Correlation between biogenic amines content and the bacterial load

advertisement

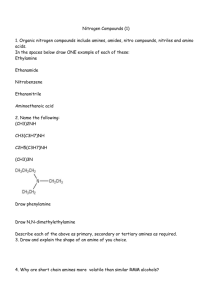

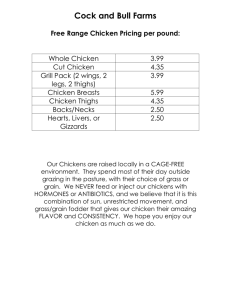

Correlation between biogenic amines content and the bacterial load of some ready to eat chicken products Gehan, S. A. Afifi and Reham, A. Amin Food Control Department, Fac. Vet. Med., Benha University Abstract Thirty random samples of shiesh tawook, chicken shawerma and chicken panee (10 of each) were collected from different restaurants in Kaluobyia and Gharbia governorates to be analyzed for biogenic amines by using HPLC. The obtained results revealed that the average concentrations of histamine, tyramine, putrescine and tryptamine (mg / 100g) were 12.39 ± 1.75, 15.32 ± 2.19, 8.25 ± 1.12 and 5.56 ± 0.77 for shiesh tawook, 9.61 ± 1.44, 10.73 ± 1.40, 5.69 ± 0.83 and 4.97 ± 0.63 for shawerma and 7.23 ± 1.01, 9.94 ± 1.16, 4.54 ± 0.65 and 4.70 ± 0.68 for chicken panee, respectively. In general, the levels of such amines were significantly higher (p < 0.05) in sheish tawook as compared with shawerma and chicken panee. According to the permissible limits recommended by EOS (1996), 20%, 20% and 10% of the examined samples of sheish tawook, shawerma and chicken panee were unaccepted as a result of their histamine contents. While, all the examined samples of such products were accepted based on their tryptamine contents. Only 30% and 10% of the examined sheish tawook samples exceeded the safe permissible limits of histamine and putrescine (20 mg %), respectively. In this respect, the acceptability of such examined samples for biogenic amines according to EOS (1996) and FDA (2001) was recorded. Also, the correlation between the concentration of biogenic amines and the bacterial load of such examined samples was considered. Finally, factors affecting the production, public health hazards and the recommendations for controlling the production of biogenic amines were discussed. Introduction The production and consumption of ready to eat chicken products have increased significantly throughout the world during the last decade, due to their desirable sensory characteristics, easiness and variety of preparation methods (Balamatsia et al., 2006). Susceptibility of ready to eat chicken products to microbial spoilage is an economic burden which in some cases may also present a health hazard, since poultry meat may harbor pathogenic microorganisms (Geornaras et al., 1995). Chicken meat is very susceptible to chemical, physical changes and biological agents. Alternative methods involving chemical changes resulting from microbial activity have been studied intensively (Balamatsia et al., 2006) to identify the spoilage of ready to eat chicken products before its detection by sensory analysis. Several chemical indicators have been proposed to assess the chicken products quality including volatile bases, nucleotides breakdown products, volatile acidity and biogenic amines (Veciana – Nogués et al., 1997 and Byun et al., 2003). In foodstuffs, biogenic amines occur either as physiological constituents (Paleologos et al., 2003), as they are a natural part of cell structure, or as a consequence of enzymatic amino acid decarboxylation due to microbial enzymes (Baston et al., 2008) In general, the most important biogenic amines in ready to eat chicken products are histamine, tyramine, tryptamine and putrescine which are formed by the enzymatic decarboxylation of histidine, tyrosine, trytophane and ornithine, respectively (Kim et al., 2001 and Ruiz – Capillas and Jimenéz – Colmenero, 2004). 1 The production of biogenic amines in ready to eat chicken products has been attributed to several bacterial species as Pseudomonas, Enterobacteriaceae, Enterococci, Bacillus, Clostridium, Hafnia, Klebsiella, Proteus, Lactobacillus, Achromobacter, Salmonella, Shigella, Micrococcus, Staphylococci and Morganella morganii (Durlu – Özkaya et al., 1999 and Lonvaud – Funel, 2001). Biogenic accumulation in ready to eat chicken products requires the availability of precursors (i.e. amino acids), the presence of microorganisms with amino acid decarboxylases, as well as favorable environmental conditions for their growth and decarboxylating activity (Roig, 2002 and Allen et al., 2004) as high temperature, high pH and low salt content (Komprda et al., 2001 and Bover – Cid et al., 2006). In some cases, biogenic amines may reach concentrations in foods, which are dangerous for consumers with enhanced sensitivity to biogenic amines determined