Robert Renick - Senior Mechanical Designer Resume

advertisement

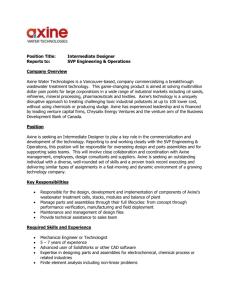

RESUME OF ROBERT E RENICK JR SENIOR MECHANICAL DESIGNER 5516 Reindeer Place, Paso Robles, CA 93446 (805) 239-5713 Home, (714) 474-4811 Cell, E-mail: rrenick239@msn.com OBJECTIVE: Seeking a position in Mechanical, Product, Tool, Manufacturing, Test or Sustaining Design Engineering. SUMMARY OF WORK EXPERIENCE: 36 years Designing Machines, Mechanisms & Components for Medical, Aerospace and Commercial Products. Knowledgeable in bringing “Products to Market” through determining materials, manufacturing methods, post processes and tolerances for components and systems, in consideration of budgeted costs, anticipated quantities, and respective functional design requirements. Familiar with elements of PLM “Product Lifecycle Management” in accordance with ISO 9001:2008, ISO 13485:2003 and AS9100 REV C and various Regulatory & Standards Organizations such as ISO, MIL, DOD, FDA, FAA, NAMA, ADA & UL. Certified in GD&T ANSI Y14.5M-1994. Extensive Experience in Solid Modeling (16 yrs), Detail Design/Checking, PDM& EPDM. Extracting or consuming PMI “Product Manufacturing Information” from 3DMBD “3D-Model Based Definition” system files. Writing SOW’s and coordinating Off-Loaded Engineering Activities utilizing “Global Development Centers”. Additional support activity includes Specification & Design Reviews. Using ERP/MRP systems, creating and entering BOM’s. Writing ECR’s, DCN’s, NCR’s, CAR’s, FAR’s and various MRB Activity. Supporting Design Validation such as writing test plans, conducting tests and fabricating prototypes. Writing QTP’s and overseeing Product Qualification. Developing and maintaining Design/Manufacturing Schedules, Estimates and SOW’s. Writing Policies, Procedures, Proposals, Assembly & Shop Work Instructions. Qualifying Vendors, Manufacturing Liaison, Applications Engineering Support, establishing and maintaining Client Communication and Relationships. SKILLS: Design Software: SolidWorks 2013, Inventor 2010, Mechanical Desktop, AutoCAD, PDM & EPDM Vault (limited CATIA V experience). ERP Software: Oracle, MAS 500, Vista DCD, Syteline, Avante Microsoft Software: Word, Excel, Power Point, Outlook, Project and Visio EDUCATION: Western Washington University in Industrial Arts (101 Credits) Dutchess Community College Continuing Education (12 Credits) Apprenticeship: The Boeing Company, Everett Washington, Aircraft Tool Design. 6 months classroom training and four 3-month working rotations through “Major Airframe Assembly”, “Major Wing Assembly”, “Tool Liaison” and “Special Tools”. Certificate: Front Range Community College GD&T ANSI Y14.5M-1994 (3 Credits) Certificate: Impact Management Program Certificate: Inventor Essentials 1 EMPLOYMENT HISTORY: July 2014 To Present (Software used SolidWorks & EPDM Vault ) Under Contract to, L3 Communications Westwood, Tulsa, OK. Design Engineer: Supported the Development Team in designing military Tactical Quite Generator Sets (TQGS) for the U.S. Army and militarized naval power distribution products for the U.S. Navy. August 2013 To Janurary 2014 (Software used SolidWorks & EPDM Vault ) Under Contract to, Davol/Bard, Warwick, RI. Senior Mechanical Design Engineer: Provided R&D support to the Development Team for ongoing Hernia Mesh Fixation Devices by analyzing current designs and proposing alternative designs to enhance reliability and design for manufacturing. Significant time was spent writing test plans, designing and setting up test equipment, performing tests, and writing final test reports for Design Validation Requirements. April 2013 To June 2013 (Software used SolidWorks, CATIA V & AutoCAD) Under Contract to, Peco Aerospace, Portland, OR. Senior Mechanical Designer: Converted PSU (Passenger Service Unit) Assembly 3D Model from CATIA V to SolidWorks. Provided Sustaining Engineering Support by processing ECN’s. April 2010 To February 2013 (Software used SolidWorks, PDM Vault) Sunbank Inc, Paso Robles, CA. Design Engineer: New Product Development, Injected Molded & Machined Connector Backshells & Accessories, Conduit Assemblies, for Commercial & Military Aviation, Vehicle & Ground Support applications. May 2008 To March 2010 (Software used Inventor, Pro-E, CATIA V & CADKEY) Glenair Inc, Paso Robles, CA. Senior Project Engineer: New