File - 140T Jamalpur Cranes

advertisement

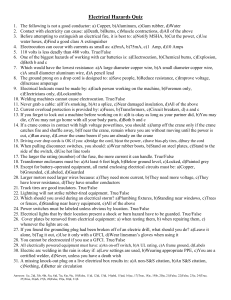

Minutes of Conference held at JMP on 02.09.11 and 03.09.11 for 140T Crane (Gottwald Design) spares requirement and repair requirement Present: Rly. Board Representative: Sri Manish Jain/ DME (P)-II Jamalpur Representative: Sri Animesh Kr. Sinha/CWM/JMP Sri C. P. Sharma/ Dy.CME/Cr/JMP Sri G. C. Rao/ AWM/Crane/JMP RDSO/LKO Representative: Sri Pankaj Saxena/ADE/RDSO/LKO ER HQ Representative: Sri S. K. Biswas/ Dy.CME/HQ/ER Sri J. K. Pal/ SME/HQ-I/ER Firm’s Representative Mr. Anmol Batra/Cummins/Kol. Mr. J.D.Petkar/Mechanica/Pune Mr. Binod Kumar/ Hi-tech/Delhi Crane User Representative: (1) Sri B. Lakra, CMPE/NFR (2) (3) Sri A. K. Gupta, CMPE/SECR (4) (5) Sri A. K. Gautam, Sr. DME (O&F)/ALD (6) (7) Sri S. N. Roy, Sr.DME (C&W)/SEE (8) (9) Sri B. K. Pandey, Sr.DME/Gonda (10) (11) Sri P.K. Mukhopadhyayay,DME(P)/ER/ASN (12) (13) Sri A. Gupta, DME/NFR/NJP (14) (15) Sri B. Nath, DME/NFR/NBQ (16) (17) Sri A.K. Srivastava, DME/NR (18) (19) Sri S. C.Behra, SME (HQ)/SER/GRC (20) (21) Sri S.K. Tiwari, AME/ER/SBG (22) (23) Sri J.P. Singh, AME/NFR/NGC (24) (25) Sri R. Rangarao, ADME/SECR/BIA (26) (27) Sri Chintamani, ADME/SECR/BSP (28) (29) Sri P.S. Kumar, AME/NED (30) (31) Sri B.K.Saha, ADME/Gondia Sri Satish Kumar, CMPE/NER Sri A. K. Shivhare, Dy.CME/HQ/NCR Sri K. N. S. Yadav, Sr. DME (P)/DHN Sri N. N. Sarkar, Dy.CME (OP)/SDAH Sri C.S. Yadav,DME(P)/NR/LKO Sri K.L. Saini, DME/WR/RTM Sri C.H.V. Ramanna, DME/ECoR/VSKP Sri Shivaji Kadam, DME/CR/Ajni Sri G.S.Reddy, AME/ECoR/BBS Sri B.Sampat Kumar, AM E/SCR/PAU Sri A.K.Gupta, ADME/ECR/SEE Sri K.K.Deva, ADME/NFR/TSK Sri D. Kumar, ADME (P)/ECR/MGS Sri P. Behra, ADME/ECoR Sri K. Raja, ADME/SR/TVC This meeting conducted as follow-up to Crane Review Meeting conducted at RDSO on 29-7-11. 1. CAMC of Cummins Engine: (Item-4, decision-4 of RDSO-MOM) M/s Cummins was represented by Mr. Anmol Batra (Cummins/Eastern Zone/Kol). Points discussed were as follows: S.N. POINT EXISTING PROPOSAL 1 No of visits 8 visits per annum 2 Payment terms Pro rata on annual basis for AMC& bi-monthly submission of bills 3 Response time to Report for Brake Down Repair <50Km………….within12hrs <51200Km………….within24hrs >201Km……… within48 hrs TO BE REVISED AS 4 Regular visits + 1B check visit +1C check visit per annum to be equally inter-spread to the extent possible Actual basis. Billing per visit or bimonthly as suitable for firm. Response time for emergency Break Down at site should be not more than 02 hours for <50 kms. The service engineer will move along with required spares according to preliminary message from site. If crane returns to depot , it should be attended within 03 days. For > 201 Kms it should be <24 hrs except NFR (east of New JalpaiGuri) and J&K where it will be 48 hrs. Page 1 of 14 Detailing of consumables during6 visits Lump Sum provision 4 5 Materials List Lump Sum provision Detailed break-up of Consumable and material list to be give for 4 regular visits + B check + C check. Individual price of mandatory parts to be replaced in schedules shall be mentioned. Firm will exempt cost for consumables provided by Rlys. Rlys. will provide manpower , available tools & space free of cost. a)Mandatory list as per Para 4 above. b) Materials which may be required with individual cost- optimal list. c) List of material with individual costto be kept per crane. d) List of material with individual cost- to be kept per zone. 6 7 Inclusive clause Existing proposal does not mention AMC to be effective from date of expiry of std. warranty for new or POH/MLR engine. Exclusive clause a) Failure due to operational fault/accident/unusual operating environment b) Replacement of exhaust silencer/piping/battery c) Replacement of cylinder block, crank shaft, cam shaft,, cylinder head, liner, piston, piston rings, PT Pump, Gear Pump, Cylinder casting, Turbo wheel and shaft, injector body. d) Radiator and its accessoriesHyd. Motor, Hyd Pump, Fan & Hub, ECPG/Governor controller, Fuel actuator, Wiring Harness & compressor. e) E-check & major overhauling If std warranty for new or POH/MLR engine is alive, the coverage of these parts shall be according to std warranty. 