Relation With Program Outcomes

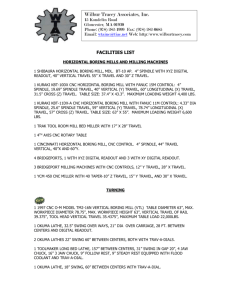

advertisement

MELİKŞAH UNIVERSİTY Faculty of Engineering and Architecture Department of Mechanical Engineering MECH452 APPLICATION OF CAD/CAM II Syllabus Course Type Class/Time Weekly Load (T+P) Credits/ECTS Instructor Office Office Hours Email Course Assistant Email Must course/face to face MMF CNC LAB / Tuesday 08:30-14:15 3+2 2/3 Specialist. Emrah ŞEFKATLIOĞLU MMF 434, Phone: Open policy esefkatlioglu@meliksah.edu.tr SELİM DOĞAN selimdogan@meliksah.edu.tr Course Objectives: This course will introduce you to CNC (Computer Numeric Control) Lathe Machine firstly. Teaching CNC Lathe programing with ISO international codes and CAM (Computer Aided Manufacturing) program. This course will introduce the concepts of CNC machines and programing. Second session is application part. This part include some duty about design 3D models or project and manufacturing of this projects. Students must use CNC Lathe and Milling machines to manufacture this projects. Course Outcames CO1 CO2 CO3 CO4 Ability of programing manuel CNC Lathe Machine. Ability of Operating CNC Lathe Machine. Ability of design an engineering system design. Ability of manufacturing engineering system. Contents Related Program Outcomes 2,3,4 1,3,4 1,2,4 1,2,3 Related Course Outcomes 1. INTRODUCTION TO COURSE(1st weeks) Introduction to Workshop, Worksafety, Lathe Machines and Iso codes CO1 2. INTRODUCTION TO CNC LATHE PROGRAMING (2nd week) CO1 -İntroduction to ISO standart G codes -Program Structure -Program Blocks -Program Format 3. AXES CO-ORDINATE SYSTEM, METHODS OF DIMENSIONING, MACHINE CO-ORDINATE SYSTEMS(3rd week) CO1 -Co-Ordinate Axes -Direction of Movement -Methods of Dimesioning -Absolute System of Dimensioning -Incremental System of Dinesioning -Units Of Dimensioning -Machine Origin Co-Ordinate System -Workpiece Co-Ordinate System -Machine Reference Point Co-Ordinate System 4 PROGRAMMING OF G CODES, TOOL OFFSETS, CUTTER RADIUS COMPENSATION G CODE LIST(4th week) -G00 Rapid Positioning -G01 Linear Interpolation -G02/G03 Circular Interpolation Parameters -G90 Absolute System Of Dimensioning -G91 Incremental System Of Dimensioning -G94 Feed Rate Per Minute -G95 Feed Rate Per Revolution -G96 Constant Surface Speed -Thread Cutting CO2 CO2 5. M-CODE LIST(5th week) -Miscellaneous -Canned Cycles -Direct Dimension Programing 6. DESIGN 3D MODEL FO PROJECTS (7th-8th weeks) -Determine Concept Design -Drawing 3D Models -Calculations -Fulfilling Detail Design 7.MANUFACTURING PROJECTS(9th-10th-11th-12th weeks) -Manufacturing Project parts with CNC 8. WORKSHOP WORKS OF PROJECT(13th weeks) -Thapping -Reaming -Coating -Smoothing e.t.c. 9. ASSEMBLY OF PROJECTS(14th weeks) Resources Textbook Author Publisher Edition Other Resources : Computer Numerical Control Of Machine Tools : Dr.Dimitris Mourtzis : Pearson : (2013) : Computer Numerical Control Programming Basics CO3 CO4 CO4 Evaluation Midterm Exams It is the essential part of this course and this session is very important. Each group include 4 students and they must select a project for design and manufacture it. Contrubution Level: % 40 Midterm exam is held on 8th week. Numbers: 1 Contrubution Level: %20 Final Exam Contrubution Level: %40 Attandence Students must have at least %80 attendance both for lecture and practice hours. 3 late coming considered as 1 absent. Projects Relation With Program Outcomes Meliksah University, Faculty of Engineering and Architecture, Department of Mechanical Enginnering 1 2 3 4 5 6 7 8 Sufficient knowledge of CNC technology.Take some idea about Milling and Lathe machines.Why we use this machine to manufacuturing Ability to prepare G codes for CNC Lathe machines.Obtain enough knowladge about program stracture ,blocks and format. Understand about Machine Co-ordinate system and workpeace Co- ordinate system.Ability to write codes with Absulute and incremantal consept and direction of movemant Ability to write G codes; Rapid Positioning, Linear Interpolation, Circular Interpolation Parameters, Absolute System Of Dimensioning and Incremental System Of Dimensioning Ability to Miscellaneous functions like Canned Cycles and Direct Dimension Programing.Learning Coolant on of spindle commends. Ability to desing an engineering Project for manufacturing.Lerning to consider manufacturing when someting is designed Ability to manufacturing parts with CNC Milling and Lathe machine and learn machining details Ability to assemble parts and compose whole system and learning detail of assembly, tolerances Contribution Level 1 2 3 4 x x x x x x x x 5