Christopher D - Maintenance Engineer, Reliability Engineer, Project

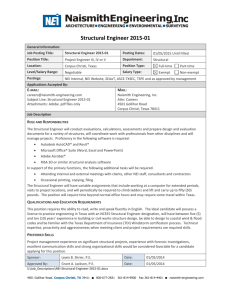

advertisement

Christopher D. Endrai Friendswood, Texas Cell: (713) 703-1420 Email: cendrai@swbell.net SUMMARY/ KEYWORDS Maintenance Engineer, Reliability Engineer, Project Engineer, strong in ANSI & API rotating equipment, petrochemical and refinery-like services. Propylene oxide, ethyl benzene, styrene, polyethylene, polypropylene, surfactants, barrier resins. Pumps, compressors, steam turbines, extruders. Developed grass roots vibration monitoring programs, managed turnarounds, improved pump MTBF 20%, experienced in root cause failure analysis and FMEA, supervisory experience includes filling in for managers and mentoring less experienced engineers. Intermediate level SAP user. Project scoping and management up to $5MM. SELECTED PERSONAL ACHIEVEMENTS Reduced out-of-service pumps by 60%, rework by 80%, increased Mean Time Between Failure 20%, reduced lost production opportunity (due to rotating equipment failures) by $1,800,000 per year. Initiated and led Failure Modes & Effects Analysis on an entire production unit that was experiencing unusually low on-stream time of 55% for 2-3 months. My team’s analysis was completed in 10 days; our 155 recommendations restored on-stream time to 94% within 2 mos. Planned and directed a month long turnaround, completed 6 days early despite a 25% change in scope due to discovery work. I also monitored daily progress of the critical path refurbishment of a copper distillation tower at a 3rd party shop and wrote a 30 page technical report on this. Developed a grass roots vibration monitoring program, performed analysis. Data driven recommendations on a 700 hp and a 1000 hp motor avoided $2,000,000 in lost production. PROFESSIONAL EXPERIENCE EVONIK ROHMAX USA November 2009 – present Senior Maintenance & Reliability Engineer, Deer Park, Texas Support day to day to maintenance, maintain mechanical integrity programs, develop condition monitoring program, develop spare parts catalog in SAP, develop training and procedures for best maintenance practices, conduct 3rd party repair shop evaluations Specified and purchased laser shaft alignment tool and handheld vibration analyzer. Implemented grass roots condition monitoring program including vibration monitoring and lube oil sampling/analysis. I developed the vibration database and routes, collected data, and wrote an ISO departmental procedure on how to perform those tasks. Implemented best practices for lube oil handling and storage, identified incorrect lubricant in several pieces of rotating equipment, specified correct product. Developed standard for lubrication fittings on rotating equipment to prevent or manage moisture intrusion. Developed Top 10 bad actor list from pareto analysis of SAP data. Developed SAP material stock request form, improved material stock & issue workflow Page 1 of 4 Managed tank & RV inspection program, including implementing a risk based strategy for prioritizing overdue inspections. I prepared a technical proposal to obtain funding for repairs to a major EHS critical tank. Conducted investigation of low reliability on reactor jacket cooling system; identified and corrected or made recommendations on several faulty mechanical components. I did this as a member of a focused improvement team that included training operators on the how the system should operate. Developing and executing plan for repair of failed Production-critical triplex plunger pump, conducting root cause investigation. Prepared recommendations for overhaul of remaining pumps to ensure long term reliability. Prepared job description for and supervised mechanical engineer co-op student. LYONDELLBASELL Oct 2005 – August 2009 Principal Machinery Engineer, Channelview, Texas Oct 2008 to August 2009 Responsible for performing root cause failure analysis, recommending improvements, and providing technical support for repairs of 700 pieces of machinery for an MTBE unit (32K barrels/day), Butanediol unit (134MM lbs/year), Polyols unit (565MM lb/yr) and Utilities unit (1.8 MM lbs/hr steam). Lead Pump Improvement Team, identified $502K/yr in improvement opportunities. Eliminated $400K in seal failures on production critical pump by correcting mechanical run outs in the pump, modifying the seal face profiles, eliminating contaminants in the seal support system, and addressing quality control problems at the seal vendor’s repair facility. Led Utilities PM Optimization effort on rotating equipment and boiler instrumentation. Consolidated 700 separate PM tasks into one event, improving manpower utilization by 50%. This effort also ensured that all safety critical PM’s (turbine overspeed tests) on forced draft fans were completed without requiring additional boiler outages. Developed overhaul procedure for diaphragm metering pump. This solved a 5 year old reliability problem on an environmentally critical pump, MTBF improved from 1 week to 1 year running. Senior Mechanical Maintenance Engineer, Channelview, Texas Oct 2005 – Oct 2008 Responsible for support of rotating/stationary equipment repairs, including 1,400 pieces of rotating equipment in two 600MM lb/yr propylene oxide/styrene monomer plants. Responsible for mentoring co-op and new graduate engineers. Performed root cause investigation of failure of 5,100 hp steam turbine. This included overseeing a 3rd party fluid dynamics analysis and finite element analysis of the turbine nozzles and blades. This failure cost the company $4MM. Presented the findings to the Senior Vice President of Lyondell. Reduced out-of-service pumps by 60%, rework by 80%, increased MTBF 20% by leading spare parts reviews, conducting root cause analyses, and promoting best maintenance practices for pump repairs. Implemented steam trap maintenance program including workflow procedures, saving $1MM/yr in steam losses and turbine damage. Eliminated repeat seal failures of 600 hp pump in 430 degree benzene service. This had resulted in $300K in maintenance costs, 4 reportable environmental