8 On site Requisition Not clear 9 Payment agency (Divn/JMP) Not clear 10 Inter-dealer mapping In case of B/Down at site, M/s Cummins will depute rep within shortest possible time. However last leg may have to be covered by train. For which the engineer will report within 2 hours at the Railway Station. Cummins representative to be authorized to travel by train/Loco/TC/ATR on authorization given by ART I/C or AME(P)/DME(P) or higher office. Parts will be replaced as required however Service Report to be accepted by Rlys. For post facto approval and payments to Cummins. Jmp(W) shall have a centralized contract but modalities of payment by Div as in case of DEMU engines. Reference (1) ICF Rate Contract No.MD/DMU/HHP/ECHECK/RC/CIL/2009-11/1 DT.07-5-10 specifying in para21.1 that payment will be made by Zonal Rlys. (2)ICF Rate Contract No.MD/DMU/HHP/DCHECK/RC/CIL/2010/12-2 DT.16-1210. CAMC will be through nearest Cummins dealer with respect to Crane Page 2 of 14 11 Contract Value 12 Training 13 Availability / MTBF / Maximum b/down window for 1 failure based location but in case of b/down in other area, inter dealer mapping to be ensured by Cummins. to be modified by Cummins as per para-1 above. M/s Cummins to give know- how regarding daily and weekly checking of engine in proper procedure to users. To be specified considering low usage hours and intermittent use. The service level should improve when direct contract with Cummins is done at the same cost as being paid at present by users individually. (a) Rly. Bd’s Comments: In spite of AMC or CAMC, user’s responsibility will be final to avoid any delay of Break Down of the crane. (b) CWM Comments: Determination of Contract & other clauses of GCC must be followed. (c) Final decision of house: All crane users agreed for central CAMC of engine. ZRs will ensure provision of funds. (d) Crane list, location & model of engine to be given by JMP on demand. (e) The contract could later be extended to cover E-check/POH of the main engine which could be synchronized with POH of the crane at JMPW. DECISION TAKEN: Fresh offer to be submitted by CUMMINS at the earliest covering the above points , which will be processed by JMP for approval and entering into contract. 1.2 AMC of SLI system: (Item-4, decision-3 of RDSO-MOM) Points discussed were as follows: (a) All users are interested for AMC on SLI. JMPW too recommends it. However costs being charged at present needs to be critically looked at. (b) All crane users present at seminar were explained the seven points given by JMP to E. Rly./HQ and RDSO/LKO for up gradation of SLI system. Three more points (viii to x) were discussed. (i) Indication & warning of tilted angle of Prop. (Horizontality of crane). (ii) Automatic indication & control of Prop position. (iii) Automatic indication of CWT status in new design. (iv) Automatic selection/indication by SLI clarifying whether main or Aux. hook is under use for both designs not considered necessary. (v) Automatic indication of tail radius in new design. (vi) For more accuracy of actual load, shear pin in lieu of load cell for new design & old design. (vii) SLI indication for auxiliary hook of old design cranes. (viii) Hour meter provision – not required as engine hour meter is already avl. (ix) Audio alarms in addition to visual – not considered necessary. (x) Event recorder (c) One or two users proposed SLI cut off in case of abnormal wind force experienced by load resulting in swaying of load (e.g. in case of high wind speed) Calculations justifying wind speed sensor will be submitted by SLI manufacturer to RDSO for scrutiny. If considered necessary, it may be installed on cranes in coastal areas on trial basis only. (d) Users did not suggest any other point during seminar, other than (b) (vi) & (c) above. DECISION TAKEN: (a) Modifications/up gradation suggested above to be developed by SLI manufacturers and to be submitted to RDSO for approval. (b) Any change in design of SLI should have approval of RDSO and JMP works. Users should not undertake any modification (as done by TPJ) on their own. Page 3 of 14 1.3 Current status of AMC by users (Item-4, decision-1 of RDSO-MOM) (a) SLI- Out of 52 users only 33 having AMC. JMPW recommends that SLI cards must be under AMC as know-how of mother board & cards not available with Elect.sec./JMPW. (b) Main Engine – Out of 52 users only 17 having AMC. JMP works recommends that engine must be under AMC. (c) Full Crane except main engine – About 15 users are having this type of AMC. (d) Efforts on for Centralized AMC for main engine. Rate recd earlier is Rs 5 lacs + per day charges for 1 year covering B&C checks AND another 4.68 lacs for D check after 2 yrs. NOTE – JMPW opined that those users having part/full crane under AMC should not call JMP to attend that particular part of crane covered under AMC, except in very exceptional circumstances. DECISION TAKEN: Any user who enters into AMC for any part of crane should send intimation/agreement copy to JMPW as well. Presently this information is received through JMP staff attending the crane. 