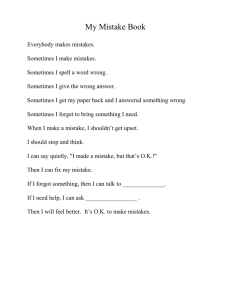

General Information • • General Information o o o o General Information Human mistake: 77.8% General Information Poka Yokes ensure that the right conditions exist before a process step is executed, and thus preventing defects from occurring in the first place. Where this is not possible, Poka Yokes perform a detective function, eliminating defects in the process as early as possible. Poka Yoke is any mechanism in a Lean manufacturing process that helps to avoid mistakes. Its purpose is to eliminate product defects by preventing, correcting, or drawing attention to human errors as they occur. POKA YOKE : A poka-yoke is any mechanism in any process that helps an equipment operator avoids mistakes. Its purpose is to eliminate product defects by preven ng, correc ng, or drawing a en on to human errors as they occur. Poka-yoke can be implemented at any step of a manufacturing process where something can go wrong or an error can be made. For example, a #xture that holds pieces for processing might be modi#ed to only allow pieces to be held in the correct orienta on, or a digital counter might track the number of spot welds on each piece to ensure that the worker executes the correct number of weld General Information QC & test SOP Mistake proof 0 % The defect could be decreased to ZERO by applying mistake proof properly. General Information Type 1: zero accident but the investment is higher than other types. Type 2: Accident can happen if driver didn’t notice the red light, investment is less than type 1. Type 3: it’s only one reminding to bus driver, investment is less than type 1 & 2. General Information Mistake proof on elastic band broken General Information Mistake proof for packing errors To detect leg in or out automatically General Information Automatic Elastic band machine (cutting & sewing) General Information Wrong size • Double check in Dry room General Information To avoid packing errors by control label & tag QTY General Information Mold prevention Automatic dehumidifier Alarm system while humidity is exceed the above limit. Manual check by Aqua boy. General Information Broken needle control Broken needle control ND reject if any broken needle General Information Sewing Mistake Proof General Information Thanks!