construction of pvs conduit wiring system of two

advertisement

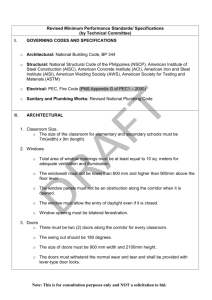

Construction Of PVS Conduit Wiring System Of Two Bedroom Bungalow TABLE OF CONTENT Title Page Litter of Transmittal Release Page Approval Page Dedication Acknowledgement Abstract Preface CHAPTER ONE 1.0 INTRODUCTION 1.1 Types of Conduit System 1.2 Uses and Advantages 1.3 Choice of Conduit 1.4 Materials Used 1.5 I.E.E Regulation CHAPTER TWO 2.0 REVIEW OF COMPOUND UNITS 2.1 Accessories 2.2 Circuit Diagram of Lighting, Ring and Consumer Control Unit. 2.3 Table of Space Factors 2.4 Load Schedule 2.5 Rating Factor CHAPTER THREE 3.0 Construction Procedure 3.1 Conduit Installation 3.2 Conduit Capacity 3.3 Wiring System 3.4 Conduit Wiring 3.5 Building Plan with Design of Electrical Wiring Systems 3.6 Layout Diagram of P.V.C Conduit CHAPTER FOUR 4.0 Operation and Testing 4.1 Verification of Polarity Test 4.2 Insulation Test 4.3 Earthling Test 4.4 Types of Earth Electrode 4.5. Circuit Breaker 4.6 Fuses 4.7 Calculation Under Diversity 4.8 Durability 4.9 Safety 4.9.1 Applications CHAPTER FIVE 5.0 Conclusion 5.1 Recommendation 5.2 Bill of Quantity 5.3 Bibliography CHAPTER ONE 1.0 INTRODUCTION In today’s domestic residence, electricity play a vital function base on how it is used. The institute of electrical engineering (IEE) wiring regulation (15th Edition) defines an electrical installation as an assembly of associated equipment for the fulfillment of specific purpose and having contain coordinated characteristics. Based presented by engineering principle and intelligent conformity to the safety provision of the National Electrical Code. In the application of conductors, switches, insulators, fuses, circuit breakers, consumers control units, lighting fixtures and other related institution component. The design information is presented so as to clearly instruct the installer in constructing the overall electrical installation to achieve the design intent and implement the engineering concept. 1.1 TYPES OF CONDUIT There are different types of conduit namely; Non-metallic conduit Light gauge conduit Heavy gauge conduit Flexible metallic conduit This wall conduit Rigid conduit 1.2 USES AND ADVANTAGES / TYPE 1.1.3 NON-METALLIC CONDUIT:Many types of non-metallic conduit are available, but schedule polyvinyl chloride (PVC) is the one mostly used. It is a regid heavy walled flame – retardant, heat and sunlight – resistant conduit. It may be used in wet on day location in walls, in ceiling and above or below the ground. It is advisable not to substitute PVC irrigation pipe for schedule low PVC conduit. This type of conduit can be use with metal a non-metallic boxes but the non-metallic boxes are not the same as those use with type NPLC cable. 1.3.0 LIGHT GAUGE CONDUIT Light gauge conduit is produced from trip steel which are form into a tube. This type of conduit has an open seam and is only used for small installation at a below 25oc, the light contraction of the tube makes is unsuitable for bending although it can be set. 1.3.1 HEAVY GAUGE CONDUIT There are two types of heavy gauge conduit. Heavy gauge welded conduit and solid draw conduit. Heavy gauge welded conduit is formed from strips of heavy gauge sheet steel and is welded at the seam. This is the most common type of conduit and is supplied in size from 16mm to 32mm. Solid brawn conduit is produced by drawing and heated to over a raw forming a heavy gauge seamless tube. This type of conduit is more expensive than welded steel conduit and is only used for flameproof installation. 1.3.2 FLEXIBLE METALLIC CONDUIT This types of conduit is generally called Greenfield resembles armored cable in appearance but is more adaptable than cable because various sizes and numbers of wire can be pulled into it after it is installed. This type of conduit be used plastic-covered Greenfield when the internal that have a determinative effect on the wire insulation this metal conduit has a thermoplastic outer sheath covering similar to that used on type T wire, the characteristics and uses of which are detailed in. 1.3.3 THIS WALL CONDUIT Electrical Metallic Tubing (EMT), commonly called thin-wall conduit, is a metallic tubing that can be use for expose on concealed electrical installations. Ti use should be contended to dry interior locations because it has a very plating that does not protect it form rusting when exposed to the elements or hurried condition. It is less expensive than regul conduit and much easier to installation, the process of bending require less effort, and the ends do not have to be threaded. In companion to the other wring systems. It ranks behind regid conduit but ahead of the other types of wring when considering the quality and durability of the installation. For this reason and because of the decreased cost in material labour, it is most generally specified for home building construction. 