by the inhibition of the action of aminooxidases, the enzymes involved in the detoxification of these substances (Suzzi and Gardini, 2003). Very little information is available on the levels of biogenic amines in ready to eat chicken products and their correlation to the bacterial load of such products. Therefore, the objectives of the present study were to assess the concentrations of the common biogenic amines in some ready to eat chicken products using HPLC, to correlate the levels of biogenic amines of such products with their bacterial load and to investigate the possible role of biogenic amines as chemical indictors of ready to eat chicken products spoilage. Material and Methods Collection of samples: A grand total of thirty random samples of ready to eat chicken products represented by shiesh tawook, chicken shawerma and chicken panee (10 of each) were collected from different restaurants in Kaluobyia and Gharbia governorates. The samples were transferred to the laboratory under complete aseptic conditions without undue delay to be examined as follows: 1. Determination of APC (ICMSF, 1996) 2. Estimation of biogenic amines: The estimation of biogenic amines as histamine, tyramine, putrescine and tryptamine was recorded by using HPLC according to Moret and Conte (1996) as follows: 2.1. Amine extraction: Accurately, 25 gm of the examined sample were homogenized with 125 ml of 5% trichloroacetic acid (TCA) for 3 minutes using a blender, and then filtrated using filter paper Whatmann No. (1). Moreover, 10 ml of the extract were transferred into a suitable culture test tube with 4 gm NaCl and 1 ml of 50% NaOH, then shacked and extracted 3 times by 5 ml n – butanol chloroform (1: 1 V / V), stoppered and shacked vigorously for 2 min. followed by centrifugation for 5 min. at 3000 rpm and the upper layer was transferred to 50 ml separating funnel using disposable pasture pipette. To combine organic extracts (upper layer), 15 ml of n – heptane were added and extracted 3 times with one ml portions of 0.2 N HCl, then N HCl layer was collected in a glass stopper tube. Solution was evaporated just to dryness using water bath at 95οC with air currents. 2.2. Derivatives formation (Dansyl amines): 200 ml of each stock standard solution (or sample extract) were transferred to a culture tube and dried under vacuum. About 0.5 ml of saturated NaHCO3 solution was 2 added to the residue of the sample extract (or the standard). The tube stoppered and carefully mixed to prevent loss due to spattering. Carefully, one ml dansyl chloride solution was added and mixed thoroughly using Vortex mixer. The mixture was kept in a water bath at 70οC for 10 min. then, the extraction of dansylated biogenic amines was carried out using 3 times of 5 ml portions of diethyl ether, and the ether layers were collected in a culture tube using disposable pasture pipette. The combined ether extracts were carefully evaporated at 35οC in dry film and dissolved in one ml methanol, then 10 micro litres injected in HPLC. 2.3. Interpretation of HPLC (Moret and Conte, 1996): The most common technique for amine analysis is HPLC using derivatization before detection. Accordingly, 5 – dimethylamine – 1 – naphalene sulphonyl chloride was used as derivatization reagent which characterized by the reaction with both primary and secondary amine groups. Furthermore, 10, 20, 30, 40 and 50 microlitre of dansyl amine standard as well as 10 micro litres of each dansylated sample extract was used. However, the chromatogram was examined under long wave of ultraviolet (254 nm) to establish weather or not the dansyl amines of interest are present in the examined sample. Finally, the concentration of each biogenic amine in the samples was recorded as mg/100 gm according to the following formula: Amine concentration (mg/100 gm) = CV / W Where, C: concentration of amine standard (mg / gm) V: final dilution of sample extract (ml) W: weight of the sample in the final extract (g) Statistical Analysis: The obtained results were statistically evaluated by using analysis of variance (ANOVA) test according to Feldman et al. (2003). Results Table (1): Correlation between APC and the concentration of biogenic amines in the examined samples of ready to eat chicken products (n=10) Biogenic amines APC Correlation Samples (mg/100gm) (cfu/gm) coefficient (r2) Min. Max. Mean ± S.E. Min. Max. Mean ± S.E. Shiesh tawook Shawerma Chicken panee 2.5 28.3 9.86±1.35 1.9x104 1.3 1.1 25.7 18.3 7.50±1.08 6.61±0.79 1.4x104 9.8x103 2.7x107 