2. Material for maintenance of Crane: (Item-3, decision-4B of RDSO-MOM) Points discussed were as follows: 2.1 Emergency Spares Users had been requested to submit list of emergency spares, as proposed by them. Summary of their submission is as below: (1) Crane No. 144010 / KURLA/CR 227 items (2) Crane No. 143004/SBG/ER NOT SUBMITTED (3) Crane No. 144020 /ERS/SR NOT SUBMITTED. (4) Crane No. 143006/KBJ/ECoR NOT SUBMITTED. (5) Crane No. 144006/TNP/SR NOT SUBMITTED. (6) Crane No. 144019/TPJ/SR NOT SUBMITTED. (7) Crane No. 143010/DNR/ECR 37 items (8) Crane No. 144005/SBP/ECoR NOT SUBMITTED (9) Crane No. 142033/MGS/ECR 06 items. (10) Crane No. 142042/TSK/NFR 42 items (11) Crane No. 143002/GHY/NFR 40 items (12) Crane No. 142032/BSP/SECR 25 items (13) Crane No. 142271/DLI/NR NOT SUBMITTED (14) Crane No. 142270/CNB/NCR 08 items (15) Crane No. 142038/LKO/NR NOT SUBMITTED (16) Crane No. 142037/HWH/ER (17) Crane No. 144007/RPH/ER (18) Crane No. 142039/ASN/ER (19) Crane No. 143007/BGA/ER (20) Crane No. 144015/Rajkot/WR (21) Crane No. 144011/NBQ/NFR (22) Crane No. 144008/Miraj/CR (23) Crane No. 144001/VSKP/ECoR (24) Crane No. 142269/NJP/NFR (25) Crane No. 142265/RTM/WR (26) Crane No. 143009/BKSC/SER (27) Crane No. 142266/GONDA/NER (28) Crane No. 143003/SEE/ECR (29) Crane No. 144021/GONDIA/SECR (30) Crane No. 142041/BIA/SECR (31) Crane No. 144012/PURNA/SCR (32) Crane No. 144003/AJNI/CR NOT SUBMITTED NOT SUBMITTED 160 items 131 items NOT SUBMITTED 132 items NOT SUBMITTED 53 items 36 items 18 items NOT SUBMITTED 101 items NOT SUBMITTED opined it will follow JMP recommendations. NOT SUBMITTED NOT SUBMITTED NOT SUBMITTED Page 4 of 14 SUMMARY: a) Some users stated that List of Emergency Spares may be finalized by JMPW. b) 17 out of 32 users above have not submitted any list of emergency spares. Another 20 users (Div. level) did not attend this seminar. Bd. stated that list of emergency spares submitted by JMP shall be approved after getting opinion of users. Seeing the above response Bd. will be requested separately to approve the reviewed list (dt. 26-09-11) of Emergency Spares (Cat-A91 items & Cat-B-624 items) so that emergency spares could be procured through Rate Contract under process at E.Rly/H.Q. from 26-09-11(Lists attached). The lists should clearly identify the exception between old and new design spares. c) Parel stocks 2 crane sets of emergency spares for 12 Nos. Old Design Crane & 01 Crane Set for 04 nos. New Design Crane. For emergency spares, indents are generated by users in case of Cowans Crane. d) In 2012-13 JMP will have 22 Old Design Cranes & 36 New Design Cranes, many of them aged. e) If Parel formula is copied, one crane set of emergency spares per five nos. of cranes (whether old design or new design) shall be required. However in view of large population to avoid nonmoving items, it was decided to keep 2 sets of old design and 3 sets of new design crane spares. 2.2 Rate Contract (Item-3, decision-1&3 of RDSO-MOM) Points discussed were as follows: 1. JMPW had submitted to E. Rly. H. Q a list of 1259 Nos. items previously for procurement through RC. RC for 611 items (sorted out by HQ- in sixteen Cases) were under process by Eastern Railway HQ. Two cases for 40 types of Hoses finalized and valid up to 30.09.12. Copies have been uploaded on crane web-sitre for ready reference. a) RC No.04/140T/Crane/ Hose Assly/RC on M/s Hydraulic Syndicate for 32 types of Hoses. b) RC No.04/140T/Crane/ Hose Assly/RC on M/s Hydrocrimp for 08 types of Hoses. Users may utilize these two contracts as per their requirement. 2. Bd. advised Dy.CME/HQ/ER to finalize the cases early who advised Dy.CME/Cr/Jmp to review the list of remaining items. Target for finalizing the RC should be intimated by ER HQ to Board latest by 10-Oct-2011. Action taken by JMPW after the meeting: a) JMPW has reviewed (added/deleted) the R.C list items and sent it to E.R.HQ on 23-0911 ( Total 788 items now) , so as to cover up to future MLR requirements of major items through RC, just like Parel. This will automatically cover future POH requirements & Emergency Spares ( Cat-A-91 items & Cat-B-624) items too. 73 out of 161 reviewed Ccategory items are included in reviewed RC list of 788 items. b) For minor items not in extended RC list, requirements shall be covered through estimates or otherwise. Spares for regular use to be purchased/Stocked at depot level (“C” Category Items) (Item-3, decision-4A of RDSO-MOM) 2.3 (1) (2) (3) (4) (5) (6) (7) (8) Users had been requested to submit list of regular use spares to be purchased/stocked at depot level, as proposed by them. Summary of their submission is as below: Crane No. 144010 / KURLA/CR NOT SUBMITTED Crane No. 143004/SBG/ER 151 items Crane No. 144020 /ERS/SR NOT SUBMITTED. Crane No. 143006/KBJ/ECoR NOT SUBMITTED. Crane No. 144006/TNP/SR 12 items Crane No. 144019/TPJ/SR NOT SUBMITTED. Crane No. 143010/DNR/ECR 06 items Crane No. 144005/SBP/ECoR NOT SUBMITTED Page 5 of 14 (9) (10) (11) (12) (13) (14) (15) (16) (17) (18) (19) (20) (21) (22) (23) (24) (25) (26) (27) (28) (29) (30) (31) (32) Crane No. 142033/MGS/ECR Crane No. 142042/TSK/NFR Crane No. 143002/GHY/NFR Crane No. 142032/BSP/SECR Crane No. 142271/DLI/NR Crane No. 142270/CNB/NCR Crane No. 142038/LKO/NR Crane No. 142037/HWH/ER Crane No. 144007/RPH/ER Crane No. 142039/ASN/ER Crane No. 143007/BGA/ER Crane No. 144015/Rajkot/WR Crane No. 144011/NBQ/NFR Crane No. 144008/Miraj/CR Crane No. 144001/VSKP/ECoR Crane No. 142269/NJP/NFR Crane No. 142265/RTM/WR Crane No. 143009/BKSC/SER Crane No. 142266/GONDA/NER Crane No. 143003/SEE/ECR Crane No. 144021/GONDIA/SECR Crane No. 142041/BIA/SECR Crane No. 144012/PURNA/SCR Crane No. 144003/AJNI/CR 24 items. 