Poka Yoke - Workforce Solutions

advertisement

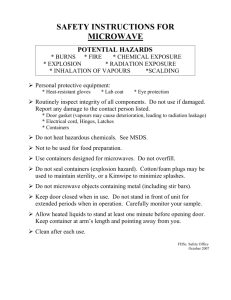

Poka-Yoke Shigeo Shingo recognized three types of poka-yoke for detecting and preventing errors: 1. The contact method identifies product defects by testing the product's shape, size, color, or other physical attributes. 2. The fixed-value (or constant number) method alerts the operator if a certain number of movements are not made. 3. The motion-step (or sequence) method determines whether the prescribed steps of the process have been followed. Either the operator is alerted when a mistake is about to be made, or the poka-yoke device actually prevents the mistake from being made. An alert system is called a warning poka-yoke, a preventive device would be a control poka-yoke. Shingo argued that errors are inevitable in any process, but that if appropriate pokayokes are implemented, mistakes could be caught quickly and prevented from resulting in defects or errors. By eliminating defects at the source, the cost of mistakes is reduced. Source: Wikipedia Examples SIM cards used in cellular phones has its upper left corner trimmed diagonally to guide the card correctly into position. Microwave ovens--a door switch automatically disconnects the activation button when the door of the oven is opened. As a result, it is impossible to cook anything in a microwave oven unless the door is fully closed. Car keys--the inability to remove a car key from the ignition switch of an automobile if the automatic transmission is not first put in the "Park" position, so that the driver cannot leave the car in an unsafe parking condition where the wheels are not locked against movement. Source: www.campbell.berry.edu/pokayoke Created by funding from WIRED NW