1.3.4 RIGID CONDUIT Black enamel a galvanized regid conduit is approved for used under most conditions and in most locations. Metal conduit and fittings that are protected foam corrosion enamel may only be use indoors and in areas that are not subject to severe corrosion. Although regid conduit is generally the most expensive type of wining, installation, its inherent strength permits installation without running beards and provides additional damage protection. Its capacity facilitates carrying more conductors in one run that in any other system and its rigidity permits installation with fewer supports than the other types of wiring systems. 1.3 CHOICE OF CONDUIT Today PVC is available alternative to other materials for virtually any application. Its combination of advantage make it a preferred choice when a conduit system is needed. Although there are many types of wiring ystem which can be used to provide a safe efficient, imperative and economical installation but in this project we emphasis on P.V.C. conduit wiring system. This when PVC was initially introduced to the electrical field, it was considered a substitute material with limited and special applications for example, because of its PVC design and resistance to corrosion, PVC was found useful in damp, corrosive environments such as chemical and fertilizer plants. As its use by engineers and contractor increased and its system design expanded, PVC’s advantages become evident. Installation of conduit wiring provides mechanical protection and accessible safety to persons and property and provides convenient and accessible electrical raceway system has adequate capacity for future expansion and is readily adaptable to changing conditions. This write-up provides most up to data and comprehensive information about PVC conduit from basic raw material to installation characteristics of the finished product. 1.4 MATERIALS USED Though, there are many types of conduit materials with regard to I.E.E regulation. Therefore, the materials used in this very project have been outlined in details under bills of quantities. The I.E.E regulation strictly explained the actual installation of wring and most of the material used shall be compliance with the appropriate British standard specification provide materials. The following discussion will review the advantage of those standard materials as well as their limitation. Regid conduit has the same size designation as water pipe conduit smaller than ½ inches can only used in finished building where extension are to be made under plaster. In this installation 5/16 inch condition are to be made under plaster. In this installation 5/16 inch conduit or tubing is permitted. The size of conduit is determined by the inside diameter for e.g ½ inch conduit has an inside diameter of approximately ½ inch. Standard conduit has an inside diameter of approximately ½ inch. Standard conduit size used in interior wiring are ½, ¾, 1, ½, 1¼, 2 and 2 ½ large size are available for special use in certain commercial and factor installations. 1.5 I.E.E REGULATION These regulation covers in details the actual installation of wiring and apparatus in the building and requirement that most of the materials used shall comply with the appreciate British standard specification provided materials are tough from times of repute, no difficulty should arise in concention with BSS. Generally the I.E.E. regulation related principle to the design selection, inspection and testing of electrical installation, whether permanent or temporary safety especially from fire, shock, and burns. Hence good workmanship and proper materials shall be used and all equipment shall be suitable fro the maximum power demanded by the current using equipment when it is function in its intended manner. *** INSTRUCTIONS *** Please Read The Below Instructions Carefully. ****************************** HOW TO ORDER THIS COMPLETE MATERIAL If you want to order the complete materials (Chapter One to Five, Including Abstract, References, Questionnaires, Proposal (where applicable)) of the above mentioned topic, please visit www.freeplace.org and click on “Order” (i.e. www.freeplace.org/order) ****************************** HOW TO BECOME OUR PARTNER To become our partner, visit www.freeplace.org and click on partnership. ****************************** TERMS OF USE This Material is for Academic Research Purposes only. On no account should you copy this material word for word. Copying this material “Word for Word” is against our “Terms of Use”. That you ordered this material shows you have agreed Our ‘Terms of Use’. ****************************** Better is not good enough, the best is yet to come! Endeavour to be the best!! 2002.