51 items NOT SUBMITTED 81 items 33 items 03 items 27 items opined it will follow JMP recommendations. opined it will follow JMP recommendations. 37 items 56 items NOT SUBMITTED 08 items NOT SUBMITTED 29 items 34 items 19 items NOT SUBMITTED 173 items NOT SUBMITTED 124 items 179 items NOT SUBMITTED NOT SUBMITTED DISCUSSION a) List of spares for regular use to be purchased/ stocked at depot level (Cat-C- 76 items) circulated earlier were re-circulated. Few users have made noticeable procurement/stocking of some minor spares. b) JMP proposed to add 09 more items (Belts etc.) in this category for consignees. Some users suggested adding more materials in ‘C’ category list to be kept at Consignee end. This should include: Small bearings, Seal kits, Nylon items, Hoses at zonal basis, Electrical items, Gauges and sensors. CWM/JMP’s comments: This extended list of ‘C’ category items to be prepared by JMP within very short period. c) Action taken by JMPW after the meeting: Previous list of 76 items reviewed. List of 161 C-category items (attached) prepared on 26-09-11. 73 out of 161 reviewed C-category items are included in reviewed RC list of 788 items. 2.4 Users Requirement of Spares (Item-3, decision-2 of RDSO-MOM) In LKO meeting, some users pointed out that they do not get ALL spares from JMP. JMPW supplies spares against extra purchase made through Estimates. During last 3 yrs, 16 zones approached us for spares & all received part/ full compliance depending upon availability. Feedback received from users almost confirm this, though some records/data vary. Railway Board’s comments on spares: There is no compromise with spares non-availability at accident spot and crane item could not be procured in open market basis. Users should submit vetted indents to JMP so that procurement action can be taken in advance. DECISION TAKEN: (a)Future requirements should be met through RC as done by Parel. This has been discussed in para 2.1, 2.2 & 2.3 above. (b)Material Released from MLR: Presently JMP has 61 types of released parts which even after completion of 8, 15 or 19 years of service are still workable. Interested crane users may see the list in Crane Cell/JMP and submit demands for these which may be given free of cost. In case of no demand, these may be scrapped after six months. Page 6 of 14 2.5 Schedule Maintenance (Item-7 & item 9-(5&6) of RDSO-MOM) DISCUSSION a) Even decades old users have not yet arranged hydraulic torque wrench required in 04 yearly schedules in spite of collection of procurement details from JMP by many. Hydraulic torque wrench to be procured by all crane users (old & new design) for the 04 yearly schedules to test the specified torque of slewing ring fasteners (studs & nuts). Soft copy and hard copy of detail specification and cost details has been distributed among participants. b) CMPE/NER advised that this procurement may be done by JMPW against their zone wise vetted indents. This was agreed to. c) Data collected by SEG teams for 28 cranes show that many users do not follow maintenance schedules even partly. Some examples are: 1. 2. 3. 4. 5. 6. Crane No. 144002/Agra/NCR Crane No. 142270/CNBE/NCR Crane No. 143005/Roja/NR Crane No. 144011/NBQ/NFR Crane No. 143010/DNR/ECR Crane No. 142267/BRWD/ECR For remaining cranes too, the statistics (22% users not maintaining even partly) expected to be same. Many users conduct Schedules partly. Conclusion: All agreed that schedules are required to be done. Some users complained about shortage of staff whereas some complained about lack of infrastructure. DECISION TAKEN: DME (P)-II/R.B. distributed the authority letter regarding staff requirements and instructed users to keep the desired strength of crane staff. Regarding infrastructure, DME (P)-II/R.B. repeated the instructions given earlier during meeting at RDSO and stated that failure in achieving the targets will be viewed seriously by Board. It was agreed that procurement of hydraulic torque wrench may be done by JMPW against zone wise vetted indents. 2.5 Life extension beyond 26 yrs.