to the selected indicators, the next step is to determine how the information will be collected. Collection of the Data How frequently should a lab monitor its quality indicators? CLIA recommends at least once a year. Is this always sufficient? Yes, no, maybe. The lab will need to review data to determine if the indicator is a known “problem” area, a critical step in a process that needs constant monitoring, or a relatively stable indicator that requires only periodic monitoring. Once frequency has been determined, the team will need to determine how the data will be collected. The team must decide what tools they will use to collect the data. They can develop forms, checklists or logs that would aid in the collection of the data. In larger facilities, computer programs or document control systems can be purchased that collect, evaluate and report the data. Once the team decides which tool(s) will be used to collect the information, they will need to designate a person who will be responsible for performing the monitor. The person that the team selects to perform the monitor should be someone who has an understanding of how the laboratory functions and is able to collect and present the data without bias. The data collected should not be presented in a negative context, nor should the data be purposely skewed to make it appear that the lab is performing better than it is. Instead, should be presented in a way that is both educational and informative. The information collected should be viewed as a positive way for the laboratory to take an internal look at itself to see what is working and what is not working. The overall goal of QA is to ensure that the laboratory is always in a state of continuous quality improvement. Once the information has been collected, it will need to be evaluated to see what corrective action, if any, needs to be taken to improve the process When to Take Action The data must be evaluated to see what type of action will need to be taken. The team will need to decide if a QA study is required or if the data reveals a problem that is just developing? When should a QA study be initiated? When a significant problem or error has been identified, then it is necessary to initiate a QA study. How do we determine if an error or problem is significant? A problem or error is significant when the lab is performing well below its established action threshold or the problem is widespread, trending, reoccurring or the error has the potential to cause harm or has caused harm to a patient or employee. In some cases the data may indicate that there is a problem developing. In this case, the team may not need to initiate a formal QA study, but may need to document that this indicator will be monitored more frequently to see if a trend is developing. Once it has been determined what action is required, the team must document the action plan in its entirety. Document, Document, Document! Documentation is crucial in the QA monitoring process. The first questions that an inspector will ask are, “Do you have documentation that your lab monitors it’s quality systems?” and “Do you have documentation of what corrective action and followup was taken when errors were detected?” The QA team will need to document the findings of the investigation when a problem or error was detected during monitoring. They will need to document the plan of action that was implemented to improve the process. And last but not least, the team will need to document its plan for follow-up. This should include a timeframe for the indicator to be reassessed to see if the plan of action was effective. Without documentation, the laboratory does not have evidence to prove that they have implemented a QA plan that effectively monitors and assesses the laboratory’s quality systems. Communication It is vital that the team communicates the outcome to all individuals involved in the QA process to include lab staff and the facility. In cases where the plan was not effective, soliciting feedback will afford everyone an opportunity to suggest ideas on how to improve the process. QA is everyone’s responsibility. Summary Developing key quality indicators that monitor the integrity of the laboratory quality system is essential in developing an effective and efficient QA plan. On-going monitoring, improving processes, follow-up and communication are all integral parts of a well-defined QA plan that is committed to continuous quality improvement. April Hill, MLS (ASCP) cm References: 1. Federal Register 42 CFR Part 493 Clinical Laboratory Improvement Amendments (CLIA) (Accessed August, 2012) 2. Sharon S. Ehrmeyer, Ph.D. ,Westgard QC, Inc., 2012, The New Poor Lab’s Guide to the Regulations. 3. Clinical and Laboratory Standard Institute, 2010, GP35-A Development and Use of Quality Indicators for Process Improvement and Monitoring of Laboratory Quality; Approved Guidelines. 4. LABMEDICINE, Volume 39 number 2, February 2008, Benchmarking Laboratory Quality. (Accessed August 2012) 5. Lab Medicine, 2010, Evaluating Laboratory Performance with Quality Indicators. , (Accessed August 9,2012) 6. April Hill, Quality Assessment Study, January 20, 2012.