7.0x106 3.8x106 5.23x106±1.17x106 +0.52* 1.81x106±0.33x106 4.69x105±1.02x105 0.71** 0.59* * Significant correlation ** High significant correlation Table (2): Concentration of histamine (mg/100gm) in the examined samples of ready to eat chicken products and their acceptability according to EOS (1996) and FDA (2001) (n=10) Samples Shiesh tawook Shawerma Chicken panee Unacceptability Histamine (mg/100gm) Min. 2.9 2.1 1.8 Max. 26.2 24.8 17.3 Mean ± S.E. 12.39±1.75+ 9.61±1.44 7.23±1.01 3 According to EOS (1996) * No. % 3 30 1 10 Zero Zero According to FDA (2001) ** No. % 4 40 3 30 2 20 * EOS (1996) → 20 mg/100 gm ** FDA (2001) → 10 mg/100 gm No.: Number of unaccepted samples + Significant differences (P < 0.05) Table (3): Concentration of tyramine (mg/100gm) in the examined samples of ready to eat chicken products and their acceptability according to EOS (1996) and FDA (2001) (n=10) Unacceptability Tyramine Samples Shiesh tawook Shawerma Chicken panee (mg/100gm) Min. 4.1 3.6 3.0 Max. 28.3 25.7 21.4 Mean ± S.E. 15.32±2.19+ 10.73±1.40 9.94±1.16 According to EOS (1996) * No. % 2 20 2 20 1 10 According to FDA (2001) ** No. % 5 50 4 40 5 50 *EOS (1996) → 20 mg/100 gm ** FDA (2001) → 10 mg/100 gm No.: Number of unaccepted samples + Significant differences (P < 0.05) Table (4): Concentration of putrescine (mg/100gm) in the examined samples of ready to eat chicken products and their acceptability according to EOS (1996) and FDA (2001) (n=10) Unacceptability Putrescine Samples Shiesh tawook Shawerma Chicken panee (mg/100gm) Min. 2.2 1.6 1.7 Max. 20.7 16.3 14.2 Mean ± S.E. 8.25±1.12+ 5.69±0.83 4.54±0.65 According to EOS (1996) * No. % 1 10 Zero Zero Zero Zero According to FDA (2001) ** No. % 3 30 2 20 1 10 * EOS (1996) → 20 mg/100 gm ** FDA (2001) → 10 mg/100 gm No.: Number of unaccepted samples + Significant differences (P < 0.05) Table (5): Concentration of tryptamine (mg/100gm) in the examined samples of ready to eat chicken products and their acceptability according to EOS (1996) and FDA (2001) (n=10) Unacceptability Tryptamine Samples Shiesh tawook Shawerma Chicken panee (mg/100gm) Min. 2.0 1.3 1.1 Max. 12.5 11.3 10.4 Mean ± S.E. 5.56±0.77NS 4.97±0.63 4.70±0.68 According to EOS (1996) * No. % Zero Zero Zero Zero Zero Zero According to FDA (2001) ** No. % 2 20 1 10 1 10 * EOS (1996) → 20 mg/100 gm ** FDA (2001) → 10 mg/100 gm NS= Non significant difference No.: Number of unaccepted samples N. B.: All the examined samples of ready to eat chicken products did not exceed the permissible limits of EOS (1996). 4 Discussion The determination of biogenic amines is important not only because of their toxicity (Edwards and Sandine, 1981 and Taylor, 1986), but also because of their potential use as quality markers (Ruiz – Capillas and Jimenéz – Colmenero, 2004 and Balamatsia et al., 2006). The results shown in table (1) revealed that APC (cfu/gm) in the examined samples of shiesh tawook, shawerma and chicken panee ranged from 1.9x104 to 2.7x107; 1.4x104 to 7.0x106 and 9.8x103 to 3.8x106, with mean values of 5.23x106 ± 1.17x106; 1.81x106 ± 0.33x106 and 4.69x105 ± 1.02x105, respectively. While, the concentration of biogenic amines (mg/100gm) in such examined samples ranged from 2.5 to 28.3; 1.3 to 25.7 and 1.1 to 18.3, with mean values of 9.86 ± 1.35; 7.50 ± 1.08 and 6.61 ± 0.79, respectively. The APC of the examined samples of ready to eat chicken products reflect probable post – processing cross contamination, since most microorganisms are expected to be inactivated during thermal processing (Apostolos et al., 2006). In general, the biogenic amines content increased earlier and more rapidly in chicken meat due to the presence of shorter muscular fibers in chicken, consequently, the presence of proteins with shorter chains, facilitating attack by proteolytic enzymes and increasing quantities of amino acid precursors for the biosynthesis of biogenic amines (Vinci and Antonelli, 2002 and Allen et al., 2004). In general, there were great fluctuations of biogenic amines content among types of products and in the same type of the product. These differences depend on many variables as the quali – quantitative composition of microflora, the chemico – physical variables, the hygienic procedure adopted during processing, the availability of precursors, the amount of meat used, types of ingredients added and the quality of the raw material (Silva and Glória, 2002 and Suzzi and Gardini, 2003). It was observed that there was a significant correlation between APC and the concentration