( Item-5 of RDSO-MOM) (a) Schedule suggested by Parel mentioned below : 1st POH of a crane………….8th year 2nd POH of a crane………….14th year Rehab of a crane………….20th year 3rd POH of a crane………….28th year Condemn of a crane………….36th year DME (P)-II reiterated that condemnation of the crane is not to be planned on age basis. (b) For cranes which have already undergone MLR in 14 th year, second Rehab level attention shall be required in 28th year after structural audit by RDSO (Item-5,decision-1 of RDSOMOM) in 26th year. (c) For cranes which have not undergone MLR, the 2 nd POH (14th year )will have to be conducted with complete overhauling of Hyd Pumps, Hyd Motors & G/boxes for which B/Q no.AGRO/JMP/Repair dt 31-8-11 has been collected from M/s Agromach. This was not required in 1st POH (8th year) as per earlier classroom instruction by Gottwald. (d) The consequent excess POH/MLR arising (19 nos in 2012-13 and 12 nos in 2013-14) for JMPW is very high. During RDSO meeting, CWE/ER had suggested sharing of this load with Parel (which has much lesser load of cranes) to liquidate overdues—Item 5&6 of RDSOMOM. DME(P)-II clarified that Gottwald design crane related work will be handled completely by JMP only. Page 7 of 14 2.6 Defect/failure reporting to JMP Points discussed were as follows: • JMP receives AVERAGE 60 to 74 reports for 52 cranes in 12 months. This amounts to 1.25 visits per crane per year though 35 cranes are indigenous. For Parel this figure is higher in spite of ALL cranes being imported. • Users had been asked to deposit details of on-site & off-site failures. Summary of report received is given below: 1. Crane No. 144010 / KURLA/CR On site – 0 Off site -0 2. Crane No. 143004/SBG/ER On site – 0 Off site -1 3. Crane No. 144020 /ERS/SR On site – 0 Off site -1 4. Crane No. 143006/KBJ/ECoR On site – 1 Off site -3. 5. Crane No. 144006/TNP/SR On site – 0 Off site -11 6. Crane No. 144019/TPJ/SR On site – 0 Off site -0. 7. Crane No. 143010/DNR/ECR On site – 3 Off site -14 8. Crane No. 144005/SBP/ECoR On site – 0 Off site -5 9. Crane No. 142033/MGS/ECR On site – 1 Off site -2. 10. Crane No. 142042/TSK/NFR On site – 1 Off site -4 11. Crane No. 143002/GHY/NFR On site – 0 Off site -2 12. Crane No. 142032/BSP/SECR On site – 0 Off site -0 13. Crane No. 142271/DLI/NR On site – 0 Off site -0 14. Crane No. 142270/CNB/NCR On site – 1 Off site -7 15. Crane No. 142038/LKO/NR On site – 1 Off site -1 16. Crane No. 142037/HWH/ER On site – 0 Off site -29. 17. Crane No. 144007/RPH/ER On site – 0 Off site -3. 18. Crane No. 142039/ASN/ER On site – 1 Off site -6 19. Crane No. 143007/BGA/ER On site – 2 Off site -5 20. Crane No. 144015/Rajkot/WR On site – 0 Off site -14 21. Crane No. 144011/NBQ/NFR On site – 1 Off site -1 22. Crane No. 144008/Miraj/CR On site – 0 Off site -0 23. Crane No. 144001/VSKP/ECoR On site – 1 Off site -10 24. Crane No. 142269/NJP/NFR On site – 1 Off site -1 25. Crane No. 142265/RTM/WR On site – 0 Off site -0 26. Crane No. 143009/BKSC/SER On site – 0 Off site -4 27. Crane No. 142266/GONDA/NER On site – 2 Off site -21 28. Crane No. 143003/SEE/ECR On site – 0 Off site -1 29. Crane No. 144021/GONDIA/SECR On site – 1 Off site -1 30. Crane No. 142041/BIA/SECR On site – 3 Off site -1 31. Crane No. 144012/PURNA/SCR On site – 0 Off site -8 32. Crane No. 144003/AJNI/CR On site – 6 Off site -24 Conclusion: Checking the reports of 2008-09 (13 users), 2009-10 (18 users) , 2010-11 (31 users) & current year (10 users till now), it is found that some users are more efficient in “Do’s & Dont’s “and “Trouble shooting” where as some users are extremely slack. DME (P)-II stated that few cranes have very high Page 8 of 14 rate of failures, which is not acceptable and suitable action should be taken by ZRs to improve. He also emphasized that preventive maintenance schedules must not be compromised with. Action taken by JMPW (Item-1, decision-6 of RDSO-MOM): CD containing pictorial Do’s & Dont’s distributed to participants. Users advised to log complaints on web/portal with defect code. The Do’s and Don’t’s should be fixed to the crane structure at appropriate places by all users. 2.7 Divisional Core Team for 140T crane (Item-9-(5&6) of RDSO-MOM) Points discussed were as follows: a) 16 nos staff are called for trg prior to handing over a crane. b) 16 Nos. of divisional staff for crane operation & maintenance needs to be ear marked by all users. This instruction is violated by many users. c) For each crane JMPW has trained sufficient no. of staff , but not all of them remain attached to the crane. d) It has been reported that Moradabad crane No.143005 in-charge is an MCM. Crane in charges should be SSE/Grade supervisors. e) Two other cranes (No.143010-DNR) & (No.143001-DHN) are having JE as crane incharges as per jointly signed SEG reports.SSE to be made i/c. f) Crew details submitted by participants is tabulated below: A B C D E F Crane No. & Consignee Crew Details 144010 KURLA/CR 09 Trained 03 Untrained 143004 SBG/ER 12 Trained 144020 ERS/SR 29 Trained 143006 KBJ/ECoR 16 Trained. 144006 TNP/SR 06 Trained 04 Untrained 144019 TPJ/SR 07 Trained 19 Trained Crane No. & Consignee Crew Details 143010 DNR/ECR 09 Trained 05 Untrained 144005 SBP/ECoR 09 Trained 06 Untrained 142033 MGS/ECR 07 Trained 09 Untrained 142042 TSK/NFR 04 Trained 17 Untrained 143002 GHY/NFR 05 trained 01 Untrained 142032 BSP/SECR 08 Trained 01 Untrained Crane No. & Consignee Crew Details 142271 DLI/NR Not submitted. 