Zeiss SMT - CUED (groups) Web server

advertisement

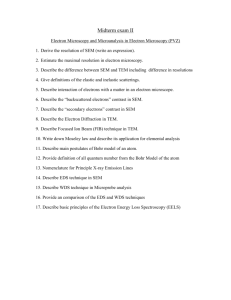

Department of Engineering Proposal for Collaborative Research between Electrical Engineering Division, CU Engineering Department and Zeiss SMT D M Holburn, B C Breton and N H M Caldwell 1. Introduction Zeiss SMT is the major player in the electron microscope market. To maintain and increase market share, Zeiss SMT must continuously enhance their products through innovation in both software and hardware. Innovation requires ongoing research into many aspects of microscopy, which is costly in terms of financial and personnel resources. Collaboration with academia provides a cost-effective mechanism for speculative research and development. This proposal describes a continuing programme of research with Cambridge University Engineering Department (CUED) and Zeiss SMT under the auspices of CAPE, the newly-established Centre for Advanced Photonics and Electronics. CAPE is an exciting new venture based around world-leading facilities and expertise in the Department of Engineering at the University of Cambridge. It builds on Cambridge's history of world-leading research in Photonics and Electronics by significantly enhancing collaboration with industry. Supported and guided by a small number of strategic industrial investors representing the global supply chain in this sector, the Centre will lead to a new form of joint university-industry research that is leading edge, vertically integrated and commercially relevant. CAPE will: emphasise rapid application of breakthrough research by placing issues of industrial importance at the top of the research agenda; provide a focal point for contributing companies to form strategic relationships at an early stage involving directed R&D; and provide a focus for multidisciplinary research involving engineers, but also chemists, physicists, materials scientists and bioscientists. At present there are four strategic partners: Alps Electric Company Limited who contribute expertise in optoelectronic components; Marconi Communications Limited with expertise in systems; Dow Corning Limited who bring materials expertise; Advance Nanotech Inc whose expertise is in nanotechnology research; The CAPE model fully supports the concept of third-party collaborators who sponsor and support research carried out within the CAPE environment. 2. Track Record Researchers at CUED have an impressive record in the research and development of the scanning electron microscopes. Research on the SEM dates back to 1948 and this department has had the distinction of continued research during the intervening period. In the most recent Research Assessment Exercise, the Department achieved the highest possible rating of 5*A (international and national excellence in all areas of research). There has been strong collaboration between the University Engineering Department with Cambridge Instruments and its successors since the time of the first SEMs. These have built strong links at a professional, technical and personal level between staff in both organisations. The most recent collaboration, between LEO and CUED, involving the present team, began in 1998. The research carried out delivered a number of important successes in advancing scanning electron microscopy: 1. Software was developed to interface LEO instruments to the Internet using Web-based technologies, providing new opportunities in remote diagnosis, operation and collaboration. This was developed by Gopal Chand, who, having completed his doctorate in aberration compensation for electron microscopy, joined LEO as a full staff member. With his participation, the CUED software was transferred to LEO and reimplemented as the commercial NetSEM package. 2. An expert system was designed and implemented (as stand-alone & web-based software) [1] to assist service engineers with diagnosing faults on LEO 400 series instruments. Both versions were completed to final prototypes and delivered to LEO. 3. An expert system was developed to enhance ease of use of LEO 400 series instruments. This system (XpertEze) [5, 8, 11] demonstrated that software incorporating expert knowledge on instrument operation can reliably and effectively control the SEM. 4. Research into tungsten filaments produced algorithms and associated software for automated filament saturation (AutoSat) [16] and filament lifetime monitoring. This has found extensive use within the company as a reliable mechanism for gathering consistent data about filament performance. 5. Algorithms for beam profile determination – a research project undertaken by Malavika Chandra, Department of Physics. 