of biogenic amines in the examined samples of sheish tawook and chicken panee, while a high significant correlation in the examined shawerma samples. This result is in agreement with the results of Suzzi and Gardini (2003) and Ntzimani et al. (2008) who recorded that high microbial counts, often unavoidably lead to considerable accumulation of biogenic amines, especially histamine, tyramine, putrescine and tryptamine, but it is not in agreement with Ayhat et al. (2000) who reported that there was no correlation between the number of isolates and histamine production by Enterobacteriaceae strains in culture medium. Table (2) showed that the concentration of histamine (mg/100gm) in the examined samples of shiesh tawook, shawerma and chicken panee ranged from 2.9 to 26.2; 2.1 to 24.8 and 1.8 to 17.3, with mean values of 12.39 ±1.75; 9.61 ± 1.44 and 7.23 ±1.01, respectively. Significant differences (p < 0.05) were reported between such examined samples as a result of their histamine content. Comparing the obtained results with the permissible limits recommended by EOS (1996) for histamine level, none of the examined chicken panee samples exceeded such permissible limits, while 30% and 10% of the examined shiesh tawook and shawerma samples, respectively, exceeded such permissible limits. However, on comparing the obtained results with the permissible limits recommended by FDA (2001) for histamine level, 40%, 30% and 20% of the examined samples of shiesh tawook, shawerma and chicken panee, respectively, exceeded such permissible limits. The obtained results were lower than Ntzimani et al. (2008) who recorded that the histamine concentration in smoked turkey breast fillets was 11.9 mg/100gm. The high level of histamine in the examined sheish tawook samples may be attributed to 5 the unfavorable temperature of processing, the presence of additives as pepper, tomatoes and other spices which play an important role in growth and multiplication of such histamine forming microorganisms (Fonberg – Broczek and Sawilska – Rautenstrauch, 1995), inadequate decrease in pH and using raw materials of low quality (Eerola et al., 1998 and Bover – Cid et al., 2000). However, the lowest histamine concentration in the examined chicken panee samples may be due to using large slices of chicken meat which constitute a protective layer from the surface microorganisms to penetrate the meat and cause degradation of amino acids (Fonberg – Broczek and Sawilska – Rautenstrauch, 1995). Histamine poisoning is a chemical intoxication of short incubation period (30 minutes to 1 hour). It is often manifested by a wide variety of symptoms as urticaria, oedema, localized inflammation, rash (Jean et al., 2001), nausea, vomition, diarrhea, abdominal cramps, hypotension, headache, palpitation, tingling, flushing, oral burning, bronchospasm, suffocation, severe respiratory distress and sweating (Hálasz et al., 1994 and Maijala and Eerola, 2002). Table (3) showed that the concentration of tyramine (mg/100gm) in the examined samples of shiesh tawook, shawerma and chicken panee ranged from 4.1 to 28.3; 3.6 to 25.7 and 3.0 to 21.4, with mean values of 15.32 ± 2.19; 10.73 ± 1.40 and 9.94 ± 1.16, respectively. Significant differences (p < 0.05) were reported between such examined samples as a result of their tyramine content. Comparing the obtained results with the permissible limits recommended by EOS (1996) for tyramine level, 20%, 20% and 10% of the examined shiesh tawook, shawerma and chicken panee samples, respectively, exceeded such permissible limits. However, on comparing the obtained results with the permissible limits recommended by FDA (2001) for tyramine level, 50%, 40% and 50% of the examined samples of shiesh tawook, shawerma and chicken panee, respectively, exceeded such permissible limits. Nearly similar results were obtained by Balamatsia et al. (2006), while lower results were reported by Silva and Glόria (2002) and higher results were obtained by Rokka et al. (2004) who recorded that the mean value of tyramine level in chicken cuts was 130 mg/kg and this result was attributed to high numbers of APC (106 – 107 cfu/gm), where accumulation of tyramine at bacterial numbers above 106 cfu/gm has been reported in different types of meat. Therefore tyramine should be proposed as a quality indicator of meat (Yano et al., 1995 and Pereira et al., 2001) The higher concentration of tyramine in the examined samples of sheish tawook may be due to the higher temperature which favored proteolytic