[12] Papadopoulos AM, State of the art in thermal insulation

advertisement

![[12] Papadopoulos AM, State of the art in thermal insulation](http://s3.studylib.net/store/data/008608681_1-5e21fdf9f4563171816b06070ef79a6d-768x994.png)

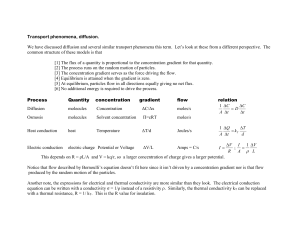

Heat transfer phenomena in fibrous insulating materials ANASTASIOS KARAMANOS, AGIS PAPADOPOULOS, DIMITRIOS ANASTASELLOS Laboratory of Heat Transfer and Environmental Engineering, Department of Mechanical Engineering Aristotle University Thessaloniki, GR-54124 Thessaloniki, GREECE Abstract: - Insulation has been and still remains on of the fundamental tools for achieving energy conservation both in the buildings’ and in the industrial sector. Whilst specific insulating materials are used for each application, according to the physical and operational requirements, there is a group of materials that is used in both cases, namely inorganic fibrous materials. The study of industrial insulating materials is a rather hard task, due to the complex phenomena which take place in the materials’ structure, because of the extreme conditions, in which the material is applied. In this paper are discussed some of these changes. The study presented focuses on stone wool, which is the most widely used, and in that sense the most representative inorganic fibrous material. Its performance is based on the air embodied between its fibers, which produce a low thermal conductivity factor. Under some operational conditions, however, like the increased presence of moisture, the thermal conductivity factor may change. The objective of this paper is to describe the theoretical approach and the resulting data on the assessment of the changes in stone wool’s thermal conductivity, under various operational conditions. In order to achieve that, a description of stone wool’s chemical composition and structure is given, followed by the physical and mathematical background necessary for determining the thermal conductivity factor. The results yielded in this way are compared to experimental and theoretical references available, in order to verify the validity of the adopted approach. Key-Words: - Fibrous insulating materials; Thermal conductivity; High temperature applications 1 Description of fibrous materials’ structure The common feature in all insulation materials is their low thermal conductivity factor λ, usually lower than 0.1 W/mK. This owes to the fact that a quantity of gas, usually air, is embodied in the material’s mass. Dry and firm air, when not moving and in small quantities, has the lowest thermal conductivity factor (approximately λ = 0,024 W/mK) over a wide range of temperatures. The most widely used categories of insulating materials are inorganic fibrous and organic foamy ones. In the former group, atmospheric air is “trapped” between the fibers, whilst in the latter the air is embodied in bubble form in the material’s mass. Considering materials applicable under high temperature conditions, like in industrial applications or when strict fire protection regulations apply, fibrous materials arise as the most interesting solutions. Organic foamy materials cannot be used in such cases, due to their very poor resistance to high temperatures and the increased hazard in case of fire X2. applied to, Therefore, a fibrous insulation material is studied in this paper. Stone wool is the most widely used, and hence most representative, fibrous inorganic materials, accounting for more than 35% of the European market (ibid). As some complex phenomena take place in the material’s structure when applied under varying temperature conditions, it is necessary to understand its physical and chemical structure and composition. It is therefore useful to describe the production process of stone wool. The main component of stone wool is an ore called amphibolite. Initially a mixture is prepared, consisting mainly of amphibolite and some additives, such as limestone (to the percentage of 6% per weight approximately) and various calcium oxides (to the percentage of 9% approximately). The contents of this primary mixture can vary, depending on the manufacturer and on the specific type of stone wool produced. Still, the foretold mixture can be considered as the one most widely used and hence a typical one. The primary mixture is led into a blast furnace, where it is heated to 1450 – 1520 oC. At this temperature, the ore is melting and obtains a lava form. Then it sheds in a cylindrical rotating tank, with a rotation speed of 700 rpm approximately. Therefore, the melted mixture is centrifuged and escapes from the tank’s surface through microscopic holes. As it escapes to the ambient temperature it cools down and becomes solid. During this process are created fibers, which compose