142270 CNB/NCR 08 Trained 05 Untrained 142038 LKO/NR 17 Trained 142037 HWH/ER 13 Trained 01 Untrained 144007 RPH/ER 10 Trained 07 Untrained 142039 ASN/ER 14 Trained 05 Untrained Crane No. & Consignee Crew Details 143007 BGA/ER 13 Trained 06 Untrained 144015 144011 144008 Rajkot/WR NBQ/NFR Miraj/CR 07 Trained 06 Trained 08 Trained 12 Untrained 10 Untrained 144001 VSKP/ECoR 08 Trained 05 Untrained 142269 NJP/NFR 08 Trained Crane No. & Consignee 142265 RTM/WR Crew Details 04 Trained 13 Trained 06 untrained Crane No. & Consignee Crew Details 144012 144003 PURNA/SCR AJNI/CR 21 Trained 05 Trained 06 Untrained 143009 BKSC/SER 142266 GONDA/NER 143003 SEE/ECR 09 Trained 06 Untrained 09 Trained 144021 GONDIA/SE CR 09 Trained 142041 BIA/SECR 10 Trained Page 9 of 14 Summary: Users (among above 32) having < 1/3rd trained staff= 12.5% Users (among above 32) having < 50% trained staff= 28.1% Users (among above 32) having 50% trained staff= 15.6% Users (among above 32) having > 2/3rd trained staff= 18.7% CONCLUSION: Staff who receive training should be kept attached to the crane. No. of staff trained by JMP for Kurla27, TNP-21, TPJ-18, DNR-15, KBJ&SBP-39, RAJKOT-15, AJNI-20, GHY-16, MGS-33 nos. But the actual attachment is less. DME(P)-II asked ZRs to give confirmation on deployment of staff as already recorded in RDSO minutes. DECISION TAKEN: Participating officers agreed to have competent core team. 2.8 Infrastructure development ( for proper maintenance ) by users: (Item-7 of RDSO-MOM) Points discussed were as follows: a) Users have to develop their infrastructure as per RDSO and to keep the crane properly. instructions for better maintenance b) Existing 52 crane users have not developed required infrastructure as per RDSO recommendations. A.M.(P.U.) has advised in LKO meeting that users to create facilities / infrastructure by 31.03.12. As per reports submitted by 32 out of 52 users, only some have developed these partially. A B C D Crane No. & Consignee Details of Infrastructure available at Crane base 144010 KURLA/CR Not as per RDSO instruction. 143004 SBG/ER Not as per RDSO instruction . 144020 ERS/SR Estimate under preparation sanction Amount Rs.1.5 crore Crane No. & Consignee 143010 DNR/ECR Details of Infrastructure available at Crane base Not as per RDSO instruction. Estimate is under process. Not as per RDSO instruction. Crane No. & Consignee Details of Infrastructure available at Crane base 142271 DLI/NR NIL 142270 CNB/NCR At present NIL, under proposal stage. Crane No. & Consignee 143007 BGA/ER 144015 Rajkot/WR 144011 NBQ/NFR Details of Infrastructure available at Crane base Not available, but sanctioned inGM's Lumsum 2011-12. Not as per RDSO instruction Not as per RDSO instruction 144005 SBP/ECoR 142033 MGS/ECR Under proposal stage. 142038 LKO/NR Not available, crane is attached with Diesel Shed/AMV/LKO. 143006 KBJ/ECoR NIL 144006 TNP/SR Not as per RDSO instruction. 144019 TPJ/SR Under develop ment. 142042 TSK/NFR 143002 GHY/NFR Not as per RDSO instruction. 50% as per RDSO instruction. 142032 BSP/SE CR Not as per RDSO instructio n. 142037 HWH/ER Not as per RDSO instruction. 144007 RPH/ER Not as per RDSO instruction. 144008 Miraj/CR Not as per RDSO guide line but under process 144001 VSKP/ECoR Not Submitted 142039 ASN/ER 50% as per RDSO instructio n. 142269 NJP/N FR Not as per RDSO instruct ion Page 10 of 14 E Crane No. & Consignee 142265 RTM/WR Details of Infrastructure available at Crane base 50% as per RDSO instruction. Crane No. & Consignee F Details of Infrastructure available at Crane base 144012 PURNA/ SCR Under progress, likely to be completed by 30th Nov 2011. 143009 BKSC/SE R Infrastruct ure work under progress. 142266 GONDA/NER 143003 SEE/ECR Under process. NIL 144021 GONDIA/SE CR Not as per RDSO instruction 144003 AJNI/CR Under progress. 11.01.95 30.7.2000 Props subsided due to inadequate packing on poor soil condition. i. Training of consignees being done from time to time. ii. Training Manual for 140T Crane has been prepared and distributed to all consignees. iii. Trouble shooting guide and Do's & Don'ts have been prepared for 140T Crane users. i. Training of consignees being done from time to time. ii. Training Manual for 140T Crane has been prepared and distributed to all consignees. iii. Trouble shooting guide and Do's & Don'ts have been prepared for 140T Crane users. 27.7.04 Sr.DME/BIA Sr. DME/ Abu Road Sr. DME/ Jodhpur Sr.DME/ GHY 1994-95 1995-96 The accident occurred as the soil below the propping subsided due to heavy rain during operation. Action taken by Jamalpur Welding Joint failure of mechanical lock plate between Rear section & super Structure during taking CWT at 5.5m radius. i) A design improvement of switching over to single piece mechanical lock plate done which was accepted by M/s Gottwald. It is being followed in all cranes. 