and decarboxylase activities of microorganisms resulting in increased tyramine concentrations (Bover – Cid et al., 2000). Also, the addition of acidic materials to sheish tawook as onion juice lowers pH of the product, so activating the acidic bacteria to form biogenic amines. This result is supported by the theory that the formation of biogenic amines is a protective mechanism of bacteria against acidic environments (Maijala, 1994). However, low levels of tyramine in the examined shawema and chicken panee samples may be due to the absence of tyrosine – decarboxylase enzymes and / or non – expression of this activity under specific storage conditions (Balamatsia et al., 2006). The presence of other biogenic amines can potentiate the negative effect of tyramine on human health (Komprda et al., 2001). Tyramine acts mainly indirectly by releasing noradrenalin from the sympathetic nervous system which causes an increase of blood pressure by peripheral vasoconstriction and by increasing the cardiac output. Tyramine also dilates the pupils, dilates the peripheral tissue, causes 6 lacrimation and salivation, increases respiration and increases the blood sugar (Joosten, 1988). Regarding to table (4), the concentration of putrescine (mg/100gm) in the examined samples of shiesh tawook, shawerma and chicken panee ranged from 2.2 to 20.7; 1.6 to 16.3 and 1.7 to 14.2, with mean values of 8.25 ± 1.12; 5.69 ± 0.83 and 4.54 ± 0.65, respectively. Significant differences (p < 0.05) were reported between such examined samples as a result of their putrescine content. Comparing the obtained results with the permissible limits recommended by EOS (1996) for putrescine level, none of the examined shawerma and chicken panee samples exceeded such permissible limits, while 10% of the examined shiesh tawook exceeded the permissible limits of putrescine. However, on comparing the obtained results with the permissible limits recommended by FDA (2001) for putrescine level, 30%, 20% and 10% of the examined samples of shiesh tawook, shawerma and chicken panee, respectively, exceeded such permissible limits. Nearly similar results were obtained by Bover – Cid et al. (2000) and Saccani et al. (2005) who reported that the mean value of putrescine level in processed meat was 23 mg/kg, Eliassen et al. (2002) (in grilled breast 2 mg/kg) and Patsias et al. (2006) (in fried breast 0.7 mg/kg). The high concentration of putrescine in the examined samples of shiesh tawook indicated inappropriate treatment, poor hygienic levels of manufacturing process, using raw materials of poor quality (Kalač, 2006) and increased microbial contamination (Ruiz – Capillas et al., 2004 and Krausová et al., 2006). Therefore, Putrescine concentration may be considered as the limit for spoilage initiation (Apostolos et al., 2006) and objective indicator of acceptability of ready to eat chicken products (Pereira et al., 2001). Nevertheless, putrescine could be useful for post – operation patients, during wound healing and for the growth, maturation and regeneration of the intestinal mucosa of children and adults (Deloyer et al., 2001 and Deloyer et al., 2005). Table (5) showed that the concentration of tryptamine (mg/100gm) in the examined samples of shiesh tawook, shawerma and chicken panee ranged from 2.0 to 12.5; 1.3 to 11.3 and 1.1 to 10.4, with mean values of 5.56 ± 0.77; 4.97 ± 0.63 and 4.70 ± 0.68, respectively. Significant differences (p < 0.05) were reported between such examined samples as a result of their tryptamine content; none of the examined samples of ready to eat chicken products exceeded the permissible limits recommended by EOS (1996). However, in comparing the obtained results with the permissible limits recommended by FDA (2001) for tryptamine level, 20%, 10% and 10% of the examined samples of shiesh tawook, shawerma and chicken panee, respectively, exceeded such permissible limits. Tryptamine leads to severe headache, increased heart rate, fever, nausea, flushing, vomition, vision disturbances and hypertension (Maijala and Eerola, 2002). As an overall conclusion, the concentration of biogenic amines correlated well with the bacterial load of the examined ready to eat chicken products. Since biogenic amines are metabolites of microbial activity and resistant to heat treatment (Glória et al., 1999). So the profile of biogenic amines could be an important index in quality assurance of fresh and processed chicken meat (Bauer, 2006) and may be used as chemical indicators of chicken meat spoilage (Ntzimani et al., 2008). They have been considered as a freshness marker or as a bad conservation marker or as indicator of the microbial quality (Rokka et al., 2004), reflecting the hygienic quality of the raw material used and the hygienic conditions prevalent during its processing (Silva and 7 Glόria, 2002 and Coïsson et al., 2004). In particular, the study of biogenic amines quantities in meat as a function of conservation time could be a useful tool to control meat spoilage (Vinci and Antonelli, 2002), however the complexity of food matrix, the presence of potential interferences and the occurrence of several biogenic amines simultaneously are typical problems encountered in the analysis of food for biogenic amines. So, we confirm the importance of biogenic amines control as an important tool to establish better conditions of preservation of chicken products during their shelf life. Therefore, the greatest emphasis in the prevention of the formation of the biogenic amines should be placed on the high quality of used raw materials, the control of thawing, storage time and temperature of raw materials, the education on hygienic handling and manufacturing of raw materials, on the maintaining of hygienic standards during manufacturing process and the proper control of the individual technological steps. As well as, some microbial isolates may be added to degrade biogenic amines in order to prevent the presence of hazardous levels of amines in the final product (Leuschner and Hammes, 1998), but more information is needed to determine the effects of these treatments on organoleptic properties and their possible technological consequences. A PCR approach for the identification of decarboxylase genes in microbial strain would be helpful to complete the present study. References 1. 2. 3. 4. 5. 6. 7. 8. 9. Allen, G.; Green, D.; Bolton, G.; Jaykus, L. and Cope, G. (2004): Detection and identification of histamine producing bacteria associated with harvesting and primary processing of Tuna in north Carolina. J. Food Protec., 67: 79-81. Apostolos, p.; Irene, C.; Evangelos, K.P.; Ioannis, S. and Michael, G. K. (2006): Relation of biogenic amines to microbial and sensory changes of precooked chicken meat stored aerobically and under modified atmosphere packaging at 4οC. J. Eur. Food Res. Technol., 223: 683-689. Balamatsia, C. C.; Paleologos, E. K.; Kontominas, M. G. and Savvaidis, I. N. (2006): Correlation between microbial flora, sensory changes and biogenic amines formation in fresh chicken meat stored aerobically or under modified atmosphere packaging at 4οC: possible role of biogenic amines as spoilage indicators. Antonie van Leeuwenhoek 89, 9-17. Baston, O.; Tofan, l.; Moise, A. L. D. and Barna, O. (2008): Refrigerated chicken meat freshness correlation between easily hyrolisable nitrogen, pH value and biogenic amine contents. The Annals of the University Dunarea de Jos of Galati Fascicle VI – Food Technology, New Series Year II (XXXI). PP. 37-43. Bauer, F. (2006): Assessment of process quality by examination of the final product. 1. Assessment of the raw material. Fleischwirtschaft, 86(7): 106-107. Bover – Cid, S.; Izquierdo – Pulido, M. and Vidal – Carou, M. C. (2000): Influence of hygienic quality of raw materials on biogenic amines production during ripening and storage of dry fermented sausages. J. Food Protec., 63: 1544-1550. Bover – Cid, S.; Miguélez – Arrizado, M.; Latorre – Moratalla, L. L. and Vidal – Carou, M. C. (2006): Freezing of meat raw materials affects tyramine and diamine accumulation in spontaneously fermented sausage. J. Meat Science 72: 62-68. Byun, J. S.; Min, J. S.; Kim, I. S.; Kim, J. W.; Chung, M. S. and Lee, M. (2003): Comparison of indicators of microbial quality of meat during aerobic cold storage. J. Food Protec., 66: 1733-1737. Coïsson, J. D.; Cerutti, C.; Travaglia, F. and Arlorio, M. (2004): Production of biogenic amines in "Salamini italiani alla cacciatore PDO". J. Meat Sci., 67: 343-349. 8 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. 25. 26. 27. 28. 