formless quantities of stone wool. The next step is to make stone wool to take a compact form. Special resins are injected to the formless stone wool which is then compressed in order to obtain its usual shape of rectangular plates. Then, it is led in furnaces where at the temperature of 170 – 180 oC resins are combined with stone wool fibers and get solid. At the temperature of 250 oC resins harden giving to stone wool a form of relatively hard plate. It is important, that vaporization of the embodied water takes place, as this is produced from the resins’ injection. Finally, the plates of stone wool are available for use either as they are, or combined with other materials which form a coating, like aluminum leafs, particleboards etc. - Atmospheric air between fibers Additional substances used to increase the product’s resistance to biological impact. The participating percentage of each component varies Fig. 1: Stone wool production line A typical production process of stone wool is depicted in Fig. 1. The final features of stone wool can be synopsized as follows: - Fibers with circular crossection and very small diameter (usually d<15μm). The fibers can be vertically or parallel oriented to the plate’s surface. In the former case they feature improved mechanical strength and sound absorption, in the latter they feature better thermal insulation properties. In both cases some of the fibers are affined with each other and some are free. - Resins used for fibers’ cohesion depending on the application of the final product. So does the material’s density. This last parameter, which is determined by the ratio between the mass of fibers and the one of the embodied air, is the one that affects the thermal conductivity factor and therefore the heat transfer through the material. 2 Creating heat transfer model in a fibrous material The heat transfer model that fits better to the insulating materials’ case is the one of the homogeneous cylinder with infinite length. The fibers’ length can reach some millimeters contrary to fiber’s diameter, which reaches some micrometers. Therefore, the assumption that the fiber is a cylinder of infinite length can be used safely. There are four modes of heat transfer in a fibrous material: (1) Conduction through the solid medium, i.e. the fibers, (2) conduction through the gas medium, i.e. the air trapped between the fibers, (3) convection due to the air in the space between the fibers and (4) radiation interchange between fibers and air. Convection is caused by the air molecule’s movement. Taking into account the fact that, due to the very small dimensions of the cavities the air’s movement between the fibers is practically negligible, heat transfer of convection is minimal and can therefore be omitted from the calculations, without losing in accuracy. The participation of each mode of heat transfer in the total heat transfer for a wide range of temperatures is presented in Fig. 2. Such a wide range can easily be met in industrial applications. β: the extinction coefficient, T: the temperature, σ= 5.67∙10-8 W∙m-2∙ K-4 (Stefan – Boltzmann constant) The extinction coefficient is given by the equation: β = e∙ρ, where, ρ: the insulation material’s density e: the specific extinction coefficient 2.2 Heat transfer by means of gas conduction Having made the assumption that the air in the insulation material is stationary, the following equation can be used, which calculates the thermal conductivity factor by means of gas conduction: k*g kg 2 α 2γ 1 Φ 2Ψ Kn α γ Pr (2) where, Fig. 2: Participation of each heat transfer mechanism to the total [11]. The mathematical model which is presented was selected with two criteria: its appropriateness for the case of stone wool case and its simplicity which makes it usable with a reasonable computational effort. 2.1 kg*: the air’s thermal conductivity factor at atmospheric pressure, α: energy exchange between air’s and fibers’ molecules factor (Its value is between 0 and 1), γ: specific heat ratio, Pr: Prandtl number Kn: Knudsen number, which is calculated using the equation: Kn = λ/LC where, λ where, Kb= T: dg: P: Heat transfer by means of radiation In order to study the radiative heat flux a system of simultaneous differential and integral equations should be used. Several analytical methods were considered and the one presented in this paper is a fairly simple one, which still leads to satisfactiry results, approximating those produced by experiments. The equation that calculates the thermal conductivity factor by means of radiation is therefore: kR 16 σ 3 Τ 3β (1) where, kR : thermal conductivity factor through radiation, The middle free path of air’s molecules ΚΒ Τ 2 π d g2 P [m] (3) 1.3806∙10-23 [J/K], temperature [K], air’s collision diameter [m], pressure [Pa] The characteristic length LC π Df 4 f (4) where, Df: fibers’ diameter [m], f: the ratio of insulation material density to the fibers’ material density Φ, Ψ: parameters values are: Φ = 1, Ψ=0, when Kn < 0.01 Φ = 1, Ψ=1, when 0.01 < Kn < 10 Φ = 0, Ψ=1, when Kn > 10 2.3 2.5 Heat transfer by means of solid conduction (fibers) The most exact equation that calculates the thermal conductivity factor through fibers is: kS f 2 λ**Σ (5) where, λS**: fibers’ material thermal conductivity factor f: the ratio of insulation material density to the fiber’s material density 2.4 Equivalent thermal conductivity factor (Fibers and air thermal conductivity) The first step is to combine the air’s thermal conductivity factor with the fibers’ one. There are many methods that can be used in order to combine the thermal conductivity factors of a gas and a solid medium. In this paper the following equation is used to calculate the total thermal conductivity factor by means of conduction: k cond k s kg ks k ks f 1 1 z g 1 f k g k s (6) where, kg, ks: the thermal conductivity factors through gas and solid conduction respectively that calculated using Equations 2 and 3, z: a coefficient that takes the values: 1, when fibers are oriented vertical to the heat flux direction 2/3, when fibers are randomly oriented 5/6, when the 50% of fibers are oriented vertical to the heat flux direction and the other 50% is randomly oriented This method is preferred, because it takes into consideration the fibers’ orientation, using the z coefficient. Generally, the fibers’ orientation in an insulation material depends on the fibers’ material, the production method and the aimed final result. Using the production method of stone wool described in paragraph 1, the fibers take random orientation. Therefore, the value z=2/3 is being used. Total equivalent thermal conductivity factor Finally, thermal conductivity factors by means of radiation and conduction are combined, in order to calculate the total thermal conductivity factor of the insulating material by using the equation: k total k cond k r k conv (7) where, kcond, kr: The conductivity factors through conduction and radiation respectively, as they calculated in Equations 4 and 2. kconv: Thermal conductivity factor for heat transfer with convection, which is practically null and it’s not been taken in notice in calculations. 3 Stone wool and its behavior under varying temperatures The advantage of the inorganic fibrous materials in generally, but more than so of stone wool, lies in the fact that it can be used in very high temperatures, of up to 1000 oC. Furthermore, fibrous materials have high fire resistance and they can be therefore used in any other sort of applications, from particular buildings constructions to shipbuilding. Still, their insulating behavior does change with varying temperature conditions, a fact that should not be neglected when designing and dimensioning insulation solutions. The determination of the change of the thermal conductivity factor, depending on the change of some application conditions is discussed in the following paragraphs. 3.1 Temperature increase When temperature increases, changes in the thermal conductivity take place for each heat transfer mechanism discussed earlier. Within the frame of this research a calculation spreadsheet was created using the heat transfer model described by equations (1) to (7). Temperature is given as input and the thermal conductivity factor for each heat transfer mechanism as well as the total one are extracted. The temperatures of 25, 50, 75, 100, 250, 500 and 1000oC were used as input. The results depicted in Fig. 3 indicate the variations arising for each different heat transfer mode. In Fig. 4 is depicted a similar diagram produced by another research, in order to allow comparisons with respect to the described model’s accuracy. It has to be noticed that fibers split was not taken into consideration. This effect begins to take place for temperatures over 200oC, where the binder resins decompose. In practice however, this phenomenon becomes important for temperatures over 500oC, k(T) = = 3.6-0.49·10-2 T+0.61·10-5 T2-2.58·10-9 T3 (8) where T is given in K. b) As density of fibers the mean value of common ceramic fibers was used and it is ρF = 2700 kg/m3 and for the fibers’ diameter, an average value of DF = 15·10-6 m was used. c) The value of extinction coefficient is e= 60 m2/kg, as it used in a relative study for fibrous material [13] d) The density of stone wool varies according to its type and the intended application, as it can be seen in Table 1. For this study a heavy type was considered, like the ones used in industrial applications. The value used is ρ= 250 kg/m3 EN 12667 EN 826 DIN 4102 Vapor penetrability