16.11.05 143003 (Sonpur) Reason of Toppling Crane toppled during practice session at ART yard/JU by Jodhpur staff. Operation failure- angle of slew & Jib radius was over looked by the operator. i. Training of consignees being done from time to time. ii. Training Manual for 140T Crane has been prepared and distributed to all consignees. iii. Trouble shooting guide and Do's & Don'ts have been prepared for 140T Crane users. 01.7.06 5 144009 Jodhpur Sr. DME/ Sonpur 4 144002 (Abu Road) 2004-05 3 2005-06 2 143002 1st based at NJP & at present (NGC) 2000-01 142041 (Bhilai) Date of Accident Crane No. Consignee S N Year of MFG 2.9 DECISION TAKEN: DME (P)-II/R.B. repeated the instructions given earlier during meeting at RDSO. Toppling Cases of 140T Gottwald( Vendor Issues,Item5 of RDSO-MOM) 1 142041 BIA/SEC R 50% as per RDSO instructio n. Soil condition poor, 02 Nos. props of same side subsided completely due to poor soil condition and crane toppled. i. Training of consignees being done from time to time. ii. Training Manual for 140T Crane has been prepared and distributed to all consignees. iii. Trouble shooting guide and Do's & Don'ts have been prepared for 140T Crane users. Page 11 of 14 20.5.06 1985-86 Sr.DME/Bilaspur Sr. DME /SBP 20.9.06 08.09.10 144020 (TVC) Sr.DME/TVC/SR 8 143006 (Kantab aji) 2002-03 7 142032 (Bilaspu r) 2010-11 6 The lifting load was under estimated than the actual load. As per estimation of under load the working parameters like CWT combination, propping, slewing angle and jib radius were wrongly used, thus the crane toppled. Proper propping was not done as per soil condition. During practice session at consignee end i.e TVC/SR, the crane was slewed free on rail with full CWT and SLI manual selection of full prop condition, therefore SLI allowed the most unstable situation meants full CWT in back, No load on hook & rotated more than 300 and toppled the crane. i. Training of consignees being done from time to time. ii. Training Manual for 140T Crane has been prepared and distributed to all consignees. iii. Trouble shooting guide and Do's & Don'ts have been prepared for 140T Crane users. i. Training of consignees being done from time to time. ii. Training Manual for 140T Crane has been prepared and distributed to all consignees. iii. Trouble shooting guide and Do's & Don'ts have been prepared for 140T Crane users. i. Training of consignees being done from time to time. ii. Training Manual for 140T Crane has been prepared and distributed to all consignees. iii. Trouble shooting guide and Do's & Don'ts have been prepared for 140T Crane users. Cases of toppling have to be treated as a major accident and corrective as well as preventive action taken immediately. 3.0 Portal & Net connectivity (Item-1 decision-1&3 of RDSO-MOM) DISCUSSIONS: (a) Soft copy & hard copy of ALL manuals prepared by JMP are already available with ALL users. Less use is made of it. Hence ER has launched Portal containing all manuals, Part list, Specifications etc along with format for submission of complaints which can be accessed by all users / RDSO/RB. Complaints shall be received through this mode only. JMP will update relevant sections of manual where change / up gradation of design has taken place. (b) CWM/JMP held detailed discussion on Portal & Net connectivity and demonstrated how to operate the same. Consignee should use the website to fill the complaints & suggestions on regular basis to optimize the benefit of website. Website address: (i) http://www.140t.weebly.com (ii) http://www.sites.google.com/site/140tjamalpurcrane may be followed. (c ) CMPR/NER suggested that part- list on site be provided with additional columns specifying whether that part is RC item , Non-RC item, Emergency Spare or Depot level spare. This needs to be done in due course. (d) Users have not submitted data on crane usage to workshops / Board as required by RDSO minutes. A format for the same has been made on JMP portal now and data should be fed in without fail. 3.1 TRAINING: A) On an average, JMPW has been conducting five courses per year at JMPW , for each and every user, since last 21 years. JMPW has trained about 800+ staff during this period, many of whom have superannuated. After training, all the trained staff have not been essentially attached to their crane, resulting in wastage of some part of training effort. Few participating SSE’s pointed out that they have only 3 to 5 staff as regular attachment for their crane. For every crane user of 05 nos lot, training is being conducted at present. Page 12 of 14 B) Training for developing NEW Crane Drivers: (Item-9, decision- 3 & 4 of RDSO-MOM) JMPW proposes that new staff sufficiently(Std IX or X) literate , should first be given two weeks theoretical training at JMPW & then attached for some time to crane nearest to his division after which the divisional officer would issue competency certificate. JMPW has notified on www.140t.weebly.com website the date of commencement of training, which is planned for Oct”11. DME(P)-II stated that a