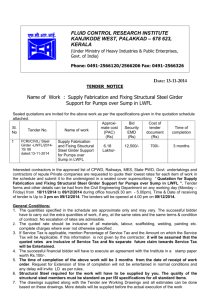

Draft Tender Document

advertisement