RAJALAKSHMI INSTITUTE OF TECHNOLOGY Kuthambakkam

advertisement

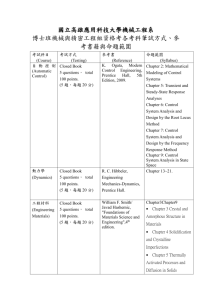

RAJALAKSHMI INSTITUTE OF TECHNOLOGY Kuthambakkam, Chennai-602107 LESSON PLAN Faculty Name : S.Janakiraman Subject Name : Unconventional machining process Code : ME 2026 Year : III Semester : VI Degree & Branch : B.E. – Mechanical Engineering Objective: To learn about various unconventional machining processes, the various process parameters and their influence on performance and their applications Text Book(s): 1. Vijay.K. Jain “Advanced Machining Processes” Allied Publishers Pvt. Ltd., New Delhi, 2007 Reference Book(s): 1. Benedict. G.F. “Nontraditional Manufacturing Processes” Marcel Dekker Inc., New York (1987). 2. Pandey P.C. and Shan H.S. “Modern Machining Processes” Tata McGraw-Hill, New Delhi (2007). 3. Mc Geough, “Advanced Methods of Machining” Chapman and Hall, London (1998). 4. Paul De Garmo, J.T.Black, and Ronald.A.Kohser, “Material and Processes in Manufacturing” Prentice Hall of India Pvt. Ltd., New Delhi ,8th Edition,2001. S. No. Date Hours Hours required taken Unit Topic(s) Book Book No. UNIT I INTRODUCTION 1 1 I 2 2-3 I 3 4-5 I 4 6 I 5 7 I Introduction to unconventional machining processes, their needs and classification Brief introduction to the type of energy source employed in AJM, USM , WJM Brief introduction to the type of energy source employed in EDM, ECM, ECG Brief introduction to the type of energy source employed in EDM, ECM, ECG Brief introduction to the type of energy source employed in LBM, PAM,EBM R 1,2,3,4 R 1,2,3 R 1,2,3 R 1,2,3 R 1,3,4 Abrasive Jet Machining, Working Principle – equipment used Abrasive Jet Machining ,Process parameters R 3 R 3 Abrasive Jet Machining, MRR-Variation in techniques used, Applications Water Jet Machining, Working Principle – equipment used Water Jet Machining- Process parameters R 3 R 3 R 3 Water Jet Machining ,MRR-Variation in techniques used, Applications Ultrasonic Machining, Working Principle – equipment used Ultrasonic Machining ,Process parameters R 3 R 3 R 3 Ultrasonic Machining, MRR-Variation in techniques used, Applications Comparison of process capabilities and parametric analysis R 3 UNIT-II MECHANICAL ENERGY BASED PROCESS 6 8 II 7 9 II 8 10 II 9 11 II 10 12 II 11 13-15 II 12 21 II 13 22 II 14 23-24 II 15 25 II R UNIT III ELECETRICAL ENERGY BASED PROCESS Electric Discharge Machining (EDM)working Principle Electric Discharge Machining (EDM) equipments-Process Parameters MRR- electrode / Tool – Power Circuits R 1,2,4, R 1,2,4,5 R 1,2,4, R 1,2,4, III Characteristic of the Electric Discharge Machining process Dielectric, Flushing R 1,2,4,5 31 III Wire cut EDM working Principles R 1,2,4, 32 III Process Parameters, equipments R 1,2,4, 16 25 III 17 26-27 III 18 28 III 19 29 III 20 30 21 22 S. No. Date 23 Hours Hours required taken 33 Unit III Topic(s) Book Book Characteristic of Machining process, Applications. R No. 1,2,4, UNIT IV CHEMICAL AND ELECTROCHEMICAL BASED PROCESS 24 46-47 IV Chemical machining, working Principle T 1,2,4 25 48 IV Etchants, Maskant, T 2,3,4 26 48-50 IV T 1,4 27 51 IV Process Parameters – MRR- T 2,3 28 52-54 IV T 1,2,3 29 55 IV Principles of ECM, Electrolysis, Functions of Electrolyte and its importance ECM machine tool, equipments T 2,4,5 30 57 IV Electrical circuit, MRR T - 31 58 IV T 1,4 32 59 IV Process Parameters of ECM, parametric analysis Principles of ECG, ECG Machine Tool T 1,4 33 60 IV Equipments, Process Parameters T 1,4,5 34 61 IV Electrical circuit, MRR T 2,3,4 35 62 IV Process Parameters ,Process characteristics T 2,3,4 R 1,3,5 R 1,4,5 Techniques of applying maskants UNIT V THERMAL ENERGY BASED PROCESS 36 63 V 37 64 V Laser Beam machining ,LBM -working Principle Types of laser, Equipments 38 65 V Process Parameters ,Process characteristics R 1,2,4 39 66 V R 1,2 40 67 V plasma Arc machining (PAM) working Principle plasma Arc cutting system, Equipments R 1,3,4 41 68 V Process Parameters ,Process characteristics R 1,3,4 42 69 V R 1,4,5 43 70 V R 1,4,5 44 71 V Electron Beam Machining (EBM)- working Principle Electron Beam machining system, Equipments Process Parameters ,Process characteristics R 1,4 45 72 V Beam control techniques – Comparison of process capabilities, Applications. T Text Book / R Reference Book Signature of the Staff In-Charge R Total Hrs: 72 H.O.D/Mechanical 1,4