6. Computer-based algorithms were developed for gun alignment, focusing, dynamic noise reduction, astigmatism and other applications, with prototype software delivered to LEO. 7. A method based on neural networks was developed for use in particle analysis, of wear debris. The system proved very successful at detecting narrow cracks, with few false positives. [13] The collaboration had a significant impact in academic as well as commercial spheres. It resulted in a considerable number of technical and academic publications, of which key items are listed in section 6. Members of the programme regularly attended highprofile national and international conferences and presented papers. The programme regularly contributed to a variety of locally organised courses for industry, including Computers in Microscopy (RMS), Advanced Image Processing, CAMSEM, 50 years of SEM (Dec ’04). A significant number of Masters’ students have participated actively in the projects listed, as well as a range of related activities. Thanks to the collaboration, some hundreds of undergraduate students and dozens of graduate research students have now had direct experience of using LEO instruments. 3. Research and Development Programme We propose a new collaborative programme to build upon the success of previous collaborations. We identify a number of key areas where advances will deliver technical know-how, tools for internal Zeiss activities, enhancements to existing and future instruments, and potential new products. 3.1 Intelligent Microscopes The XpertEze system [5, 8, 11] represented a “proof of concept” and was targeted at the LEO 440 instrument. We propose to extend its coverage of SEM operation to other instruments in the Zeiss SMT series, and, with cooperation from Zeiss, to provide knowledge bases for use in specific microscopy applications. We would aim to re-implement XpertEze as an embedded system, in a form conveniently callable from languages like VC, VB, for incorporation within the next generation of microscope software. This research will dramatically improve the ease of use of Zeiss SEMs, providing optimal imaging to customers regardless of skill level. 3.2 Service Support Tools for SEM and TEM We propose to assist Zeiss personnel in the deployment and maintenance of service support tools. This could be pursued through development of an on-line searchable database; or alternatively through further development of the First A.I.D. expert system. In addition, we propose software extensions to provide integrated diagnostic assistance for newer Zeiss microscopes (both SEM and TEM), this will yield direct savings in technical support and improved service through better fault diagnosis. 3.3 Improvements in Electron-Optics Control We aim to undertake further research into novel algorithms to control various aspects of SEM electron-optics, including focus, astigmatism, and saturation of lanthanum hexaboride filaments, specifically for the newest Zeiss instruments, and to extend these to encompass different electron sources. The resulting advanced autofunctions will add extra functionality and further improve the ability of Zeiss SEMs to be deployed as fully automated instruments. 3.4 Novel Stereo Techniques and Intelligent Stereo Stereo imaging and stereometry represents a relatively unexploited application of the SEM. In addition to producing visually attractive images guaranteed to catch the eye at exhibitions, stereo imaging can provide specimen depth information which would be valuable in many SEM applications (see 3.6). The drawbacks of the current stereo implementation, namely its limitation to specific column design and difficult user interface, have restricted the uptake of the technique. We propose to develop new stereo techniques that can be used with conventional, variable-pressure and fieldemission instruments, and to design intelligent software ‘wizards’ specific to stereo imaging to eliminate the “black art” nature of stereometry. 3.5 JITS (“Just In Time Scanning”) Microscopy Biological applications frequently require uncoated and fragile samples to be exposed to the hostile environment of the specimen chamber and the electron beam. Despite advances in variable-pressure microscopy and low voltage imaging techniques (courtesy of field-emission instruments), operators still have a limited time-frame to obtain usable results before charging and/or beam damage becomes excessive. We propose to investigate “just-in-time scanning” techniques for instrument operation to reduce the inevitable damage and extend the operator’s window of opportunity. A successful outcome will further improve the usability of Zeiss instruments in the growing medical and bioscience markets. 