factor Maximum operation temperature [oC] Tensile strenght at 10% compression [kPa] Thermal conductivity [W/(mK}] Application - Density [kg/m3] - EN 52615 Buildings: Floors Industrial applications 175 200 0.0315 9,18 750 1 0.036 17.1 750 1 0.04 19.74 1000 1 e) The energy exchange between the air’s and the fibers’ molecules factor α takes values between 0 and 1. In this paper unity was used. f) Values for specific heat ratio γ where taken from [15] and linear interposition method used where the value was not available. The results of the calculations are summarized in Table 2 and presented in Fig.3 and Fig. 4. Table 2: Results of the calculations of the model described. Thermal conductivity (W/mK) Temp (oC) kR kG kS kTOT 25 0,0011 0,0262 0,0224 0,0269 50 0,0014 0,0276 0,0220 0,0284 75 0,0017 0,0290 0,0216 0,0300 100 0,0021 0,0304 0,0213 0,0316 250 0,0058 0,0389 0,0200 0,0426 500 0,0186 0,0530 0,0194 0,0677 1000 0,0832 0,0813 0,0165 0,1561 0,18 0,16 0,14 0,12 0,10 0,08 0,06 0,04 0,02 0,00 0 50 Buildings: Walls Test method Feature Table 1: Main features and application for stone wool of various densities. 100 Thermal conductivity [W/(mK)] because only then the material’s density begins to change dramatically. The following assumptions where made for the calculations: a) The fibers’ thermo-physical properties are the same with the ones of amphibolite, as the latter is the fibers’ raw material. Therefore, the thermal conductivity factor of the fibers can be calculated using the Cemark and Raybach approximation, 1982, for rocks: [16] 0.0327 2,34 750 1 250 500 750 Temperature (oC) Radiation Solid Conduction 1000 Gas Conduction TOTAL Fig. 3: Results of the calculations of the model described . Participation of each heat transfer mechanism to total 3.2 100% 90% 80% 70% 60% 50% 40% 30% 20% 10% 0% 25 50 75 100 250 500 1000 Temperature oC Radiation Gas conduction Solid conduction Fig. 4: Participation of each heat transfer mechanism to the total. 3.3 Fig. 5: Thermal conductivity versus temperature for fibrous insulation material. Experimental (1,2 and 3) and calculation (4) results by related study [9]. As it can be observed, for low temperature, the thermal conductivity has fairly low values. That happens because heat transfer through convection has not been considered in the calculations. The real thermal conduction should therefore be 5 – 10% higher that the calculated one. Still, the calculated data are quite similar to the experimental ones, which are presented in Fig 5. Finally, the participation of each heat transfer mechanism to the total is similar to the data presented in Fig. 3. As it was expected, the contribution of radiation increases with the temperature, while the one of conduction through fibers decreases. Other phenomena that affect in the thermal conductivity factor are discussed in the following paragraphs. Water absorption Stone wool is a porous material, with open air spaces in its maze. That makes it a quite hydrophilic material. When vapor is diffused in the materials’ maze, it replaces the air quantities. But, vapor and atmospheric air have similar thermal conductivity factors (i.e. at 20 o C, kair = 0.024 W/(m2K) and kvapor = 0.020 W/(m2K)) as well as some other thermo physical properties. Therefore, the replacement of air, with vapor causes minimal change in the total thermal conductivity factor. On the other hand, water’s thermal conductivity is significantly greater than air’s (at 20oC, kwater = 0.604 W/(m2K)). Therefore, the diffusion of water in the material’s maze causes a significant increase of the stone wool’s thermal conductivity factor. This highlights the danger of vapor diffusing into the insulating material, as in case of condensation it will lead to a significant failure of the insulation. Relative researches concluded that 1% moisture content by volume can increase k by up to 107%. [17] In that sense, the use of vapor barriers has to be considered, with respect to the specific application and the probability of vapor condensation occurring. This problem is also associated with the decomposition of fibers. Fibers decomposition Decomposition of fibers can be caused under conditions of high temperature and high moisture. In high temperatures, binder resins are polymerized and stop keeping fibers connected. For increased moisture conditions, two processes of degradation where noted: Chemical degradation, where binder resins are separated from the fibers and chemical hydration, where the fibers’ surface is affected and fiber lose its stress resistance. Finally, the previous phenomena lead to the creation of segmented fibers, on a micro-scale, and to the decrease of the material’s density on a macro-scale, because fibers get detached from the material’s main body. As a matter of fact, fibers’ degradation starts to take place at the point, where the increase of k becomes non-linear in terms of a k-T or k-RH(%) function. This effect, which is not rare in the case of industrial insulation (e.g. when insulated steam pipes are lead through closed and fairly humid areas) leads to a significant increase in the material’s thermal conductivity factor. 