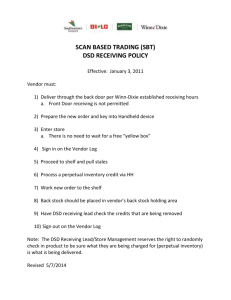

Job Responsibilities

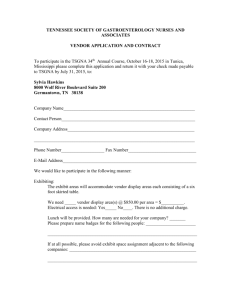

advertisement

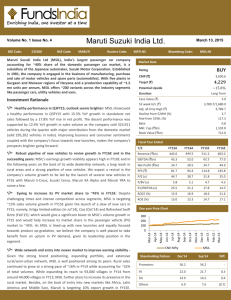

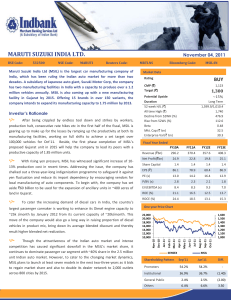

Profile Summary Mobile: Email: VIMAL KUMAR SETHI 09310954124 vksethi19601997@gmail.com Profile Summary Engineer by qualification having more than 29 years experience in supply chain ,Quality & Systems with finest passenger car, two wheelers and automotive part manufacturing companies known for system, procedures, product quality. Started carrier with M/s Escorts limited (Motor Cycle & Scooter Division) in 1981. My association with them was for about three years. During my tenure in Escorts I have worked in QA & receipt Inspection and have also worked for localisation of Yamaha 350 cc Gear & transmission. Work with Maruti Suzuki India Ltd for 20 years. Worked in Vendor development & supply chain for 18 years. Associated with MSIL in 1984 when it was high time for localisation of parts from local vendors by providing the technical inputs to meet the dead lines of localisation. During my tenure in vendor development / supply chain, worked in various departments and dealt with the localisation of various technologies such as Sheet metal & fabrication, Machining parts, Electrical & EMS, forging items, Engine mountings etc The major components under my previews were i.e. window regulators, Door latches, Steering locks, Instrument clusters Engine mounting, electrical assemblies i.e. Alternator Starters, wiper motors, horns & ECU, AC system. The assemblies / parts are not only localised before target time but achieved huge savings. Also CFT member for introducing DI & E nagare system with suppliers which leads to reduction in inventory & space saving at MSIL. Got the training from SMC team for promoting VA/ VE activities at all level at MSIL & vendor end and achieve cost reductions. Also team member of costing cell for standardisation of costing of parts. Team leader for vendor up gradation cell for improving upon systems and procedures at vendor end to achieve zero defects at MSIL and field. Worked in Engineering, PQCI & QA department at Maruti Suzuki for almost two years and worked upon as a team leader for improvement in the customer satisfaction level by improving upon the product quality by systematic joint analysis of field/ line problems along with suppliers at MSIL and ensure timely implementation of counter measures. The claim ratio of high field failures of critical assemblies such as AC system, Alternator, starters, Engine cooling fan & relays, window Regulators, Door Latches, brought down considerably. Good Knowledge about the sheet metal, Forging & machining, Secondary surface treatments operations such as Plating, Powder coating, Heat treatment & Quality systems. From last 7 years working with automotive component manufacturing companies who are tier one supplier to major OEMs such as MSIL, GM, Fiat, Yamaha India, Hero Honda, Mahindra & Mahindra, Ashok Leyland etc and looking after plant operations The Marketing, Purchase and quality & Quality system is directly under my preview. Successfully added new business of MSIL new models such as YP8, YL 9, YC5, YV 4 Model etc as a Single source and also new customers added in customer list i.e. VW, Fiat, and Renault Nissan & Mahindra 2 Wheelers etc. Having sound knowledge about the processes and system to achieve zero defects. Instrumental in increasing the productivity of horn from 1.5 lakhs horns to 4.5 lakhs horns / month with minimum addition of man power and machines. Iam Key person for interacting with Japanese & European collaborators for technical & commercial discussions. Page 1 of 5 Details of company wise work experience. March 09 to Till date :-(Working with leading tier 1 supplier to OEMs ) Company Brief M/s Nikko Auto Ltd is TS 16949 certified company having a technical tie up with M/s Nikko Corporation – Japan and is a supplier of Horn Assembles to OEMs Such as Maruti Udyog Ltd, GM, Hero Honda, Yamaha, New Holland, Ashok Leyland, TVS, Class etc, where as Alpha toyo is manufacturing Inside view Mirrors, Outside view mirrors, Side turn signals, Sheet metal critical assemblies i.e Hand Brake assemblies to Fiat & VW etc. M/s Alpha Toyo is having Technical tie up with M/s SCM – Italy for Parking Brakes.M/s Nikko Auto & Alpha Toyo are having the manufacturing facilities such as press shop with batteries of pneumatic / power presses