3.6 Manipulation of Nanoscale Objects in the SEM Nano-assembly and manipulation is becoming an increasingly important tool for characterisation of objects and also in building prototype devices. For example, nanomanipulation can be used to pick up small objects (organic nanowires, cells, laminar slices) and to place them onto electrodes or grids for characterisation. The objective of this proposed project is to demonstrate controlled movement of a nano-object (eg. nanowires, nanospheres, organic objects) from a source location to a target location (eg. electrical electrodes), in the SEM. We propose a system based upon a scanning electron microscope, in which to carry out nanomanipulation and measurement of material characteristics. The SEM is an ideal environment for such a development. The versatile stage driven by user-friendly software, facilitates easy location and inspection of the specimen, and the availability of real-time high-magnification images and electronic signals opens up the possibility of carrying out manipulations on an automated basis. However, the stage is not ideally suited for the specific purpose of controlling the manipulator, which is required to move relative to the substrate. There is often a height difference between the nanomanipulator and the object being picked up. Also, there is a need to calibrate the manipulator movement to the coordinates of the SEM. Hence there is a requirement to develop an accurate 3-D model of the environment (manipulator and target object) in the SEM, which may be used to perform manipulation in an integrated manner, and to identify the location for the manipulator to go, or what to pick up). In order to demonstrate nanomanipulation within the SEM in an integrated fashion, three main areas of research are required: Visualisation of the environment Techniques for building up a 3-D model of the nanomanipulator and the target object will be explored. These will involve use of automatic focusing algorithms and direct stereometry in the SEM to determine the spatial coordinates of the object and target location. Direct dynamic 3D measurements will be made using stereometry or automatic focusing, to determine the time-varying position of the manipulator, and to feed back information about the deformation of the cantilever and its altitude above the substrate. In this way, it will be possible to carry out semi-automatic manipulations and measurements quickly and conveniently. Hardware development A 3-D nanomanipulator will be designed and built using a suitable 3-axis piezo micro-translator system, under computer control, by means of which a manipulator or cantilever can be swept accurately across the surface under controlled conditions. The manipulator may be a silicon-micromachined flat cantilever, etched tungsten tip or even grippers. The nanomanipulator will be integrated into a suitable SEM. Software development The 3-D model will form the basis of the interface to the operator and also manipulation. This interface will be required to communicate with the SEM in order to perform imaging, and also with the micro-translator system for movement. The interface will contain calibration algorithms, and will use visualisation techniques as well as manipulator movements in order to build the 3-D model. The 3-D model may be used by the operator to move and engage objects, and will also facilitate the simulation of complex manipulative or nano-assembly tasks in the model before committing to the tasks themselves. 3.7 Extension of image processing capabilities Several applications proposed above and for the future depend on efficient real time processing of image and other data. With most current instruments a single CPU is responsible for control of the instrument and all other monitoring activities as well as the user interface. We propose to investigate the suitability of multiple-processor PC architectures, allowing time consuming computational tasks (for example, Fourier Transforms, spatial filters, deconvolution, correlation, neural nets) to be devolved to a dedicated processor or processors. This will involve a study of efficient means of sharing data, as well as optimisation of the way tasks are assigned. 4. Other Applications of SEM We have become aware of numerous ways in which the use of SEM has been of immense benefit to groups within the Electrical Division, which is now consolidated on a single site in West Cambridge. It has not hitherto been possible to support more than a few of these activities on the group’s own instrument, which has been fully occupied in research; as a result, researchers have been compelled to compete for use of other instruments elsewhere in the University. Activities in which SEM has played a significant role include: Inspection of carbon fibres Examination of ink/bubble jet print heads and media to establish methods for more efficient dispersal of ink; Quality control of lithographic processing Examination of semiconductor devices (smart power, high voltage) Inspection and operation of micromachined cantilevers, accelerometers and other transducers and assemblies Inspection of optical devices, fibres and couplers Development of methods of lithography based on contamination Quality control for