Erection Agreement - China power contractor

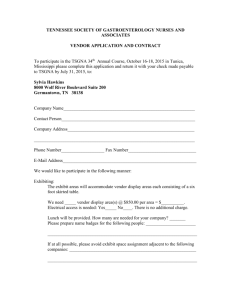

advertisement