doc

advertisement

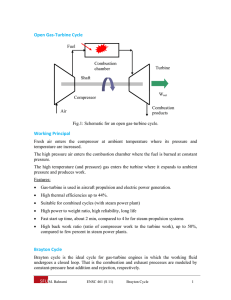

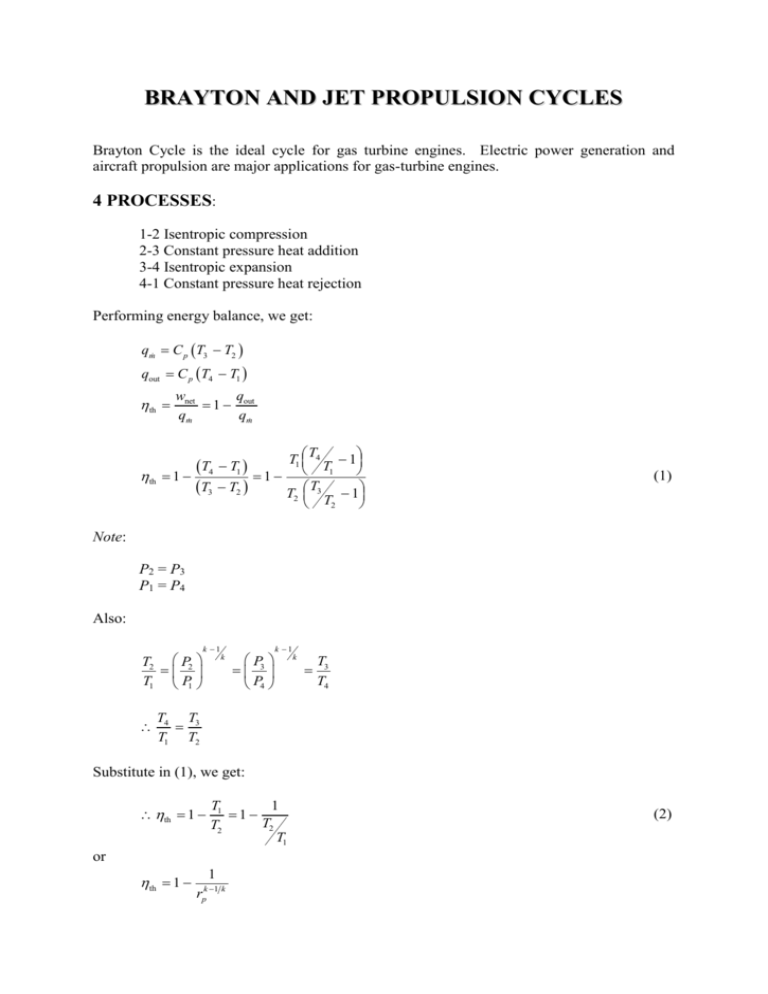

BRAYTON AND JET PROPULSION CYCLES Brayton Cycle is the ideal cycle for gas turbine engines. Electric power generation and aircraft propulsion are major applications for gas-turbine engines. 4 PROCESSES: 1-2 Isentropic compression 2-3 Constant pressure heat addition 3-4 Isentropic expansion 4-1 Constant pressure heat rejection Performing energy balance, we get: qm C p T3 T2 qout C p T4 T1 th wnet q 1 out qm qm T4 T1 1 T T T th 1 4 1 1 1 T T3 T2 T2 3 1 T2 (1) Note: P2 = P3 P1 = P4 Also: T2 P2 T1 P1 k 1 k P 3 P4 k 1 k T3 T4 T4 T3 T1 T2 Substitute in (1), we get: th 1 T1 1 1 T2 T2 T1 th 1 1 or k 1 k p r (2) 2 where the pressure ratio, rp P2 P . 1 DEVELOPMENT OF GAS TURBINES ► Early (1950) gas turbines had simple-cycle efficiencies of about 17% because of low compressor and turbine efficiencies and low inlet temperature of the turbine. ► Effort to improve cycle efficiency concentrated in three areas: (1) Increasing the turbine inlet temperature increased from about 500°C to 1425°C presently. (2) Increasing the efficiencies of compressors and turbines. Efficiencies improved due to designing the components aerodynamically with minimum losses. (3) Adding modifications to the basic cycle, such as regeneration, intercooling, and reheating. ADVANTAGES OF PRESENT GAS TURBINES 1. 2. 3. 4. 5. High efficiencies Lower capital cost Shorter installation time Better emission characteristics Being used for base-load as well as peak load Capacities and Efficiencies Range. Inlet Pressure Capacity Efficiency Temperature Ratio (MW) 540 6.5 2 26 ↓ ↓ ↓ ↓ 1425 135.5 282 39.5 ACTUAL GAS TURBINE CYCLES Actual gas turbine cycles differ from Brayton cycle. In the actual cases: (1) Pressure drops during heat addition and heat rejection processes. (2) The expansion and compression processes in the turbine and compressor, respectively, are not isentropic. The actual processes in the turbine and compressor can be accounted for by the isentropic efficiencies: 3 c ws wa (3) t wa ws (4) BRAYTON CYCLE WITH REGENERATION ■ Heating the high-pressure air leaving the compressor by the hot exhaust gases in a counterflow heat exchanger is known as regeneration (see Figure 8.38). ■ The thermal efficiency of the Brayton cycle increases as a result of decrease in the heat input (thermo-fuel) for the same net power output. ■ Regeneration is used only when the compressor exit temperature is less than the turbine exit temperature. ■ Referring to the T-s diagram, the regenerator effectiveness is given as: qreg, act qreg, max h5 h2 h4 h2 (5) Considering the cold air-standard assumptions, equation (5) reduces to: ■ T5 T2 T4 T2 (6) Assuming cold air-standard assumptions, show that the thermal efficiency of an ideal Brayton cycle with regeneration is given as: k 1 T1 k rp T3 th 1 (7) ■ Comment on the effect of temperature and pressure ratios on the thermal efficiencies. ■ See Example 8.7. BRAYTON CYCLE WITH INTERCOOLING, REHEATING, AND REGENERATION ● Using multistage compression with intercooling reduces the total work of the compressor operating between two pressures. ● Similarly using multistage expansion with reheating increases the workout of a turbine operating between two pressures. 