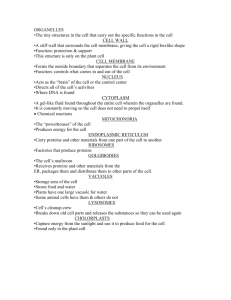

Functional Properties of Proteins

advertisement