Lean Operations - Prism Web Pages

advertisement

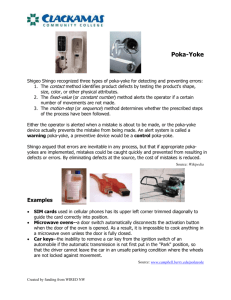

Lean Operations “Eliminate Waste Through Continuous Improvement” A Little History! Benjamin Franklin Poor Richard’s Almanac: He that idly loses 5s. [shillings] worth of time, loses 5s., and might as prudently throw 5s. into the river. He that loses 5s. not only loses that sum, but all the other advantages that might be made by turning it in dealing, which, by the time a young man becomes old, amounts to a comfortable bag of money." A Little History! Gilbreth Saw that masons bent over to pick up bricks from the ground. The bricklayer was therefore lowering and raising his entire upper body to get a 5 pound (2.3 kg) brick but this inefficiency had been built into the job through long practice. Introduction of a non-stooping scaffold, which delivered the bricks at waist level, allowed masons to work about three times as quickly, and with less effort. A Little History! Ford: Eliminate Waste "I believe that the average farmer puts to a really useful purpose only about 5 %. of the energy he expends. … Not only is everything done by hand, but seldom is a thought given to a logical arrangement. A farmer doing his chores will walk up and down a rickety ladder a dozen times. He will carry water for years instead of putting in a few lengths of pipe. His whole idea, when there is extra work to do, is to hire extra men. He thinks of putting money into improvements as an expense. … It is waste motion— waste effort— that makes farm prices high and profits low." A Little History! Ford: Design for manufacturing Start with an article that suits and then study to find some way of eliminating the entirely useless parts. This applies to everything— a shoe, a dress, a house, a piece of machinery, a railroad, a steamship, an airplane. As we cut out useless parts and simplify necessary ones, we also cut down the cost of making. ...But also it is to be remembered that all the parts are designed so that they can be most easily made." A Little History! Ohno – put ideas into practice systematically “When bombarded with questions from our group on what inspired his thinking, Ohno just laughed and said he learned it all from Henry Ford's book." Waste: Classification Waste from overproduction Inventory waste Waste from waiting time Transportation waste Processing waste Waste of motion Waste from product defects TPS: Toyota Production System A system that continually searches for and eliminates waste throughout the value chain. Views every enterprise activity as an operation and applies its waste reduction concepts to each activity - from Customers to the Board of Directors to Support Staff to Production Plants to Suppliers. TPS: Toyota Production System Reducing Waste: Quality at Source Failsafe design (Poka-Yoke) Stopping work immediately when problem occurs (Jidoka) Line-stopping empowerment (Andon) Poka-Yoke Poka-Yoke Poka-yoke page: http://csob.berry.edu/faculty/jgrout/pokayoke.shtml Jidoka Andon Reducing Waste: Quality at Source Defects found at: Impact to the Company: Current Process · Very Minor Next Process · Minor Delay End of Line Final Inspection End User · Rework · Significant · Warranty Rework Costs · Rescheduling of work · Delay in · Administrative Delivery Costs · Additional · Reputation Inspection · Loss of Market Share Reducing Waste: Increase Problem Visibility Inventory Supply Fluctuations Missed Due Dates Excessive Paperwork Scrap & Rework Machine Downtime Reducing Waste: Push versus Pull System Raw Material Supplier Final Assembly Customer FGI PUSH Raw Material Supplier Final Assembly Customer FGI PULL Information Flow Material Flow TPS System uses Kanbans Reducing Waste: From Functional Layout… Production Control Production Control Production Control Roof Cut Roof Cut Roof Cut Base Cut Base Cut Base Cut FA FA FA Base Assy Base Assy Base Assy QC QC QC ...to Cell Layout Production Control Production Control Production Control Roof Cut Base Cut Roof Cut Base Cut Roof Cut Base Cut FA Base Assy FA Base Assy FA Base Assy Reducing Waste: Cut Batch Sizes Example Process: 0 1 2 3 4 8 A B C D 1 min/job 1 min/job 1 min/job 1 min/job Batch Mfg. (Lot Size = 4) 4 A B 4 C D 0 1 2 3 4 8 4 16 Time 4 16 Time Flow Mfg. (Lot Size = 1) 1 1 A B 1 C 1 D Synchronize: Heijunka Mixed, Level/Balanced Production Batch Production Schedule (AAAABBBB...) Apr/12.........15..................30 Mixed Production Schedule (ABAB...) Apr/12..........15...................30 Products A B FGI FGI time time Continuous Improvement: Kaizen Increase visibility of waste Standardize work Targeted improvements Active worker involvement Supplier involvement Time for experimentation Exploratory stress TPS: Toyota Production System A system that continually searches for and eliminates waste throughout the value chain. Poka-Yoke Jidoka Andon Kanban Heijunka Kaizen Management By Stress: Does “S” in TPS Stand for Stress (1)? “Empower employees” Employees responsible for errors. “Drive out waste” No slack in the human system. “Kaizen” Improvements discovered by workers are co-opted by management. “Workers design their jobs” Workers do industrial engineering jobs without the pay. Management By Stress: Does “S” in TPS Stand for Stress (2)? “Reduce indirect labor” Make workers do management’s job. “Reduced buffers” More stress and less room for error or fatigue. “Respect for workers” As long as workers define their personal goals as satisfying management’s agenda… “Productivity enhancements are dramatic” Workers work real hard, with little spare time. If You’re Curious to know more.. Lean Blog: http://kanban.blogspot.com/ Books: Ohno, Taiichi (1988), Toyota Production System: Beyond Large-Scale Production, Productivity Press. Womack, James P., Jones, Daniel T., and Roos, Daniel (1991), The Machine That Changed the World: The Story of Lean Production, Harper Perennial Womack, James P. and Jones, Daniel T. (1998), Lean Thinking Free Press. Levinson, William A. (2002), Henry Ford's Lean Vision: Enduring Principles from the First Ford Motor Plant, Productivity Press Ford, Henry and Crowther, Samuel (2003), My Life and Work, Kessinger Press.