incidents, and 2 emergency responses. Developed Maintenance Engineer Toolbox – this is a website developed for the LyondellBasell intranet to help maintenance engineers identify technical tools and resources to help them carry out their daily duties. Page 2 of 4 BASELL POLYOLEFINS July 2001 – Oct 2005 Senior Mechanical Reliability Engineer, Bayport, Texas Responsible for support of rotating/stationary equipment repairs in 170Klbs/hr polypropylene manufacturing facility. Chaired Predictive Maintenance Committee, back-up to Maintenance Manager. Led Failure Modes & Effects Analysis on an entire production unit. This unit was experiencing unusually low on-stream time of 50-55% for 2-3 months. Our emergency analysis was completed in 10 days and the team’s 155 findings and recommendations restored on-stream time to 94% within 1-2 months. Led Root Cause Analysis of catalyst metering cylinder failures. Changes to the piston seal design and a system flushing procedure increased MTBF from 10 days to 1 year. Led Root Cause Failure Analysis of Aerzen screw compressor failures on pellet conveyor system. Previously there had been 155 trips of the conveying system over 5 years and several shutdowns of a 100K lbs/hr extruder. By identifying several malfunctioning control valves and limit switches, we eliminated this and $400K in repair expense and rental equipment costs. Analysis of Sundyne and Sunflo pump failures reduced maintenance costs and downtime by 75%. Problems included gearbox foaming, seal leaks, shaft failures, and chronic vibration. Reduced trips of Ingersoll Rand Centac instrument air compressors, from once/week to once/year. Identified intercooler fouling and condensate trap failures as the source of impeller damage, compressor surge, and shutdowns from high temperature. HUNTSMAN PETROCHEMICAL April 2000 – July 2001 Senior Mechanical Engineer, Dayton, Texas Responsible for support of maintenance, back-up to Maintenance Manager. Also responsible for small capital project management and development and management of vibration monitoring programs. Expanded the vibration monitoring program by 300% and gained approval to obtain a dedicated hand held analyzer for the site. Designed and installed a $200K hazardous powdered additive handling project. This eliminated exposure of employees to hazardous phosphorous pentaoxide dust. Reduced spare parts inventory costs on reactor agitator seals by 90% and downtime to repair by 75% by standardizing components. EVAL COMPANY OF AMERICA April 1994 – April 2000 Maintenance Engineer, Pasadena, Texas Responsible for support of mechanical maintenance of 3 barrier resins units, small project management. This was a sold-out specialty resin unit, of which we were 1 of 2 manufacturers in the world. We were able to keep the plant running at 99% reliability & deliver product when our competitor couldn't. Responsible for turnaround planning, scheduling, and execution. Planned and directed 2 major turnarounds, injury free. The largest turnaround, 1 month in duration, included tie-ins for a new production line that we were building. By building contingencies into the plan, it was completed 6 days early despite a 25% change in scope due to discovery work. During this turnaround, I monitored daily progress at a 3rd party shop of refurbishment of a 135 ft copper distillation tower and wrote a 30 page summary report of this work. Page 3 of 4 I was responsible for implementation of an in-line optical pellet sorter to guarantee defect-free product to critical customers. I originated the idea, researched the available technologies, conducted controlled tests with a pilot unit to prove the technology and fine tune the specifications for the equipment, scoped/estimated/obtained funding for the project, supervised installation, and commissioned the unit. This had previously required 12 people to manually sort a fraction of the product; now we were able to automatically inspect 100% and guarantee quality for all of it. Developed grass roots vibration monitoring program and performed routine analysis. Data driven recommendations on a 700 hp and 1000 hp motor avoided $2MM in lost production. Supervised rotating equipment check-out/commission in new unit, established spare parts inventory for 300 pieces of equipment. Developed grass roots maintenance and inspection policies & procedures for vessels, tanks, piping. Filled in for Maintenance Manager for 3 months while he was on an overseas assignment. We remained within budget and equipment on-stream time remained at 99.7%. Hands on support, including literally assisting craftsmen with tools on emergency overhauls of diaphragm metering pumps, gear product pumps, and fluid bed dryer fans. QUANTUM CHEMICAL May 1991 to April 1994 Project Engineer, Deer Park, Texas Responsible for scope/estimate development, equipment specification, construction of projects up to $5MM Managed a $300K cyanide wastewater discharge reduction project. We were under an enforcement deadline from the EPA and faced $6MM in fines. Worked with a chemist to develop a unique process design, obtained expedited approval of funds from the divisional vice president, and worked 90 hrs/week to complete this project successfully. Managed a $1MM air emissions reduction project in a slurry HDPE unit. We were also under an enforcement design from the EPA. A similar plant had installed a $7MM incinerator to destroy this waste. Came up with a successful alternative solution for $1MM. The preliminary scope/estimate inherited was off by over 100%. Detailed scope documents and control estimate, which eventually became a department standard, resulted in a project that was completed within 0.5% of budget. EDUCATION B.S. Mechanical Engineering, May 1991 Purdue University, W. Lafayette, IN CERTIFICATIONS/SPECIAL TRAINING: Vibration Institute, Level 2 analyst, 2006 International Council for Machinery Lubrication, Level 1 analyst, 2006 Intl Gas Turbine Institute Workshop – Basic Gas Turbine Metallurgy & Repair Technology, Sept 2009 John Crane Sealing Technology 3 Day Course - May 2010 Page 4 of 4