Material Properties - Advanced-Introduction

advertisement

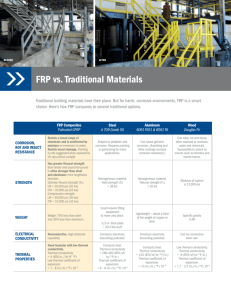

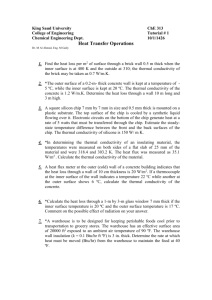

Material Properties - Advanced - Introduction A material's property is an intensive, often quantitative property of a material, usually with a unit that may be used as a metric of value to compare the benefits of one material versus another to aid in materials selection. A material property may be a constant or may be a function of one or more independent variables, such as temperature. Material's properties often vary to some degree according to the direction in the material in which they are measured; a condition referred to as anisotropy. Materials properties that relate two different physical phenomena often behave linearly (or approximately so) in a given operating range, and may then be modeled as a constant for that range. This linearization can significantly simplify the differential constitutive equations that the property describes. Some material's properties are used in relevant equations to determine the attributes of a system a priori. For example, if a material of a known specific heat gains or loses a known amount of heat, the temperature change of that material can be determined. Materials properties may be determined by standardized test methods. Many such test methods have been documented by their respective user communities and published through ASTM International. Some material properties are noted below Acoustical properties: Acoustical absorption, Speed of sound, … Atomic properties: Atomic mass, Atomic number (pure elements only), Atomic weight (individual isotopes or specific mixtures of isotopes of a given element), … Chemical properties: Corrosion resistance, Hygroscopy, pH, Reactivity, Specific internal surface area, Surface energy, Surface tension, … Electrical properties: Conductivity, Dielectric constant, Dielectric strength, Electrical conductivity, Permeability, Permittivity, Piezoelectric constants, Seebeck coefficient, … Environmental properties: Embodied energy, Embodied water, RoHS compliance,… Magnetic properties: Curie Point, Diamagnetism, Hysteresis, Permeability ,… Manufacturing properties: Castability, Extruding temperature and pressure, Hardness, Machinability rating, Machining speeds and feeds Mechanical properties: Compressive strength, Density, Ductility, Fatigue limit, Flexural modulus, Flexural strength, Fracture toughness, Hardness, Plasticity, Poisson's ratio, Shear modulus, Shear strain, Shear strength, Softness, Specific modulus, Specific weight, Tensile strength, Yield strength, Young's modulus, … Optical properties: Absorptivity, Colour, Luminosity, Photosensitivity, Reflectivity, Refractive index, Scattering, Transmittance, … Radiological properties: Neutron cross-section, Specific activity, Sensorial properties: Brightness, Smell, Softness, Warmth, Form Thermal properties: Autoignition temperature, Binary phase diagram, Boiling point, Coefficient of thermal expansion, Critical temperature, Curie point, Emissivity, Eutectic point, Flammability, Flash point, Glass transition temperature, Heat of fusion, Heat of vaporization, Inversion temperature, Melting point, Phase diagram, Pyrophoricity, Specific heat, Thermal conductivity, Thermal diffusivity, Thermal expansion, Seebeck coefficient, Triple point, Vapor Pressure, Vicat softening point Atomic, Chemical, Material, Manufacturing and Thermal properties are the main focus of this course. A case study is presented for the measurement of phase type and residual stress in a laser treated biomedical alloy.