4 Conclusions Stone wool is a powerful insulation tool for the designer and the constructor. It is one of the few insulating materials that can be used in a very wide range of temperatures. Also, it can be used in many different applications, due to the flexibility and adaptability of form and shape. However, it is hydrophilic and water absorption increases its thermal conductivity factor dramatically. That would cause damage to the insulated application. Using vapor barriers, like protective membranes, can solve this problem. High temperatures cause an increase of the thermal conductivity factor. This is not straightly tortuous, but it should be taken into consideration in primary calculations of each individual application. Furthermore, when temperatures exceed a certain level, the fibers are separated; the insulating material is damaged and should therefore be replaced. In the case of such high temperature applications, insulation should be replaced periodically. The methodology presented in this paper is a simple, but still reliable, tool which enables the assessment of the materials performance under realistic conditions of operation, and therefore also the prediction of possible failures. [8] References: Papers [1] Kamran Daryabeigi, AIAA 99-1044 / Analysis and Testing of High Temperature Fibrous Insulation for Reusable Launch Vechicles, 37th AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, January 11-13, 1999 [2] Kamran Daryabeigi, AIAA 2002-3332 / Heat Transfer in High – Temperature Fibrous Insulation, 8th AIAA/ASME Joint Thermophysics and Heat Transfer Conferencet, St. Louis, MO, June 24-26, 2002 [3] Walter W. Yuen, COMBINED CONDUCTIVE/RADIATIVE HEAT TRANSFER IN HIGH POROSITY FIBROUS INSULATION MATERIALS: THEORY AND EXPERIMENT, The 6th ASME-JSME Thermal Engineering Joint Conference, March 16-20, 2003 [4] A. Milandri, F. Asllanj, G. Jeandel, J.R. Roche, Heat transfer by radiation and conduction in fibrous media without axial symmetry, Journal of Quantitative Spectroscopy & Radiative Transfer,74 (2002), p. 585-603 [5] H.J. Rice, P. Göransson, A dynamical model of light fibrous materials, International Journal of Mechanical Sciences, 41 (1999), p. 561-579 [6] T. Ohmura, M. Tsuboi and T. Tomimura, Estimation of the Mean Thermal Conductivity of Anisotropic Materials, International Journal of Thermophsysics, Vol. 23, No. 3, May 2002 [7] L. E. Evseeva and S. A Tanaeva, INFLUENCE OF IMPREGNATION ON THE THERMAL PROPERTIES OF HEAT- INSULATING FIBROUS MATERIALS, Journal of Engineering Physics and Thermophysics, Vol. 77, No. 2, 2004 [11] [9] [10] [12] [13] Jintu Fan, Xiaoyin Cheng, Xinhuo Wen, Weiwei Sun, An improved model of heat and moisture transfer with phase change and mobile condensates in fibrous insulation and comparison with experimental results, International Journal of Heat and Mass Transfer, 47 (2004), p. 2343-2352 V. G. Petrov-Denisov, V. S. Zholudov and V. V. Gur’ev, A METHOD FOR ESTIMATING HEAT-SHIELDING PROPERTIES OF MINERAL WOOL INSULATION BASED ON SILICATE FIBROUS MATERIALS, Glass and Ceramics, Vol. 57, Nos. 9-10, 2000 (Translated from Seklo i Keramika, No. 9, pp. 24-31, September, 2000 Derek D. Hass, B. Durga Prasad, David E. Glass and Karl E. Wiedemann, Reflective Coating on Fibrous Insulation for Reduced Heat Transfer, NASA CR-201733, pp. 24, August 1997 Markus Spinnler, Edgar R. F. Winter, Raymond Viskanta, Thomas Sattelmayer, Theoretical Studies of High Temperature Multilayer Thermal Insulations Using Radiation Scaling, Proceedings of Eurotherm 73 on Computational Thermal Radiation in Participating Media, Mons, Belgium, 15-17 April 2003 Papadopoulos A.M., State of the art in thermal insulation materials and aims for future developments, Energy and Buildings, in press J. Hetfleish, U, Heinermanm, J. Fricke, Experience with Vacuum Insulation Panels, Proceedings of Nordic District Heating Seminar, Aarhus, DK, 2 May, 2001 Books [14] S. I. Karekos, Heat transfer – Insulation (In Greek), Publications of Technical Chamber of Greece, 2001 World Wide Web’s sites [15] http://www.engineeringtoolbox.com/ 22_602.html (Air’s Specific Heat Ratio Values in S. I. Units and atmospheric pressure) [16] http://www.unileoben.ac.at/ ~geophwww /neu/data/chapter8thermal.pdf (Part of study published, with title :“Chapter 8: Thermal Properties of Rocks”) [17] www.insulation.kingspan.com/ newdiv/issues01.htm (Kingspan insulation – issues to consider)