29. Deloyer, P.; Peulen, O. and Dandrifosse, G. (2001): Dietary polyamines and non – neoplastic growth and disease. European Journal of Gastroenterology and Hepatology 13: 1027-1032. Deloyer, P.; Peulen, O. and Dandrifosse, G. (2005): Intestinal effects of long – lasting spermine ingestion by suckling rats. J. Expermintal Physiology 90: 901-908. Durlu – Özkaya, F.; Alichanidis, E.; Litopoulou – Tzanetaki, E. and Tunail, N. (1999): Determination of biogenic amine content of Beyaz cheese and biogenic amine production ability of some lactic acid bacteria. Milchwissenschaft 54(12): 680-681. Edwards, S. T. and Sandine, W. E. (1981): Public health significance of amines in cheese. J. Dairy Science 64: 2431-2438. Eerola, H. S.; Roig – Sagués, A. X. and Hirvi, T. K. (1998): Biogenic amines in Finnish dry sausages. J. Food Safety 18: 127-138. Egyptian Organization for Standardization and Quality Control "EOS" (1996): Detection of poisons and control. Report No. 1796. Eliassen, K. A.; Reistad, R.; Risøen, U. and Rønning, H. F. (2002): Dietary polyamines. J. Food Chemistry 78: 273-280. Feldman, D.; Hoffman, R. and Simpson, J. (2003): The solution for data analysis and presentation graphics. 2nd Ed., Abacus Lancripts, Inc., Barkeley, CA, USA. Fonberg – Broczek, M. and Sawilska – Rautenstrauch, D. (1995): Level of histamine and tyramine in ripening cheese. Rocz Panstw Zakl Hig. 46(3): 243-246. Food and Drug Administration "FDA" (2001): Hazards and Control guidance, 3rd ed., Center of Food Safety and Nutrition, Washington, USA. Geornaras, I.; Dykes, G. A. and von Holy, A. (1995): Biogenic amine formation by chicken – associated spoilage and pathogenic bacteria. Lett. Appl. Microbial., 21: 164166. Glória, M. B. A.; Daeschel, M. A.; Craven, C. and Hilderbrand, K. S. (1999): Histamine and other biogenic amines in albacore tuna. J. Aquat. Food Prod. Technol., 8(4): 55-69. Halász, A., Barath, A., Simon – Sarkadi, L. and Holzapfel, W. (1994): Biogenic amines and their production by microorganisms in food. Trends in Food Science and Technology 5: 42-49. International Commission on Microbiological Specifications for Foods "ICMSF" (1996): Microorganisms in foods. Vol. I. 2nd Ed., Univ. Toronta, Canada. Black Academic and Professional, London. Jean, D. C.; Caterina, C.; Fabiano, T. and Marco, A. (2001): Production of biogenic amines in Italian salami "fermented sausage". J. Meat Science 67(4): 607-616. Joosten, H. M. L. G. (1988): The biogenic amine contents of Dutch cheese and their toxicological significance. Neth. Milk Dairy J. 42: 25-42. Kalač, P. (2006): Biologically active polyamines in beef, pork and meat products: A review. J. Meat Science 73: 1-11. Kim, S. H.; Field, K. G.; Chang, D. S.; Wei, C. I. and An, H. (2001): Identification of bacteria crucial to histamine accumulation in pacific mackerel during storage. J. Food Protec., 64: 1556-1564. Komprda, T.; Neznalova, J.; Standara, S. and Bover – Cid, S. (2001): Effect of starter culture and storage temperature on the content of biogenic amines in dry fermented sausage poličan. J. Meat Science 59: 267-276. Krausová, P.; Kalač, P.; Křižek M. and Pelikánová, T. (2006): Content of biologically active polyamines in livers of cattle, pigs and chickens after animal slaughter. J. Meat Science 73: 640-644. 9 30. 31. 32. 33. 34. 35. 36. 37. 38. 39. 40. 41. 42. 43. 44. 45. Leuschner, R. G. K. and Hammes, W. P. (1998): Degradation of histamine and tyramine by Brevibacterium linens during surface ripening of Munster cheese. J. Food Protec., 61: 874-878. Lonvaud – Funel A. (2001): Biogenic amines in wines: role of lactic acid bacteria. FEMS Microbiology Letters 199: 9-13. Maijala, R. (1994): Formation of biogenic amines in dry sausage with special reference to raw materials, lactic acid bacteria, pH decrease, temperature and time. Ph. D. Thesis, University of Helsinki, Finland. Maijala, R. and Eerola, S. (2002): Biogenic amines. Veterinary and Food Research Institute, Helsinki Finland. Elsevier Science Ltd. Moret, S. and Conte, L. (1996): High performance liquid chromatographic evaluation of biogenic amines in foods. J. Chromatography 729:363-369. Ntzimani, A. G.; Paleologos, E. K.; Savvaidis, I. N. and Kontominas, M. G. (2008): Formation of biogenic amines and relation to microbial flora and sensory changes in smoked turkey breast fillets stored under various packaging conditions at 4οC. J. Food Microbiol., 25: 509-517. Paleologos, E. K.; Chytiri, S. D.; Savvaidis, I. N.; Kontominas, M. G. (2003): Determination of biogenic amines as their benzoyl derivatives, after cloud point extraction with micellar liquid chromatographic separation. J. Chromatogr. A 1010, 217-224. Patsias, A.; Chouliara, I.; Paleologos, E. K.; Savvaidis, I. and Kontominas, M. G. (2006): Relation of biogenic amines to microbial and sensory changes of precooked chicken meat stored aerobically or under modified atmosphere packaging at 4οC. European Food Research and Technology 223: 683-689. Pereira, C. I.; Barreto