Product Development, Designed Wired Cable Assemblies, Conduit Assemblies, Connector Backshells & Accessories, Vibration Test Fixtures & Assembly fixtures for Commercial & Military Aviation, Vehicle & Ground Support applications. April 2007 To April 2008 (Software used Inventor & CATIA V) Under Contract to, Icore International, Santa Rosa, CA. Senior Mechanical Designer: Designed Wired Electrical Junction Box, Conduit Assemblies, Connector Backshells & Accessories, Vibration Test Fixtures for the Boeing 787 Main & Nose Landing Gears. August 2006 To April 2007 (Software used Inventor) Severn Trent Services, Torrance, CA. Senior Project Engineer: Designed Automated High Volume Water Bottling Systems & Accessories, Project Management, New Product Development & Sustaining Engineering of legacy Bottling Product Line. February 2006 To August 2006 (Software used Inventor) Nor-Cal Products, Yreka, CA. Manufacturing & Design Engineer: Designed Custom High Vacuum Chambers, Valve Components and Accessories, wrote Manufacturing Work Instructions, provided Sustaining Engineering support for the Valve Assembly Line including, writing DMR’s, CAR’s, FAR’s and MRB Disposition. January 2006 To February 2006 (Software used Inventor) Under Contract to, Miyachi Unitek, Monrovia, CA. Senior Mechanical Designer: Designed New Generation Atmospheric Enclosure, including Automated Access Doors & Heated Staging Chambers. September 2005 To December 2005 (Software used Inventor) Coast Sign Inc, Anaheim, CA. Senior Mechanical Designer: Scheduled & Delegated Design Assignments, Liaison to Project Management. October 2003 To August 2005 (Software used Inventor) Under Contract to, Avant Premium Water, La Feria, TX. Senior Mechanical Designer: Designed Self-Service Water Vending Kiosk with a proprietary RO Purification System. 2 May 1994 To November 2002 (Software used AutoCAD & Mechanical Desktop) The Model Shop Inc, Longmont, CO. Owner: Owned & Operated a Contract Design and Precision Manufacturing Company specializing in Rapid Design, Prototyping and Short Run Production. (Detailed Project Experience Addendum Available Upon Request) November 1988 To May 1994 (Software used AutoCAD) Roecker Design Group, Denver, CO. Senior Mechanical Designer/Lead: Industrial Design/Engineering Consulting Firm, contracted to several high profile clients to Design & Develop Consumer, Medical & Industrial Products. (Detailed Project Experience Addendum Available Upon Request) Summary Of Contract Experience January 1980 Thru October 1988 Business Records Corporation, Boulder, CO. Senior Mechanical Designer: Designed Automated Optical Disk Library. Vactec Systems, Boulder, CO. Mechanical Designer: Designed Batch, In Line, Thin Film, Sputtering, Chemical & Vapor Deposition Systems, Vacuum Chambers, Cathodes, Drive Systems, RF routing, and Gas Distribution Systems. IBM, Boulder, CO. Mechanical Designer: Designed Re-circulating Automatic Document Feeder with Duplex Flip for IBM High Speed Photocopier. IBM, East Fishkill, NY. Mechanical Designer: Designed Functional Test Equipment used for Array Testing of Silicon Wafers. Technicon, Tarrytown, NY. Mechanical Designer: Designed Sub Assemblies & Components for Automated Blood Analysis Machine. EG&G Rotron, Shokan, NY. Mechanical Designer: Designed Sub Assemblies & Components for Automated Epoxy Powder Coating Machine. Branson Sonic Power, Danbury, CT. Machine and Tool Designer: Designed Sub Assemblies & Components for Ultrasonic & Vibration Welding Equipment. IBM, Fishkill, NY. Mechanical Designer: Designed Reactive Ion Etching System. Martin Marietta, Orlando, FL. Aerospace Tool Designer: Designed Machine, Check & Drill fixtures for Night/Day Vision on Advanced Attack Helicopter. Nova-Tech Engineering, Edmonds, WA. Aircraft Tool Designer: Designed Interior Fiberglass Bonding Tools and Assembly Fixtures for Boeing 757 & 767. Thompson, Miller & Lyons, Seattle, WA. Aircraft Tool Designer: Designed Machine, Assembly, Check and Drill Fixtures for Boeing 757 & 767. End of Summary Of Contract Experience January 1980 Thru October 1988 August 1977 To January 1980 Boeing Commercial Aircraft Division, Everett, WA. Aircraft Tool Designer: Designed Assembly, Drill, Major Airframe, Major Wing Jigs & Fixtures, Portable Drilling & Fastening Equipment “Special Tools” & Tool Design Liaison for Boeing 747 & 767. 3