fabrication of carbon nanotube materials and structures. These projects are ongoing, and will be augmented as research at CAPE gathers momentum. There is therefore a urgent requirement for the continued availability of a suitable SEM to support these needs. In addition, there is a strong need for an instrument to help serve the needs of teaching: those courses and modules with a significant requirement are listed, with typical numbers of students involved: 4B7 VLSI Design, Technology and CAD (20) - Practical SEM sessions: approximately 2 hours in groups of 3-5 4B6 3B2 Integrated Digital Electronics (80) – SEM micrographs to indicate IC structures Part IA Linear Circuits and Devices (300) - provision of SEM micrographs to illustrate device structures; Solid State Devices (20) 5. Intellectual Property, Confidentiality and Project Review Work done under the auspices of CAPE is bound by contracts negotiated with Sponsors, pursuant to the Strategic Partnership Agreement (SPA) signed by the University and the Strategic Partners. This protects all parties involved. Negotiations involve the CAPE Steering Committee, as well as the Principal Investigator and the proposed Sponsor. The terms of the Contract govern the way in which IP arising from the Project will be handled. Individual contracts may allow for IP to be licensed, exclusively or non-exclusively, to the Sponsor; or it may be assigned to the Sponsor, typically with a revenue-sharing agreement agreed between the University and the Sponsor. In other instances it may be placed in the public domain. Members of the University are bound through their contracts of employment, as are those employed by the strategic partners. Students working on CAPE projects will be required to sign a confidentiality document. The University is required to provide the Sponsor regular reports on the progress of the project. Typically, these comprise brief written reports at six month intervals and a final written report within three months of the expiry or termination of the project. As it is anticipated that much of the research carried out under the auspices of CAPE may, in due course, result in patentable and commercially exploitable innovations, emphasis is placed on accurate record-keeping, to ensure that the nature and date of any invention made can be established. The CAPE office provides numbered laboratory notebooks for use by research staff. These remain the property of the University. Under this proposal, it is understood that an important benefit for Zeiss SMT would be the opportunity to showcase their premier products in a cutting-edge environment, where they would be used by and exposed to resident and visiting scientists, academics, students and others. This kind of interaction is fully recognised as an integral component of collaboration under the auspices of CAPE. It is expected that CUED personnel would visit Zeiss headquarters on a regular basis for the purposes of review and discussion, and where appropriate, technical assistance. We would also invite Zeiss personnel to visit CUED for collaborative planning sessions and an opportunity to interact with projects. 5. Project Team The Principal Investigator for the project will be Dr David Holburn. Subject to the availability of supporting funding, it is also agreed that Mr Bernie Breton will provide advice and experienced support on a part-time basis, and Dr Nicholas Caldwell will oversee key aspects of software development. Research Students will be sought to undertake parts of the project under CAPE contracts, EPSRC studentships, or other awards, and projects will be offered to fourth-year M.Eng students to develop support tools and conduct ancillary investigations. David M. Holburn is a Senior Lecturer in electronics and integrated circuit design in the Cambridge University Engineering Department and a Fellow of Gonville and Caius College Cambridge. His research interests include automation and remote control of electron microscopes, mixed-signal ASIC design, medical instrumentation, and embedded computing systems for machine vision and other applications. He received an MA and a PhD in engineering from the University of Cambridge. He is a chartered engineer and a member of the Institution of Electrical Engineers. Bernard C. Breton recently retired as a Senior Research Associate in the Cambridge University Engineering Department. He has more than 30 years experience with SEMs including everything from installation to marketing. His research interests include 3D imaging, virtual reality, multimedia, and telemicroscopy. He is a Fellow of the Royal Microscopical Society. It is anticipated that he will contribute on a parttime basis, providing support and guidance through his broad experience of the instrument and its applications. Nicholas H.M. Caldwell is a Research Associate in the Department of Engineering at Cambridge University. His research interests are knowledge-based systems, Internet and multimedia technologies, and electron microscopy. He consults in a freelance capacity in web design and development. He received a BA in computer science and a PhD in engineering from the University of Cambridge. He is a chartered engineer, a full member of the British Computer Society, and a Fellow of the Royal Microscopical Society. 