Crespo, M. T.; San Romao, M. V. (2001): Evidence for proteolytic activity and biogenic amines production in Lactobacillus curvatus and L. homohiochii. Int. J. Food Microbiol., 68: 211-216. Roig, A. (2002): The role of biogenic amines as quality indicators. In D. M. L. Morgan, T. Hirvi, G. Danrifosse, P. Deloyer and White Ann (Eds.), Food Science and Technology COST 917: Biogenically active amines in food: Vol. VI. (pp. 171-174). Luxembourg: European Cooperation on Scientific and Technical Research. Office for Official Publications of the European Communities. Rokka, M.; Eerola, S.; Smolander, M.; Alakomi, H. L. and Ahvenainen, R. (2004): Monitoring of the quality of modified atmosphere packaged broiler chicken cuts stored in different temperature conditions. Biogenic amines as quality indicating metabolites. J. Food Control 15: 601-607. Ruiz – Capillas, C. and Jimenéz – Colmenero, F. (2004): Biogenic amines in meat and meat products. Critical Reviewers in Food Science and Nutrition 44: 489-499. Ruiz – Capillas, C.; Cofrades, S.; Serrano, A. and Jimenéz – Colmenero, F. (2004): Biogenic amines in restructured beef steaks as affected by added walnuts and cold storage. J. Food Protec., 67: 607-609. Saccani, G.; Tanzi, E.; Pastore, P.; Cavalli, S. and Rey, M. (2005): Determination of biogenic amines in fresh and processed meat by suppressed ion chromatography – mass spectrometry using a cation – exchange column. J. Chromatogr. A., 1082(1): 43-50. Silva, C. M. G. and Glόria, M. B. A. (2002): Bioactive amines in chicken breast and thigh after slaughter and during storage at 4 ± 1οC and in chicken – based meat products. J. Food Chem., 78: 241-248. Suzzi, G, and Gardini, F. (2003): Biogenic amines in dry fermented sausages: a review. Int. J. Food Microbiol., 88: 41-54. 10 Taylor, S. L. (1986): Histamine food poisoning. Toxicology and clinical aspects. Critical Reviews in Toxicology 17: 91-117. Veciana – Nogués, M. T.; Marine – Font, A. and Vidal – Carou, M. C. (1997): Biogenic amines as hygienic quality indicators of tuna. Relationships with microbial counts, ATP – related compounds, volatile amines and organoleptic changes. J. Agriculture and Food Chemistry 45: 2036-2041. Vinci, G. and Antonelli, M. (2002): Biogenic amines: quality index of freshness in red and white meat. J. Food Control 13:519-524. Yano, Y.; Kataho, N.; Watanabe, M. and Nakamura, T. (1995): Changes in the concentration of biogenic amines and application of tyramine sensor during storage of beef. J. Food Chemistry 54: 155-159. 46. 47. 48. 49. الملخص العربى العالقة بين محتوى األمينات الحيوية والحمل البكتيري لبعض منتجات الدواجن الجاهزة لألكل جيهان سيد أحمد عفيفى ,ريهام عبد العزيز أمين قسم مراقبة األغذية – كلية الطب البيطرى بمشتهر – جامعة بنها إن للحوووم الوودواجن أهميووة كبيوورة فووغ غووذام المسووتهلت لمووا نحتويووع موون قيمووة عاليووة موون األحمووا األمينيووة والوودهون والفيتامينووات والمعوواتن والتووغ بوودورها نوووحر علووى ووحة وحيويووة المسووتهلت ونعتبوور أيم وا ك موون أك وور مصاتر التلوث بالميكروبات التغ نساعد على نحويل األحموا األمينيوة الموجووتة فوغ اللحووم إلوى مووات أ ورى نسمى باألمينات الحيوية والتوغ نووحر علوى وحة المسوتهلت بشوكل طيور حينموا نتجواوا الحودوت المسومو بهوا لتواجدها فغ هذه المنتجات . واوو ولذلت أجريوت هوذه الدراسوة علوى عودت 30عينوة مون منتجوات الودواجن الجواهزة لألكول ونشومل الشوي والشاورمة والبانيع من مطواعم مختلفوة بمحواف تغ الوليوبيوة والةربيوة وقود أونوحت النتواوس أن متوسو نركيوز الهسوووتامين ل التيووورامينل البيونرسوووين والتربتوووامين مجوووم 100جم)هوووو 1.75 + 12.39ل 2.19 + 15.32ل ووواوو بينموووا كانوووت 1.44 +9.61ل 1.40 + 10.73ل 1.12 + 8.25و 0.77 + 5.56فوووغ عينوووات الشوووي 0.83 + 5.69و 0.63 + 4.97فغ عينات الشاورمة وأ يرا ك كانوت 1.01 + 7.23ل 1.16 + 9.94ل + 4.54 واوو هوغ 0.65و 0.68 + 4.70فغ عينات البانيع على التوالغ .ومن هذه النتاوس انمح أن عينات الشوي أك ر منتجات الدواجن احتوام على نلت األمينات الحيوية السامة موارنة بمنتجات الشاورمة والبانيع وبموارنة النتاوس بالحدوت المسمو بها 20مجم 100جم) بالموا وفات الوياسوية المصورية )1996كموا وجود اوو والشاورمة والبانية على الترنيب قود ااتت عون الحودوت أن %20ل %20و %10من عينات الشي المسمو بها للهستامين .بينما على الجانب اآل ر كانت جميع العينات فغ حدوت النسب المسومو بهوا بالنسوبة اوو أعلى مون الحودوت المسومو بهوا لتركيز التربتامين .وقد احتوت فو %30و %10من عينات الشي للهستامين والبيونرسين 20مجم )%على الترنيب .وأيما ك قد نم تراسوة العالقوة بوين الحمول البكتيوري ونركيوز األمينات الحيوية لهذه المنتجات. وأ يرا ك نم تراسة األهمية الصحية لهذه األمينات الحيوية ومدى نأحيرها على وحة المسوتهلت وكيفيوة الحود مون نكوينها وأحرها المارة . 11