BRONZE~THE "LOST WAX" CASTING FOUNDRY PROCESS

advertisement

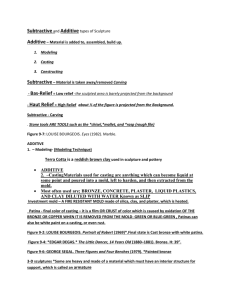

BRONZE~THE "LOST WAX" CASTING FOUNDRY PROCESS Bronze Art Foundry Process Bronze, an alloy of copper and tin, first appeared in the Near East toward the end of the fourth millennium B.C., and there is no accurate record of when the lost wax method of casting was first utilized. It is believed the earliest users of the method began with a clay core roughly the shape of the subject to be sculpted. This core was covered with wax, and then sculpted to the finished form. Once the wax hardened it was covered with clay. The object was baked, hardening the clay and melting the wax. Because the wax melted out into the bottom of the baking receptacle or oven, it was unusable or lost - hence the process is called "Lost Wax." The space evacuated by the wax was then filled with molten bronze. Once the bronze cooled and hardened, the clay was removed and the remaining bronze cleaned and polished. Similar to photography, an final image is developed through the use of negatives and prints. In bronze casting, negatives are molds, and the prints are the castings. The basic principle of the process has remained unchanged, although many new techniques have been developed. The most significant of which was the use of molds from which many waxes could be made. As opposed to cold cast bronze (a plastic-based product with metal flecks imbedded) , Lost Wax cast bronze is a permanent medium. Archeologists have found pieces that were buried in the earth or preserved in seawater for thousands of years. Art by Knight feels a strong sense of responsibility when creating art that will survive many generations; therefore we only cast in foundries that are well established with veteran craftsmen that use the traditional methods described below. In viewing these steps you will gain an appreciation for the tremendous amount of labor and skill required to produce a fine art bronze. You will also gain an understanding of how a masterful sculptor interacts with the foundry and their artisans. The Original Sculpture A master mold maker will study the completed sculpture. A determination is made on how the sculpture will be sectioned or "laid up" for mold making. Complex molds will require the original artwork to be cut into smaller manageable pieces. Mold making is by far the most critical step of the procedure. The detail of the original must be captured and transferred in the mold. If not, they will be difficult, if not impossible, to replace in any other step. The original sculpture rarely survives the mold making process so the details captured and the quality of the mold is absolutely critical. An accomplished sculptor is knowledgeable of the entire casting process. Knowing what is required at the foundry can affect sculpting decisions such as what internal armature materials are best to help support the sculpture while facilitating the mold making process. A multitude of design decisions in creating the original sculpture must be made that can either help or hinder the entire casting process. In creating design, a sculptor must be aware of how the final bronze will be supported from its own weight in the final casting, and provide proper support while remaining true to the concept of the art. There are numerous areas in the creation of a complex fine art sculpture, where difficult decisions must be made. These determinations can be facilitated by a master sculptor who understands the foundry steps, and can achieve the same desired effect, while keeping the extensive and intricate casting process in mind. This results in a final casting that is a marriage of talent between the sculptor and the foundry artisans. Mold Making The sculpture is first sealed and then a release agent is applied to allow for easy removal of the rubber mold. Depending on the artist's requirements, they will create a silicone, latex, or polyurethane mold. When the original sculpture has been prepared, the first coat of rubber is applied by hand. This is very important to obtain the highest level of detail. The mold maker must ensure the entire sculpture is covered with an even, thin layer of rubber. Once the rubber has set, additional coats must be applied with “keys.” These keys will identify the proper position of the mold when closed. When the rubber is thoroughly set, a backup shell or "Mother Mold" is applied, to support the rubber for the wax pouring process. This shell is normally made from plaster or fiberglass. If using a plaster mold, a plaster mixture is brushed on and strengthened with hemp. A fiberglass mold has proven to be most suitable for artisans to work with. It is durable yet lighter than plaster. One half of the piece is completed, allowed to dry, and then flipped over to complete the other half. The mother mold is separated and the rubber gently pulled back so the original sculpture can be removed. The rubber is then cleaned of any remaining particles from the original. It is now ready to receive the wax. Now that the mold has been created and is cleaned and prepped, it is a perfect "negative" of the original sculpture. From the negative rubber mold, a positive wax casting is created. Wax Pouring The completed mold, having already been prepped, is now ready for the wax. The mold is separated and the first coat of wax is painted into the mold to capture all the fine details of the artist's work. The mold is put together and more wax is poured in. It is then rotated until an even, thin coating is achieved. Once