ranges from 30 T to 300T nos, Moulding machines , beside state of art PLC controlled powder coating facilities, Mirror plant and assembly &Testing Labs. Alpha Toyo Ltd & Nikko Auto Ltd are group companies of M/s Unitech machines with annual group turn over of Rs 1200 crores for FY 2009 -10. Job Responsibilities:Associated with M/s Nikko Auto & Alpha toyo as a Plant Manager for both the companies. The Marketing, supply chain, product quality & Quality systems, are directly coming under me. The Interaction with customer, Price discussions with customers, price finalizations for BOP parts, Conduct annual price negotiation discussion, promote VA/VE activities in plants are the part of my responsibility. Also Monitoring plant efficiencies shop wise, Chairperson along with Executive director to conduct the MRM. Achievements: Increase the productivity of horn from 1.5 Lakhs /month to 4.0 Lakh horns by carrying out certain modification in plant layout & addition of only few basic machines. New Development for Maruti, Hero Honda, TVSM and Yamaha done well before the set time line. New Customer added in the list i.e. VW, Fiat, and Mahindra & Mahindra etc. BOP parts rejection level was brought down from 975 PPM to 125 PPM by upgrading the vendors Scheduling system improved to avoid shortages. New vendor rating system introduced for monitoring vendor performance. Bin system introduced from supplier to improve upon the inventory level & 5-S in store & saving in manpower for disposing the corrugated boxes. Reduction in inventory cost. Reduction in in-house rejection by carrying out daily Red bin activities all around the plant and timely implementation of countermeasures and monitoring of effectively of the countermeasures. Final audit as per revised VW checks sheet is planned in June 2011. Introduce MPS activities in plant for over all improvement in productivity and have been appreciated by MSIL top Management by reduction in mould set up time in moulding shop and improvement in productivity in press shop by introducing the Progressive tools. Resolved the persistent field failure problem existing in horn from last 10 years because of oxidation of local tungsten point by systematic analysis of field failures and appreciated by Hero Honda top Management. Page 2 of 5 Oct 2003 to Feb 2009 worked with Auto components manufacturing company M/s Jenrus Metal/ Soin Steel Pvt Ltd is a supplier of Sheet metal, Tubular and critical Aesthetic items to OEMs Such as Maruti Udyog Ltd, TI Cycles , JBML, Havells India and JCB. .The company was having press shop facilities which include 43 power presses Ranges from 10 T to 600 T, Projection cum spot welding machines, MIG welding sets, TIG welding set , Pipe bending machines , Tube mitring machines , State of art Ni – Cr plating plant, Section rolling machines , Good tool room with conventional machines. Job Responsibilities Associated with M/s Jenrus metal as a Plant Head in Nov 2003. The main responsibilities include to conduct MRM & decide action based upon the shortcoming, making quotations & price finalizations with customers, Conduct annual price negotiation, promote VA/VE activities in plants & at Sub vendor ends, up gradation of vendors by planning regular process & product audits, Monitoring of plant efficiency& plant system & procedures, plant quality and customer complains and systematically closures of NCR. Direct monitoring of the new development to meet customer dead lines. Ensure that customer ratings should be more than 85 %. The Purchase & Marketing Departments are directly comes under me. Achievements: Our team achieved a cost reduction worth of Rs. 42 lakhs thru VA / VE and annual price discussions in spite of increase of Raw material & other input costs. New MSIL Business of YN4, YV 4 & Alto added. Scheduling system modified to avoid shortages on line. New vendor rating system introduced for supplier performances monitoring. Bin system introduced with vendors and 5 S at storage area improved. Inventory level of all category items reduced hence space saving. June 1984 to Sept 2004 ( 19 years 6 months ) M/s Maruti Udyog Ltd – Gurgaon – Haryana Company Profile: - Maruti Udyog Ltd is the largest passenger car Manufacturer in India. Association :- Joined Maruti Udyog in 1984 and worked in Vendor development & Purchase department from June 1984 to July 2000 & involve in Vendor development for import substitute of critical parts from local vendors and also associate with Purchase, Material planning for OE,OE procurements, Inventory Control , Spare parts planning, vendor upgrading, conduct system audits, promote VA/VE activities among vendors, Involve in costing of parts such as sheet metal, machining items, Rubber , Plastic, Electrical components. Also worked for special projects such as reduction in transit damage of vehicles, warranty reduction in critical assemblies like A/C System, Electrical parts & critical sheet metal assemblies’ i.e window Regulators & Door Latches. 