comprehensive long terms training plan has to be developed joitly by JMP and Parel. Guideline may be taken from Loco Pilot training. C) Request to NFR & Rly. Bd. Firstly a Theoretical Training & then some more Hands-On Training during Load-Test is essential prior to taking over a crane by any new consignee. In spite of being called for Theoretical Training in May’11 for 1 st crane allotted to Lumding, trainees were not deputed. Hence Lumding is presently not in a position to collect this crane likely to be ready soon& next training is scheduled in Oct’11. Lumding should attend this training. If agreed to by Railway Board, Samastipur (already trained for 2 nd crane) may take the 1st crane. DME (P-II) stated that if zones sends formal requests, it could be done. CWM/JMP stated this requires Railway Board approval. D) Specific training in Hydraulics is provided by M/s Rexroth at their premises at Ahmedabad, for which they publish a Jan-Dec Calendar. The Crane Hydraulics Course No.SP11 scheduled for 14 Sep’11 this year, at a cost of Rs.4500/- plus taxes & cess per candidate. Users interested in such course can avail it in next Jan-Dec Calendar year ie; 2012. E) (Item-4, decision-2 of RDSO-MOM) M/s Mechanica Systems was asked to give a date for training of Motherboard & Cards of SLI at Pune. M/s Mechanica Systems replied that it would propose a date after November end. On receipt of programme, users shall be intimated to depute in phases their electrical maintenance man. 3.2 Must change items under POH/MLR ( Item-4, decision-2 of RDSO-MOM) Majority participants left the decision on JMPW. The list of must change items in existing manuals for MLR & POH is optimal which is 100% re-wiring in MLR and condition basis rewiring in POH. 3.3 POH manuals ( Item 8 of RDSO-MOM) Copies of manuals (12 nos) sent to Bd. on 06-8-11. Further up gradation in terms of para 2.5 (c) above shall be done on time. CD containing pictorial Do’s & Dont’s also distributed to participants. 3.4 Users (Sr. DME/DME/ADME/SSE) comments during Conference: a) Sr.DME/DHN raised the issue of nylon packing. It was appraised by Trichy that these are slipping at site. It was informed that two orders have been placed by COFMOW. Users to send feedback to RDSO & JMP. However, if required wooden packing can be procured. Most of the users pointed out that wooden packing are better. b) Sr.DME/ALD has raised question about purchase of Wire Ropes. Presently the only approved source is Non-Indigenous, as both indigenous sources have been demoted to Developmental Status sometime back. SSE/NGP, SSE/ASN, SSE/TPJ & SSE/GKP suggested that M/s Usha Martin Make was OK whereas Sr.DME/HWH & Sr.DME/DHN stated that M/s Bharat Wire Rope Make was OK. c) Sr.DME/CNB pointed out side bearer problem/cracking in his Crane and asked for assistance in repair. On his request team was sent to run out the bogie so that welding could be done. d) Sr.DME/DHN & DME/ASN suggested for the provision of SLI System sensibility of U/C system for propping (horizontality of the crane).Discussed at para 1.2 above. e) AME/MLDT advised adaptation of CBC coupling in place of hook coupling. RDSO to advise regarding this. f) AME/BIA showed photographs regarding infrastructure development of crane. Other users to take inputs from the same. Page 13 of 14 g) The testing period of Wire Rope and Chain Slings specified in RDSO report No.727/90 for old design crane is different from regular “Yearly” practice followed for slings of EOT cranes in Workshops. Sr.DME/P/HWH desired clarification on this account. RDSO to compare and revise the RDSO reports if required. h) Problem after POH: (i) SDAH, MB, KBJ and majority others - No complaints. (ii) Bhilai reported complaints regarding off POH engine, which was discussed with Cummins representative from Kolkata Region. i) Problem after Mfg: TPJ reported excessive positive variation in load reading in case of new SLI (Make- Mechanica Systems) fitted in new crane. This point has been discussed in para 1.2 (f) above. Manufacturer and JMP to check and revert back. j) Dy.CME/Crane/JMP requested that crane users, who are more than 04 years old, should call for assistance from JMP only for major b/downs and not for minor trouble shooting or maintenance. Other items: (i) (ii) (iii) (iv) Gear box overhaul – as discussed in RDSO: system followed by JMP was reviewed and all users agreed that present system is OK. Users pointed out that brake system does not work on single pipe. JMP to check and take corrective action. M/s Agromech have not provided list of spares with cost to JMP, which was to be provided by 15-Aug-2011. M/s P S Engg have not provided list of defects noticed in off-POH cranes to JMP, which was to be provided by 15-Aug-2011 Dy CME (Crane) No. F/CR/140T/39 Jamalpur dt. 26/9/2011 Distribution: 1) The three websites 2) CWE/ER/KKK 3) DME (P-II)/Rly. Board 4) Director/ MP/RDSO Page 14 of 14