Case Study Grand Canyon University Event Center

advertisement

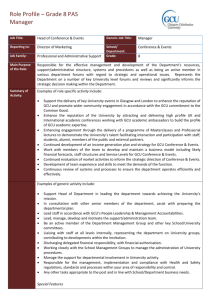

Grand Canyon University Event Center Phoenix Sports Arena Requires Team Coordination TDIndustries Uses MISOP, BIM and Pre-Fab to Deliver Located in the heart of Phoenix, Arizona, Grand Canyon University (GCU) is a premier, private Christian university. GCU’s event center is a 135,000-squarefoot facility with a 5,000-seat arena that will host men’s and women’s basketball, national conferences, concerts and events. The $40 million venue is the crown jewel of GCU’s expansion plans to accommodate a growing student body at its Camelback Road campus. THE FACE OF INNOVATION tdindustries.com Case Study The Situation GCU’s goals for its event center were two-fold: 1) to enhance the on-campus experience for its students; and 2) to provide the greater Phoenix area with a top-notch entertainment and sports venue that would raise GCU’s profile in the community. GCU selected Tempe-based Architekton as architects and wanted a design that was unlike other structures in the Valley. Architekton partnered with Kansas City-based 360 Architecture to design a unique facility that would accommodate both the loud, raucous environment of basketball games, as well as capture the acoustic mood of a concert or lecture. GCU selected Perini Building Company of Phoenix as the general contractor. Perini selected TDIndustries in Phoenix to provide Design/Assist MEP services during the design phase and construction. The construction schedule was challenging with a start date of July 2010 and completion date of August 2011. The Solution TD’s entire team was involved in this Design/Assist project. In addition to using Building Information Modeling (BIM) technology, TD’s Building Systems Integration (BSI) group designed and implemented a customized integration system utilizing a Tridium® management and control platform for the HVAC system. The integration system also incorporates a Delta Controls package installed by Arizona Control Specialists, Inc. that can be utilized for other systems such as lighting, security, fire, and safety. TD also used its proprietary MISOP (Mentally Installed Systems on Paper) throughout the construction phase and relied heavily on its pre-fabrication shop for plumbing and piping components. Some of the systems built were: • HVAC systems that included two 275 ton chillers, 11 air handlers with VAV and fan powered boxes, along with 22 fan coil units to meet heating and cooling requirements; • Two fan wall arrays were added to accommodate pyrotechnic displays. Each array consists of 16 individual fans working in concert to remove smoke during pyrotechnic displays; and • A customized system design and equipment installation to meet evacuation requirements while maintaining an acceptable noise criteria level (sound level). The Success TD’s proactive planning and schedule development allowed the construction team to improve the project end date by 45 days. This accelerated schedule led to the issuance of a Temporary Certificate of Occupancy two weeks earlier than planned. In addition to the earlier completion date, the TD team had no lost time accidents on the project. The facility will provide a first class sports and entertainment venue that will benefit both GCU and the community.