1984 (June) to 2000 (July) Engineering & QA :- Worked in Engineering in QA from July 2000 to Oct 2003 and assign special projects by MSIL managements such as reduction in warranty claims of critical assemblies and vendor up gradation. Also worked in Receipt quality for improving upon the parts quality by carrying out the process, product & system audits. My designation at the time of leaving the MSIL was Manager. Page 3 of 5 Responsibilities:1.0 Vendor selection 2.0 Component Development ( Sheet metal, Forging, Machining, A/C Systems, Electrical assemblies ) 3.0 Costing of parts & Price negotiations 4.0 Cost Reductions 5.0 Procurements for OE & spare parts 6.0 Vendor quality improvements & monitoring 7.0 Involve subordinate & vendor for VA/VE activities & guide them 8.0 Conduct annual price meeting with suppliers 9.0 Guide the vendor for system improvements 10.0 Warranty analysis , Decide countermeasure & monitoring of failure or warranty trends of components Achievements 1.0 Regular procurement, planning, scheduling and developments of the components. Approx. 200 components were being procured from 20 vendors worth Rs 450 crores with a team of 4 persons. 2.0 Developed components of new Models like Alto, Wagon R, Baleno, and Versa with in stipulated time. 80 Critical components were developed from 8 Vendors in 9 months. 3.0 Costing of all new components & prices were negotiated with concern vendors. Many components of new models were developed at lower prices as compared to existing model components. 4.0 Old components which were in supply were analysed and re costing done. & prices were re negotiated based on revised castings and cost reductions were achieved. 5.0 Material arranged for all Models by keeping the inventory level very low without effecting the production & quality. 6.0 Packaging standard changed from cartoons to bins & trollies.This helped in avoiding unproductive work like opening & disposing of cartoon boxes. 7.0 Vendor rating of vendors under my preview were improved by improving the systems and procedures at their end. 8.0 Warranty claims of Major assemblies such as A/c systems, Starter, Alternators, Wiper motors, Latch systems, Window winding mechanisms distributor etc. brought down by 50 % by regular joint analysis of market claims and by taking countermeasures at Maruti & at vendor ends. 9.0 Cost saving generated by standardization of items by analysis of functions. 10.0 Achieve annual cost saving on account of VA/VE more than the target set by the company. 11.0 Reduced the transit damage on vehicles during transit by suggesting the countermeasures and achieved the cost savings of more than 4 crores during FY 2002 – 03. Page 4 of 5 1981 to1984 Faridabad - M/s Escorts Ltd. – Motor Cycle & Scooter Division – Company: - Associated with M/s Escorts Ltd in July 1982 & they were the largest manufacturer of motorcycle in India. Responsibilities: - I have been in Escorts for about 3 years, joined Escorts as a Trainee and worked in Standard Room, Receipt Inspection, Quality audits and industrial Engineering department. Job Responsibilities 1.0 Calibrations of Gauges & Jig Fixtures. 2.0 Conduct patrolling inspection at Gear section 3.0 Conduct process improvements 4.0 Analysis of line rejections & decide countermeasures. Achievements:1.0 Introduced shop wise calibration systems. 2.0 Clamping fixture for cylinder for honing was modified from manual to pneumatic which leads to productivity improvement. 3.0 In house rejection for gears line was reduced. PERSONAL DETAILS NAME: - V. K SETHI FATHERS NAME: - Late Sh. Raj Kumar Sethi DATE OF BIRTH: - 24TH July 1960 QUALIFICATION:- BE (Industrial Engineering) from Institution of Industrial Engineering – Mumbai, Diploma in Mechanical Engineering from Board of technical education - Delhi MARTAL STATUS: - Married Expected salary: - Negotiable Computer Literacy: - Fair, Can operate MS Excel, MS words, Power Point Page 5 of 5