2012 ANNUAL REPORT

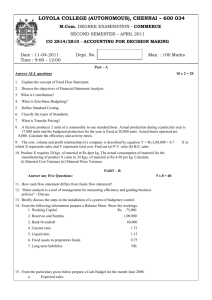

advertisement