4 ● Even-though intercooling and reheating improves the back work ratio of a gas turbine cycle, but it does guarantee an improvement in the thermal efficiency (why?). ● Intercooling and reheating have to be used in conjunction with regeneration for the thermal efficiency to improve. ● The best performance is achieved when equal pressure ratios are maintained across each stage. For example (considering Figure 8.44) when P P P2 P4 and 6 8 . P1 P3 P7 P9 ● See Example 8.8. IDEAL JET-PROPULSION CYCLES ► Aircrafts are powered by gas turbines that operate on jet-propulsion open cycles. ► In jet-propulsion cycles the gases are expanded in the turbine such that the power produced is just sufficient to drive the compressor and the auxiliary equipment. ► The thrust to propel the aircraft is provided by a nozzle in which high-pressure gases exiting the turbine do expand. ► A schematic of turbojet engine is shown in Figure 8.48. ► Aircrafts are propelled by either slightly accelerating a large mass of fluid (propellerdriven engine) or greatly accelerating a small mass of fluid (turbojet engine) in the opposite direction to motion. ► Gases leave the aircraft at high-velocity after expanding in the nozzle to atmospheric pressure. ► Processes in the diffuser, compressor, turbine, and nozzle are assumed to be isentropic in the ideal turbojet cycle as shown by the T-s diagram (Figure 8.48). ► The net thrust developed by the engine is given by: F m Vexit Vinlet (N) where: Vexit is the exit velocity of exhaust gases relative to aircraft. Vinlet is the air inlet velocity relative to aircraft. ► The propulsive power, Wp is given as: Wp Thrust * Vaircraft (kW). 5 ► The propulsive efficiency, ηp is given by: p Wp Qm . where Q is the thermal energy of the fuel. See Example 8.9. PROBLEM A gas turbine at Dammam Electrical Power Station takes in 108,000 kg/h of filtered outside air at 27°C and compresses it to 6.516 atmospheres. The combustion of gas adds 30 MW of heat to the air. If the turbine exhausts to atmospheric pressure and both the compressor and turbine are 75% efficient: (a) (b) Draw the T-s diagram taking the inlet to the compressor as State 1. Determine the net power output. SOLUTION a) T-s diagram. T s b) Determination of the net power output: Given: T1 27 273 300 K, rp 6 Wnet T c c h2 s h1 c h2 a h1 h 300.19 kJ kg T1 300 K at T1 1 Pr1 1.386 6 Pr2 P2 6.516 Pr1 P1 Pr2 Pr1 * 6.516 1.386 6.516 9.031 Hence T2 s 510 K h2 s 513.32 kJ kg 513.32 300.19 284.17 kJ kg 0.75 h2 a h1 c 300.19 284.17 584.36 kJ kg c Q 30 103 h2 a 584.36 m 30.50 h3 1000 584.36 1584.36 kJ kg qin h3 h2 a h3 qin h2 a T3 1457.3 K, and Pr3 533 Pr4 P4 1 Pr4 Pr3 Pr3 P3 6.516 533 Pr4 81.8 6.516 Hence, h4s = 954.47 kJ/kg t t h3 h4 s t 0.75(1584.36 954.47) 472.42 kJ kg net t c 472.42 284.17 188.25 kJ kg