6. List of Publications Full Papers 1. “An Expert System for Fault Diagnosis in the Scanning Electron Microscope”, NHM Caldwell, BC Breton & DM Holburn. Paper presented at the Expert Systems ’96 conference. Full paper in Applications and Innovations in Expert Systems IV, pp 177-188, SGES Publications, 1996. 2. “World Wide Web Controlled Scanning Electron Microscope”, G Chand, BC Breton, NHM Caldwell & DM Holburn. Full length version of (7), published in Scanning: The Journal of Scanning Microscopies, (June 1997), Vol 19, 4, pp292-296. 3. “Remote Microscopy in the Real World”, BC Breton, G Chand, NHM Caldwell & DM Holburn. Microscopy & Analysis, (September 1997), pp19-21. 4. “Towards the Intelligent SEM”, NHM Caldwell, BC Breton & DM Holburn. Paper presented at the EMAG ’97 conference. Full paper in Electron Microscopy and Analysis 1997, (Institute of Physics Conference Series Number 153), pp 53-56, Institute of Physics Publishing, 1997. 5. “XpertEze : A Knowledge-Based Approach to Scanning Electron Microscopy”, NHM Caldwell, BC Breton & DM Holburn. Paper presented at the Expert Systems ’97 conference. Full paper in Applications and Innovations in Expert Systems V, pp 127-140, SGES Publications, 1997. 6. “Remote Instrument Diagnosis on the Internet”, NHM Caldwell, BC Breton & DM Holburn. IEEE Intelligent Systems, June 1998. 7. "NetSEM Collaborator - An Application in Telemicroscopy", Breton, B.C., Chand G., Howard, P.J., Caldwell, N.H.M., & Holburn D.M., in Proceedings: Microscopy and Microanalysis 1999, Vol 5, Supplement 2, 1999, pp 320-321. 8. "WebXpertEze: intelligent instruments via the Internet", Caldwell, N.H.M., Breton, B.C., & Holburn D.M. Presented at 12th European Congress on Microscopy, Brno, Czech Republic. Proceedings of the 12th European Congress on Electron Microscopy, Volume III Instrumentation and Methodology, pp411-412, Czechoslovak Society for Electron Microscopy, Brno, 2000. 9. "Sharpness search algorithms for automatic focusing in the scanning electron microscope", Batten, C.F., Holburn, D.M., Breton, B.C. and Caldwell, N.H.M., in Scanning, Vol. 23 No. 2, March-April 2001. Proceedings of SCANNING 2001, pp 112. 10. "Prolog Knowledge Base Supplies Embedded and Web Remote Control: Intelligence for Microscopes", Caldwell, N.H.M.C., Breton, B.C. and Holburn, D.M.. PC AI, Vol. 15, 3 (May/June 2001) pp 25-26, 28. 11 "ExpertEze: developing embedded intelligence for the scanning electron microscope", Caldwell, N.H.M.C., Breton, B.C. and Holburn, D.M. in Microscopy and Analysis 7 (Supplement 2: Proceedings), pp 966-967, 76, August 2001. 12 "Web-Based Expert Systems: Information Clients versus Knowledge Servers", Caldwell, N.H.M., Breton, B.C., & Holburn, D.M. (2002). In Szczepaniak, Piotr S.; Segovia, Javier; Kacprzyk, Janusz; Zadeh, Lotfi A. (Editors), Intelligent Exploration of the Web, Springer-Verlag, pp 404-419. 13. "Particle Analysis using Neural Networks and Image Processing in the SEM", Caldwell, N.H.M., Breton B.C., Holburn, D.M., & Young, T.C.W., in Microscopy and Microanalysis, Vol. 9, Supplement 2, pp 738-739. 14.. "Advances in Imaging and Electron Physics – Sir Charles Oatley and the Scanning Electron Microscope", Breton, B.C., McMullan, D., & Smith, K.C.A., Volume 133, Elsevier Academic Press, 2004. Concise Papers and Extended Abstracts 15. “World Wide Web Controlled SEM” , G Chand, BC Breton, NHM Caldwell & DM Holburn. Paper presented at the Scanning ’96 conference. Extended abstract in Scanning: The Journal of Scanning Microscopies, (April 1996), Vol 18, 3, pp201-202. 16. “Automated filament saturation in the SEM”, NHM Caldwell, BC Breton & DM Holburn. Paper presented at the Micro ’96 conference. Extended abstract in Proceedings of the Royal Microscopical Society, (1996), Vol 31, (2), pp126. 17. “A Java Powered SEM”, BC Breton, NHM Caldwell & DM Holburn. Paper presented at the 11th European Congress on Microscopy (EUREM ’96). (Proceedings in press) 18. “FIRST A.I.D. : Using Remote Microscopy and Artificial Intelligence for SEM Fault Diagnosis”, NHM Caldwell, BC Breton & DM Holburn. Paper presented at the Scanning ’97 conference. Extended abstract in Scanning: The Journal of Scanning Microscopies, (April 1997), Vol 19, 3, pp204. 18. “Scanning Electron Microscopy for the Next Millennium”, B C Breton. Paper presented at the Scanning Microscopy International 16TH Pfefferkorn Conference Aberystwyth, Wales April 5 - 8 1998. Paper published in special supplement of Scanning Microscopy.