it has cooled, a second coat is applied and rotated to achieve a thickness of 1/8 to 3/16 of an inch. 3 to 5 coats are normally used. The excess wax is poured out. After the wax has completely cooled, the mother mold and rubber mold are removed. Now the wax casting is revealed. It is at this stage, especially on the first wax, that the sculptor often inspects the wax to make sure that it is true to the original sculpture. The wax is now the first positive image of the original art. It is the wax, that carries all the form and detail into the final bronze casting. Wax Chasing and Spruing After all the seam lines are removed, wax is used to fill holes and repair any defects resulting from air bubbles in the wax pouring operation. Wax rods are attached to the sculpture. These rods are called sprues or gates. A large cup is attached at one end; this cup will receive the molten bronze when poured. The placement of this cup is critical. Several variables must be considered, including proper ventilation and shrinkage, as the molten bronze flows and distributes throughout the cavities of the mold. The outcome of the bronze pour depends largely upon the science of gating and spruing. The Shell (Investment Technique) The next step in the lost wax casting is creating the "investment". This consists of building a rock-hard ceramic shell in and around the hollow wax casting and sprue system. Though the materials are much more modern, this serves the same function as mud did 5,000 years ago. The ceramic shell, or investment technique, starts by dipping the gated wax into large vats of slurry and sand. This step is repeated several times, each time being completely dried prior to the next. The slurry coats go both inside and outside of the wax, allowing the sculpture to remain hollow. If a bronze sculpture were not cast hollow it would implode, shrink and distort as the molten bronze cools. The chemical makeup of the slurry is monitored constantly to ensure its consistency. Humidity and temperature of the slurry room must be controlled to allow for optimum drying and hardness of the slurry shell. At this stage, the wax is a positive, which must be melted away, in order to create a void, or negative, for the bronze to fill. So the "lost wax" portion of the foundry process is completed, when the invested shell is fired in a kiln, where the wax sculpture melts and evaporates, or is "lost" from the shell. Casting (The Bronze Pour) The shell is removed from the slurry room and placed in an autoclave or a burn-out oven, cup side down. A burn-out oven is simply a large flame heated oven; an autoclave is a large machine that heats up under steam pressure. Either method will allow the shells to cure (bake) and the wax to flow out. In this extreme heat, the shell has now become “ceramic”. Once the shells are de-waxed, they are cooled and inspected for cracking. Once again, they are heated up to approximately 1800 degrees and placed in the pouring pit. Molten bronze is heated in a separate crucible, under exacting conditions and monitored temperatures. The bronze is then poured into the hollow shells by a trained team and allowed to cool and solidify. Knockout and Welding Approximately one hour after the pour is finished, the piece is now cool enough to handle. The bronze casting is removed, or "devested" from the shell, using mallets, power chisels and hand tools. Skill and strength is required to reveal the casting without damaging the bronze sculpture. All the sprues are cut away, and the raw bronze is then glass beaded, water or sand-blasted to remove any remaining shell material from the intricate details of the casting. If the original was sectioned into multiple pieces, it would now be carefully fitted and welded back together. A visual inspection is done to check for any casting inclusions. Mounting studs are also added to hold the finished base. If there are any surface defects, these would also be repaired at this time. Metal Chasing The sculpture is then chased by trained craftsmen to remove any sign of welding and to prepare the bronze for the patina or coloring process. Several different sanding, grinding and hand detail tools must be used to duplicate the finish of the original sculpture without disturbing the adjacent texture. The finished raw bronze is then sand-blasted to clean the casting. This is again where the sculptor enters into the process for what is called the final 2%. The final 2% means that the finished bronzes are inspected by the artist to make sure the design and surface is accurate to the original. Any potential unseen flaws are corrected at this stage and the edition number is ground or stamped into the bronze. Patination The patina is the finished color. Depending on the artist's requirements, they may use a variety of different chemicals applied under heat, from 200 to 400 degrees, which react on the bronze to achieve a certain look or effect. The knowledgeable and talented patina artists offer a wide variety of techniques and colors to achieve what the sculptor desires. After the patina is applied and approved by the sculptor they will seal the sculpture with a wax or lacquer coat to protect the finish. Mounting Depending on the artist's design requirements, the completed bronze sculpture is now mounted on a custom base or pedestal. Bases are typically various woods or stone or the combination of the two. Felt protectors are then added to the bottom of the base. The completed bronze is now ready to be enjoyed for many generations to come! http://www.artbyknight.com